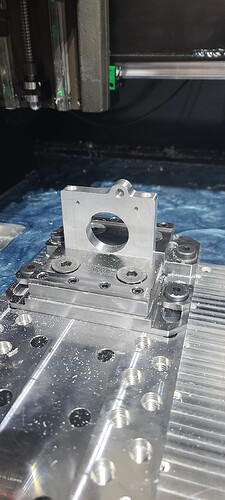

Working on some upgrade parts for mine this weekend. This is the X axis motor mount with a Nema 24 instead of the Nema 23’s, and the Automation direct homing switch mounting point. Already have closed loop steppers on my Y axis so this is a simple easy part to make for the X axis.

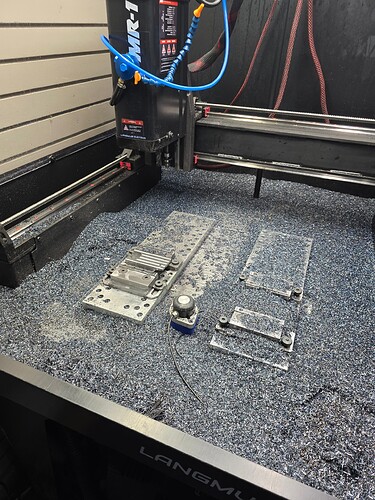

Milling some custom fingers for my Titan. I’m not a fan of the tapered design. They are also really fat so I reduced the thickness of tips.

Still need to do the radius and bores for the pins.

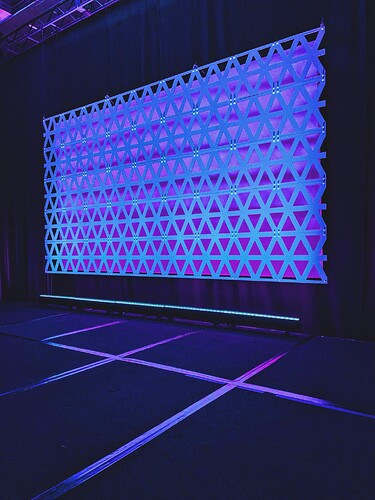

This was was my first part / project for my MR-1!

Its a 9’ x 16’ wall made from 66 panels (22.5" square), connected by basic 4 hole pattern plates at each corner. It was a fun challenge, and the strategy worked well!

It was setup as a feature wall for a live event.

Here’s hoping I get to make many more features like this one!

Very impressive.

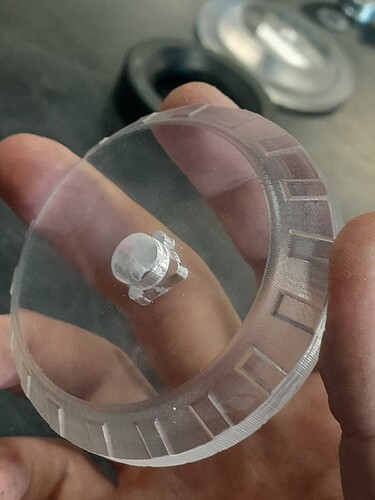

Reversed engineered this sort of tube plug clamp, machined out of acrylic. This was one of my first parts with 3d surfacing, and coolant was a big help with the surface finish. The holes n the outer edges were done with a laser cutter.

Made up a custom height shock spacer for a friend with a motorcycle shop. He was in a bind and I was able to get it to him the next day.

Is that a full set of #1-#9 putters? You can add a ‘big bertha’ 1 putter… ![]()

A little testament to the small diameter accuracy of my machine. I recently machined an optic cut on a pistol slide. #6-32 threads, and squeezed the pocket between the ejection port and rear sight dovetail to maintain stock sight function. All 4 lugs were within .0005" diameter and made for a perfect fit to the optic.

I’ve been trying to think of something new to make. Those battery tie downs may have sparked something ![]() .

.

Nice work!

thanks, it takes a couple different tools but worth it

have the Titan coming tomorrow, but no punches. cut this on the mr1 today. nice simple punch for the brake.

Your cheating.

Mount for custom snowbike project I’m working on. Biggest piece I’ve done so far. Few apprentice marks, but it’ll get the job done

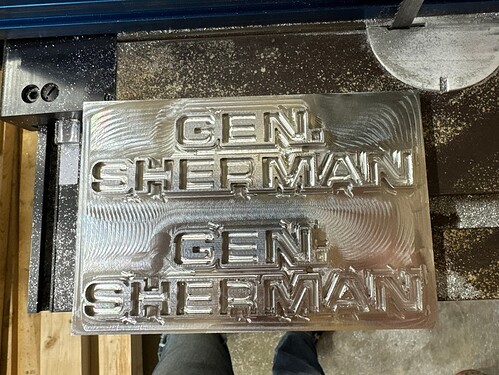

Been lurking the forums for a while, slowly getting my machine dialed in. My main project is cutting custom aluminum vehicle emblems for a friend of mine, thought I’d share a few of them. These take anywhere from 3-9 hours, finishing with a 1/16" endmill to get all the small details in them. It has been fun learning how to program CAM for machining - previously just done 3d printing and 2d cnc for woodworking projects. I just cut the emblems from stock and hand off to him, he adds the powdercoat and polishes them up.