This looks amazing!!! More instagram posting content ![]() . Keep it coming folks!

. Keep it coming folks!

Its on my instagram @masonthedriver

heres the link

Thanks Mike! ![]()

Yup, that’s a cool piece!

Thanks Carter ![]()

these look amazing, one thing i would add is to cut recesses for the nut section. makes it nice when tightening and loosing, so you dont need two wrenches

Thank you ![]() Great idea. Although I almost did that but laziness took ahold me. So I decided to pay for it later and wallow in self regret when I do the final assembly and later down the road maintenance on the car

Great idea. Although I almost did that but laziness took ahold me. So I decided to pay for it later and wallow in self regret when I do the final assembly and later down the road maintenance on the car

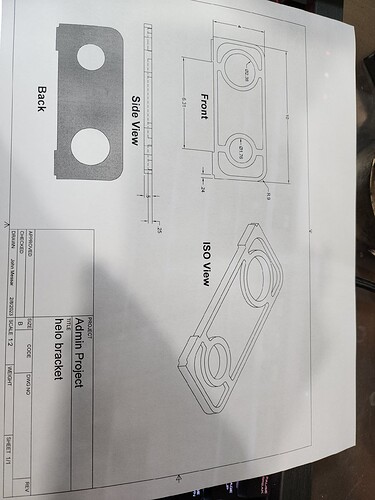

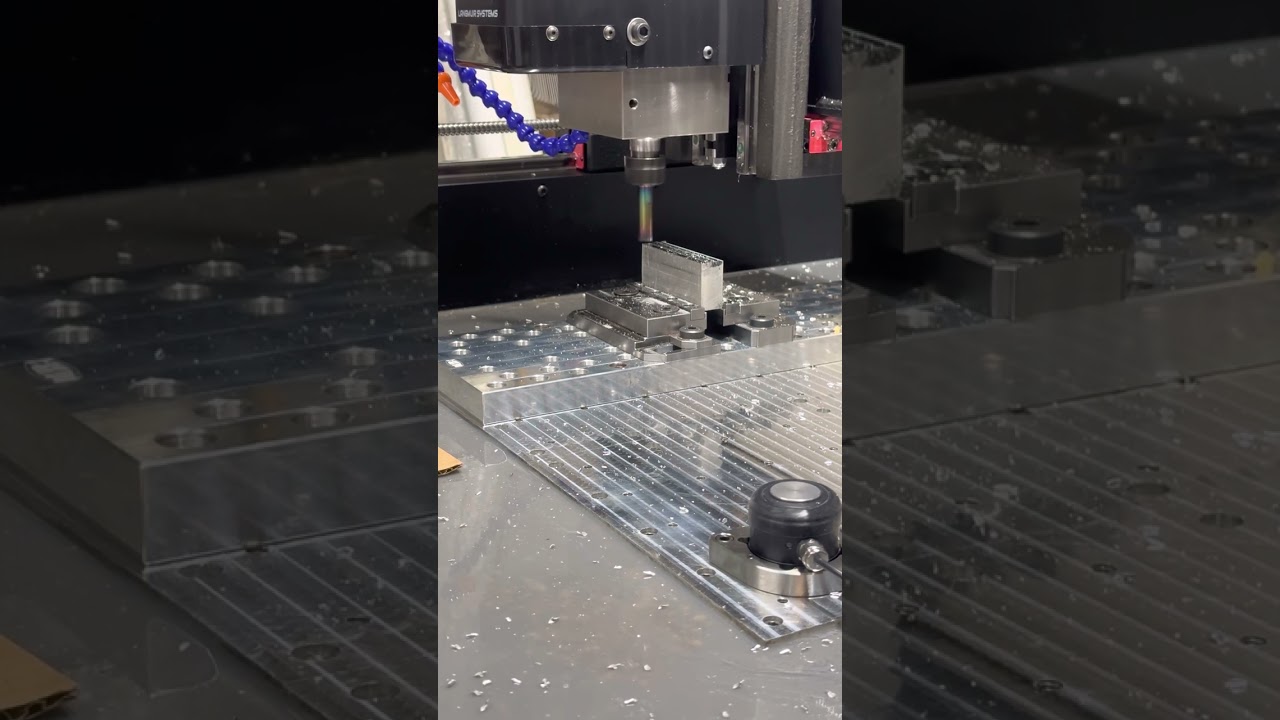

Made a fuel bracket for a helicopter crop duster this morning. It

came out awesome and in spec.

Several more parts in fabrication stage.

Will post finished product.

Basically this device attaches to the landing gear of the helicopter. It will have small versions of what looks like a nascar fuel fill connectors. When the helo lands on the support truck, fuel gets pumped into the fuel tank and the large fitting gets herbicides pumped in. This whole operation take several minutes. Helo takes off to continue crop dusting. Its wild to see. These guys have balls of steel. ![]()

Thats awesome! Looks good and cant wait to see it assembled.

Sometimes I do a little crop dusting myself in elevators with big tech company employees inside lol

That’s cool, nice job!

Easy Valentine’s Day gift for the wife. She said she loves it.

Suppose a picture would help! (Other side is the same)

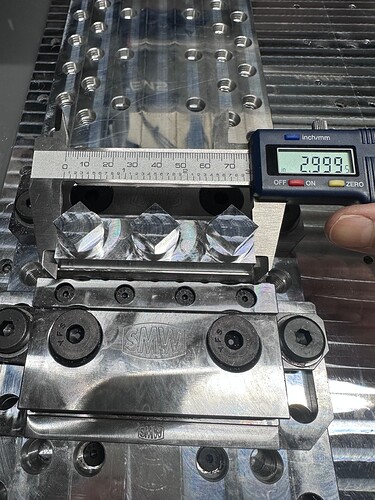

Great job. How did it come out vs the spec’s?

That’s some tiny endmill work.

Perfect match to the original involute gears. 1/16” endmill fit the radius on the root just right. 1.75ipm feed, .0625doc, .0001chip load. Slow and steady works best after breaking numerous bits ![]()

Looks really good ![]() What size stock did you start with? Did you turn it down on a lathe first?

What size stock did you start with? Did you turn it down on a lathe first?

I acquired a bunch of 3” round stock 2” tall with a 1/2” hole in the centre. Cut one in half on the bandsaw, then cut some parallel cuts on the good face to set in the vice, probed the bore(with the limits disabled ![]() ), faced it off and ran the program. Roughed out with a 1/4” endmill and finished with the 1/16”.

), faced it off and ran the program. Roughed out with a 1/4” endmill and finished with the 1/16”.

This looks awesome!!

Finally this is the first test piece that I designed in Fusion360 for hobbyist.

I did a surfacing operation with 1/2” endmill 2 flutes and subsequently I loaded a contouring and adaptive clearing operations with the 3/8 end mill and all the suggested feeds and speeds from Langmuir. I was happy not to crush the machine first of all. The process was a bit slow but got great accuracy.

I used the probe and tool setter to define origin and calibrate both tools and all was smooth. Pretty happy.

Looking forward to the new version of cut control.

You can see both operations on youtube here( wait for the high quality video to be ready on youtube.)

Really happy with the accuracy as well.