I so want an MR-1. But have to keep reminding myself, no room for it, and just turned 68, I need to stop buying all these expensive toys, as the kids not interested in this stuff. Will buy bourbon, beer and steak instead! lovely work being done here, keep it coming! ![]()

![]()

My kids could careless too. Just turned 67 myself. I am enjoying it. Its a great machine. Mine works perfect. If I could do it over the drain system absolutely s%^$. I would have installed 3/4 inch drains on all 4 corners. I like bourbon and beer also…

I know where you’re coming from. I’m thinking my shop stuff is going to go for a song when I die. The kids won’t want it and they won’t be interested in getting the price it’s all worth. I may will it all to a makerspace instead.

Exhaust flange for a Ford Kent Crossflow out of SS304 (cylinder 1/4, 2/3 get a combined flange). Complete overkill for the application probably, but I went down a rabbit hole once I started drawing it. Transitions from the port out to a 1.5" primary with a step to locate said primary. Cutting went well, and I was impressed with the finish on the part. I did mess up the flip somehow, so it has a step on the outside profile. Not ideal, but not the end of the world as far as screw ups go.

That looks nice! What tool did you use on the conical section? Is that from a ball mill with low stepover and stepdown, or a tapered endmill?

Thanks! First one, 1/4" ball mill with lots of step downs lol

VERY cool!

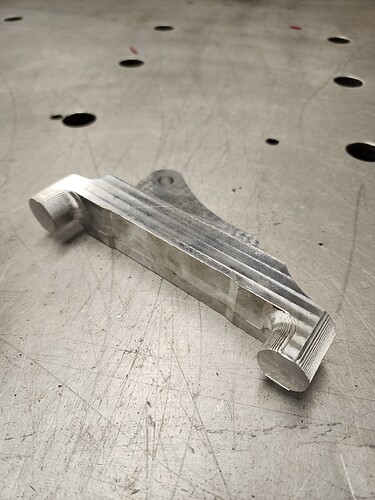

Harley knucklehead kick start arm. Not quite done yet. Very happy with the results. Needs more sanding and polishing…

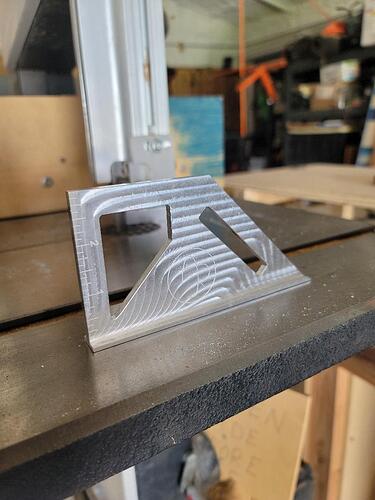

Proof of concept for adapting Wilwood 4/6 piston caliper to Volvo 240 front brakes. Has some issues lining up when part flipped. Need to make a fixture to finish the two bosses and tap for studs.

Beautiful!

What size endmill did you use for the fillets at the larger end?

1/4 ball mill. 3D contour with .004 stepover. It has been sanded and polished.

Fantastic Job, well done

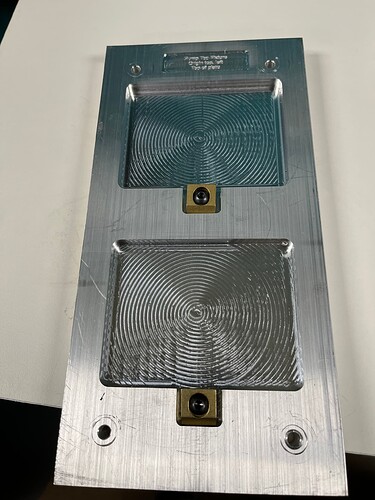

made a AN fitting bulk head for our race bug. hated having to sometimes hold the backside to keep it from spinning, so now this fixes that ![]()

and some cup holders lol

You have a race bug .Nice I would like to see this I also have a 1966 custom bug in the garage

Well that’s just awesome! Great to know that it’s going to have some MR-1 machined parts on it soon!

already does ![]() but yes, will have much more now too

but yes, will have much more now too ![]()