Now that Jasic has released their own line of CNC tables, can Langmuir, who specifically recommend the Razorcut 45 request the data from Jasic to be used here?

Welcome,

First a cut chart will only work with the torch it was made with. If your using a different torch then the cut chart is not going to work well. As of right now there are many people using the Razor 45 with as many as 6 different torch’s so you can see this would cause a little bit of a difference in your settings.

Now the Razorweld 45 that Jasic is using on there CNC table is using a Chinese copy of a TM125 - 125 amp torch. They should be using a TM70 , X45 CNC or a PTM60 torch, these would more suited for that plasma cutter as its only a 45 amp unit.

Thanks for that feedback. It seems here the Jasic team are offering the SC80 torch in machine configuration, using the same consumables as the SC80 hand torch which is rated max 80A and seems to ship with the 45A models. So thought it might be good to get a ball park set of “feeds and speeds”, as the original cut charts were pretty light on.

Yes I have seen that torch offered being used on the Razorweld 45 also. Think of it this way the smallest cutting tip I offer for that torch is 0.9mm/40 amps and that is a shielded tip. The 1.0mm/50 amp tip is the smallest for none shielded. Those would both work. So unless you can get some Chinese copy smaller tips you can forget doing fine detail work.

Hi mechanic416, yes you re correct the 0.9@40 maxA 1.0@ max50A and 1.3@ max65A are the main consumables.

I use from COBRA (Italian) and are made to high standard. I do very little fine work, mostly some signs around 1.5mm (16GA?) most of my work is the 3mm to 16mm range.

The earlier brackets that were shown was cut from 8mm plate. In looking at the original skimpy material the Jasic guys suggest pierce at 4.5mm, cut at 3.0mm wound up to full 45A, no pierce times (or limited) and no lower amp options.

So was just hoping someone may have access to the data because introducing a table with you machine requires a bit more research I would humbly suggest.

Thanks for this info! Will see how it lands. ![]()

Hey FSFab, noticed the bottom is missing on the carbon steel page, would you be kind enough to re-post or if easier do you have a link to it?

That is what was sent to me as is from the troubleshooting guy at Jasic. I assume that Jasic sent it that way because that is all that is recommended to cut with the Razorcut 45. The rest of the charts are probably for a larger amperage machine.

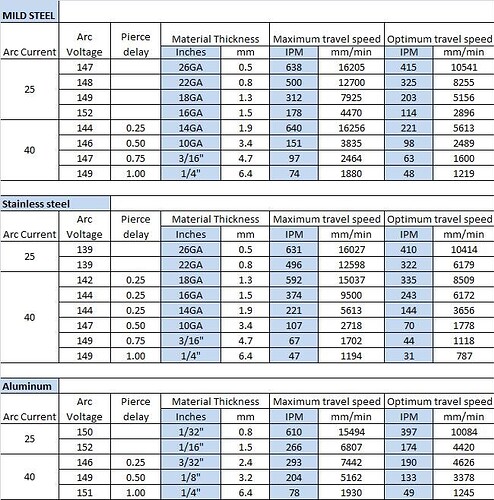

Here is the chart that the entire Langmuir forum has been using for years. We are killing a dead horse.

I see what your are saying. The other two have .75 thickness at the bottom and that one should probably have it too but it is cut off. That is what I received in my email though I do not have a link and the original image I have is cropped that way unfortunately.

I respectfully disagree. There is a little more information on these charts from Jasic and I was having problems with my arc going out after the pierce with the settings shown on your chart. This chart may help people that are experiencing the same problems I was having. I do have to test more metal thicknesses though. I was cutting 3/16”.

This is a guide. If you have been following this, you should be able to do it. That chart or your chart is to get you close. Voltage to the machine, the work clamp connection, and 10 other factors will vary your cut speed. I will stand back for now. I wish you luck. Respectfully.

Yes, I understand that. I can send you my initial post where I was having problems if you would like to look at it and give me insight. I was testing various cut speeds and pierce delays and couldn’t get my machine to continue the cut after the pierce. With a pierce time anywhere over .5 seconds I could not get it to continue my cut. Plasma_bot also asked for Jasic data which I provided.

Here is my original trouble post: Cutting Voltage Lost During Cut Crossfire XR

Thank you

Well, it seems you are very thorough. My contribution would be to see if the table will pass the ground loop test with an ohm meter.

It could be EMI or a ground loop issue. You have tried new consumables, you have a good air compressor, dry air, and analysis with different settings.

A ground loop will lie to the VMI and tell FireControl to do stupid stuff.

I will have to try and figure out the ground loop issue. I am not very savvy with electrical stuff so I may have to get a buddy over to check it out.

The table frame needs to be totally isolated from the control box. Use an ohm meter. It should be an open circuit almost nothing.

If you do get a reading try unplugging cables till it goes away. Also make sure the control board usb plug is not touching the case.

Thank you for following up, much appreciate the effort.