me thinks the “fix” was not engineered. It was guesstimated.

Also, some may not be interested, but I did get my Dell P2424HT Touch Screen Monitor working on a late 2014 Mac Mini hacked with Monterrey. It runs FireControl very well. I need to adjust response times, but its usable as it is tested yesterday.

My plan is to cut a special VESA mount for the monitor to hang off the back right (when facing) of the machine, but in my case, facing backwards. It will also hold the Mac Mini. The keyboard and mouse are wireless BT, so I can use the keyboard to jog from anywhere around the machine.

I learned Sheetcam. Now to go outside and fix the machine. And get a beer. Probably get a beer first, tbh.

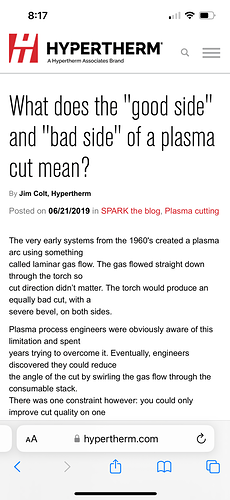

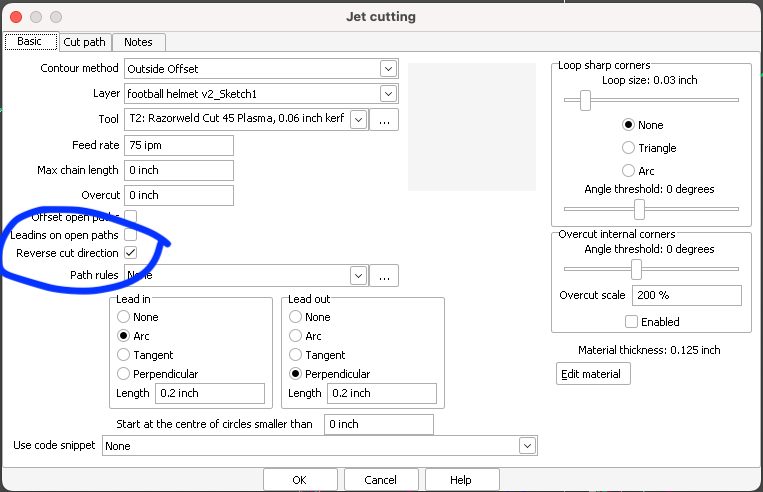

Check your cutting direction…

Inside cuts - counter-clockwise

Outside - clockwise

OK, I loosened all of the bearing carrier blocks, jogged the machine, then methodically went through tightening, just barely, the grub set screws, then the blocks and it no longer slips. So, it was binding. Even still, super frustrating because I could move it with a pinky finger during the build.

I set work zero, that works.

Next problem is — I cannot update the machine firmware because I do not own a whimdose machine. The lack of the support for linux/Mac OS is… uh… questionable, and frustrating. So, the Limit Switches are a useless waste of money. Not really needed on this use case as others have pointed out. But, still…

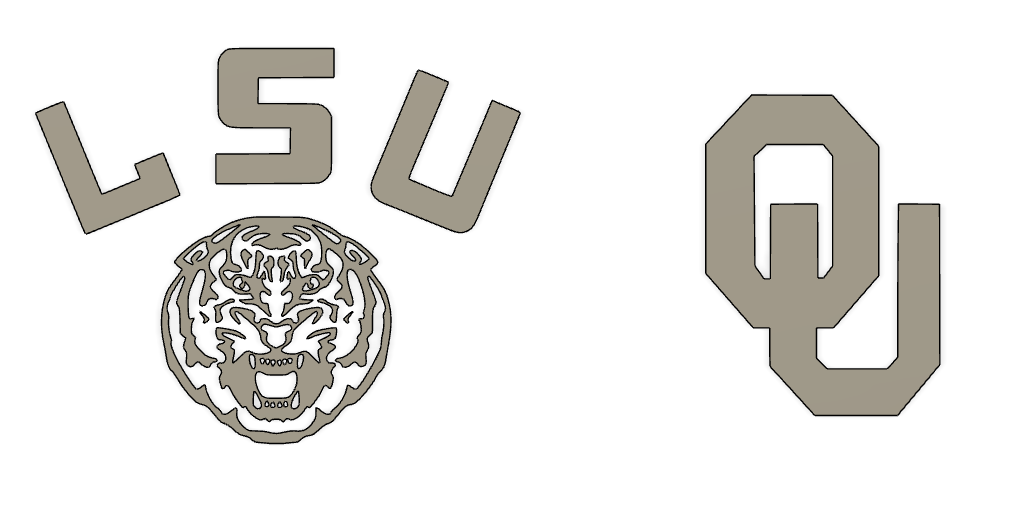

Off topic but what football team are you working on with helmets?

I did a light Lions helmet a few months ago…

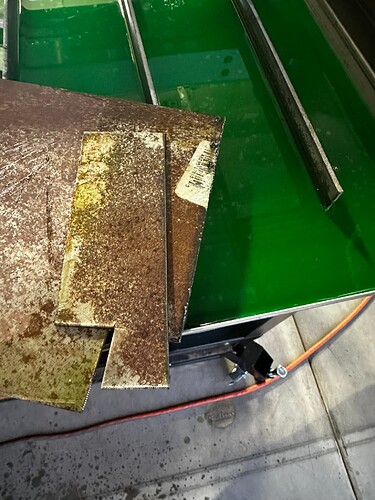

My first cut ever on the Crossfire Pro! Just a manual cut using jogging, 30amps, 100ipm, the Razorweld is set to ~82psi.

Don,

Your model is actually the exact same one, I downloaded from Fireshare. So, you are the inspiration here buddy! The first one is going to be a damn boomer sooner OU helmet for my redneck wife. Then, a proper LSU Tiger helmet for me. Then another sooner or 12 since I know so many of the annoying 'necks.

I looked up how to do this. Layers and tedious work. Joy.

What happens if I don’t bother? I mean, when I downloaded your file I thought I was getting a Lincoln, not a chevy!! ![]()

Just what is recommended…

Reason I didn’t add my Lion in fileshare is

because it’s a logo. One thing to make a sign for yourself but posting for others can copy is something I try to avoid. If you need help just message me.

I do all my CAD and CAM on my 16" Macbook Pro, beast. Then I copy over the jobs to the mac mini in the garage workshop.

ya wife has a cricut machine. I may cut the OU logo and make it pop like yours.

Agree, the Langmuir motion system isn’t the highest performance, nor does it need to be. It does work covered with plasma dust and water. Plasma cutting doesn’t put force on the motion components. For me, it’s just another tool that has its quirks, abilities and limitations. Glad you’ve got yours cutting, have fun and keep posting your projects.

Your t2 / t4 switch might be in the wrong position on your plasma cutter.

Looks like you’re rapids are being cut.

Just assuming that’s what the blemishes on the knife blanks are.