I was looking for the thread where it explained the machine settings but couldn’t find it yesterday. I remember reading it but not the settings…

it didn’t do it on the helmet i programmed in sheetcam only the download and print jobs from fireshare

I was looking for the thread where it explained the machine settings but couldn’t find it yesterday. I remember reading it but not the settings…

it didn’t do it on the helmet i programmed in sheetcam only the download and print jobs from fireshare

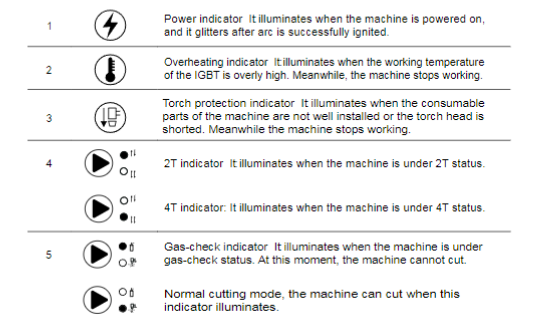

Presumably it should be in 2T, not 4T?

Yes. 4T means you turn the torch on with a momentary click and release and it keeps firing until you click the trigger again. 2T means that you have to hold the trigger on for it to fire. When you release, it stops firing.

I looked at those icons they use and it is kind of understandable when you have it explained but there should be a better symbol that would explain the switching mechanism.

Done! Thank you Jim.

The new 20G tank arrived and I installed it, the vent… and I labeled everything. ![]() I am afflicted a bit…

I am afflicted a bit…

Yes I knew it would fall out but you can 3m it in place. It’s the only way to make it look right. I just didn’t know if it would be too small.

I think the size is about right. But, several of the parts fell into the water table so I’ll have to drain to get them out.

You are in the right place… you will fit right in. The only thing I ask is keep the prices of upgrades off the forum in case the boss reads it. ![]()

![]()

@72Pony Erik, shhhhh… don’t talk so loud. She will hear!!

Not that my welds are normally beautiful, but I ran out of gas. ![]() Amazing how much worse they are without. And, there was an error in my sketches for the design, which oddly carried over as a second cut for the holes with the lead in the wrong way. Oh well, function over form. Not worth fixing it. Just learn.

Amazing how much worse they are without. And, there was an error in my sketches for the design, which oddly carried over as a second cut for the holes with the lead in the wrong way. Oh well, function over form. Not worth fixing it. Just learn.

Touch screen Crossfire Pro!

As president of the club, I would like to formally welcome you to the grinder club. I have a card with your name on it… just send me a shipping address. You are taking @ChelanJim place… he recently graduated from the club. As a club, our finances, like our welds… are low budget… so I hope you will pardon the fact I just scratched Jims name off and wrote yours over the top. ![]()

![]()

BTW totally joking… nice work… sometimes those simple brackets are the most fun things to cut. You see a need and realize… I got this!!

You can’t kick me out of the club. I had one decent weld out of 100. I am not leaving!!! ![]()

We need to get shirts. Something like “Our welds are our bonds” or “Don’t laugh, it holds”

@72Pony @ChelanJim ROFL. I really did run out of Ar/CO2. I snuck out today and also upgraded my bottle to the 120 size whatever it was the guy said. Now my welds can go back to really ugly, but strong, instead of really terrible, ugly, and strength questionable.

Thanks for the laugh gents. And for the club membership.

I also stopped by the steel supply and ordered two full sheets of 4x8, cut in half 18 and 11 gauge. Plus, raided the rem pile.

#uglyweldshavefeelingstoo

Next I’m going to design a keyboard and mouse tray that sits under the monitor.