Start building test buckets for the drain and chip collection. Just 5gallon buckets with a valve installed the a screen mesh on the drain then a stand with a 200 wire stainless steel mesh that will get siliconed into the bucket. I will build stand that the bucket sit on and will drain into the provide bucket with the pump in it. If this works well I will most likely build a pull out tray setup.

I too am looking for a way to pivot the monitor and tuck it away when not in use - I like the look of your monitor arm, mind sharing what model it is? it seems to fit well, any pivot issues?

Cheers,

Mike

Yeah I agree that monitor arm is sweet, I have one I want to use but that one is way cleaner mounting.

HUANUO Monitor Wall Mount Bracket–Articulating Adjustable Gas Spring Single Arm Stand with VESA Extension Kit for 17 to 32 Inch LCD Computer Screens - VESA 75x75,100x100, 200x100, 200x200 https://a.co/d/bCUQB5U

Loving this build. Definitely want to copy your idea of moving the drain system around… I was debating adding some spray nozzles at the back of the machine to move the chips forward and having a deeper valley at the front for chip/coolant catch. and setup on top of a tool chest is brilliant! Just wish I could weld.

do you have a link to those particular shower drains? I’ve been looking and it seems difficult to find that style…

Neodrain 24-Inch Offset Side… https://www.amazon.com/dp/B07DN7CBZ8?ref=ppx_pop_mob_ap_share

My compliments on your build. I am about to start my build, can you explain how you will reach and level the third base plate? I think that is an excellent idea, look forward to seeing that.

I did re-invent Langmuirs entire cable management scheme on the Crossfire Pro from a pole to a x-y cable chain scheme. I see they incorporated cable chain into the XR and I am hoping there will be ways to do that with the MR1.

Watching with interest! Thanks

@AE95 also…

I had a similar idea of a internal frame for a palette jack instead of a platform for the machine to sit on that was mobile. I was thinking for my needs I would have to build it 90 degrees from how yours orients, but I am still contemplating. Are you going to put casters on that? What do you think of the work height of the table? I was thinking it was kinda low but I haven’t put that question to the forum yet.

Thanks,

Kyle

Kyle, there is a build where a guy shows how to do it. You rotate the X axis around 180* and machine the back to final depth then rotate it back and finish the front.

I made my base plate 1 piece out of 3/4” 31x24 6061

Ok thanks, I’ll search for that build. Is that on these forums? If so I must have missed it.

I have a pallet off another CNC machine that I think I will probably try to make use of for this. It is T-slot based but for mounting things outside of the standard work envelope like a 4th axis, I think that would work good.

Thanks!

Sorry for the late reply Kyle. I have no plan to install casters that is the point of the pallet jack. Working height is a little to high but only if needing to work near the back of the machine.

Life got crazy and had to put a hold of finishing building my MR-1. Finished the wiring guide making a tee and 3d printed some covers. Then 3d printed a guide for the harness coming out of the mill head with added holder for the touch probe.

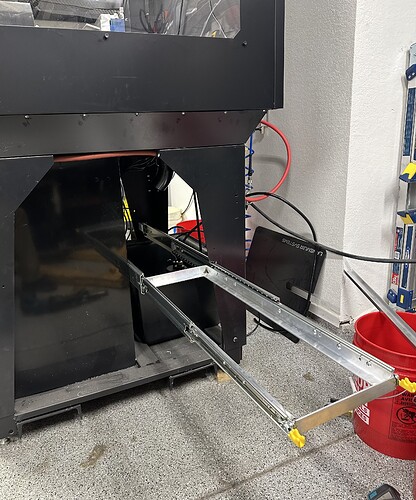

Started some CAD to build a chip tray. Will be mounting it in sliders so it can be pulled out to clean out the chips.

Very nice build!