And also this happened…

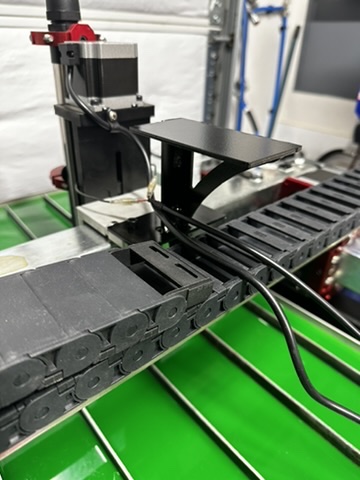

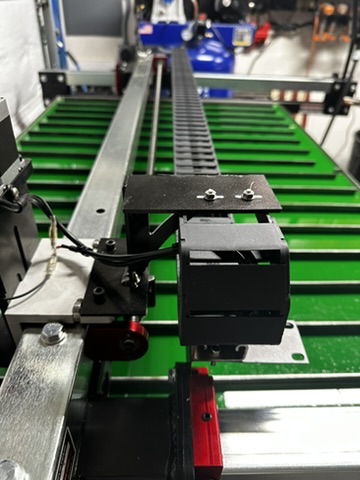

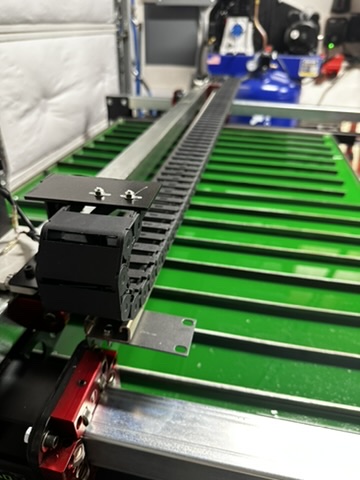

My custom bracket to hold the top of the cable channel carriage.

Nice build mods.

Also looks to be another raptor pickup owner, I have 2012 gen 1.

Gen Deux, Cobb Stage 2, 550hp, 650tq

Well, I fired up the machine last night for the first time. I have the @#$% slipping couplers problem. The X and Y axis’ moved very easily after tuning during the build. The couplers are crap. Actually, the bearing rail system design is crap too, but cheap I guess. I may convert it over to a linear bearing rail out of spite for crap engineering. Very disappointing to go through months of methodically building this machine only to be let down.

I’m going to loosen all the bearings today and see how it performs. Still though, not even a three star experience Langmuir. This is my fifth CNC machine. My second was a custom 3D printer that I built from scratch. I need this machine to build my next machine, a CNC router/mill.

These couplings are not the best for sure. The forum has proven that many time. Just because they slipped I wouldn’t readjust the bearings if you think the was ok during assembly. I would try to tighten couplings and also make sure motor plugs are in good as well. Do that with the power off though.

Did you have any binding or just noticed a slip?

Oh and some silicone spray on the lead screws are your friend.

I marked the screw and coupler, they are slipping. It works with small increment movements, and slips on continuous or large increments. I removed one of the couplers, checked it, reinstalled and same result. I have tightened the crap out of all of them, to the point where I stripped one of the allen heads. Plugs are good.

They are cheap for sure I stripped one one in the middle of the night. For a quick repair I made one the order the recommended one from the forum. Yet to put them on. Add a little lube to the lead screws see if that helps. I never run mine dry. I use spray silicone by liquid wrench.

Sorry you are having this issue.

I have this product but have not used it yet. What I read was it is for helping smooth surfaces hold together like a bearing collar and the housing. Perhaps this would work at the couplers.

https://a.co/d/etOVWdy

This is the coupler many who have had problems ordered this to fix the issue:

Yup thanks Jim, I read the other thread. Going to try retuning first

Did Langmuir state using this design coupler because my machine came with what looks exactly like that photo and they seemed to work really well. I got my pro like 6 months ago so maybe I got a new release or they ran out of the crap ones but I’m thankful non the less

the ones that came with my machine also look exactly like those in the Ruland picture.

@mg6studios Are yours steel or aluminum? The original couplers were aluminum and would strip if you tightened them too tight.

I had heard that they had changed them to more robust couplers.

This is what mine was shipped with and what have been working fine since I tightened and secured them with thread lock.

But you bring up and interesting point: If Langmuir is now using them that could be one of the reasons the price shot up. I bought three of the ones recommended (just in case - prepper) in March of this year and paid $14.19 each. You can’t touch them for less than $40 now.

Mine are exactly as pictured in the Ruland type… dunno why mine are different.

Yeah mine are exactly what is pictured in the Ruland photo and they are steel with 4 set screws per coupler. But they are tiny screws and I’m sure they can strip easy enough. I just wasn’t sure if they had newer style they were starting to send out after a certain date.

me thinks the “fix” was not engineered. It was guesstimated.

Also, some may not be interested, but I did get my Dell P2424HT Touch Screen Monitor working on a late 2014 Mac Mini hacked with Monterrey. It runs FireControl very well. I need to adjust response times, but its usable as it is tested yesterday.

My plan is to cut a special VESA mount for the monitor to hang off the back right (when facing) of the machine, but in my case, facing backwards. It will also hold the Mac Mini. The keyboard and mouse are wireless BT, so I can use the keyboard to jog from anywhere around the machine.