That IS really cool!

I didn’t like that warping of that PHA.

Neither did I, but there is always a way to counter it. ABS/ASA is horrible about warping on long stretches also.

Agreed about ABS. I have not done anything with ASA larger than about 4 inches diameter on the build plate so I haven’t noticed it yet. I do know it will, but so far it seems less than ABS.

And, I am sure the Brand makes a difference. The ASA I am using is FlashForge and so far I am impressed. ABS was primarily Sunlu.

I had problems with printing ASA warping on larger spans. I turned the plate temperature to 195 C from 170 C, and the problem disappeared. I guess keeping it hot inside the enclosure is the secret.

And slow cooldown.

Happy wife!!! She gave me an assignment: “I need a way to display my bracelets at the craft show next weekend.”

I find this model in MakerWorld:

https://makerworld.com/en/models/633053?from=search#profileId-558100

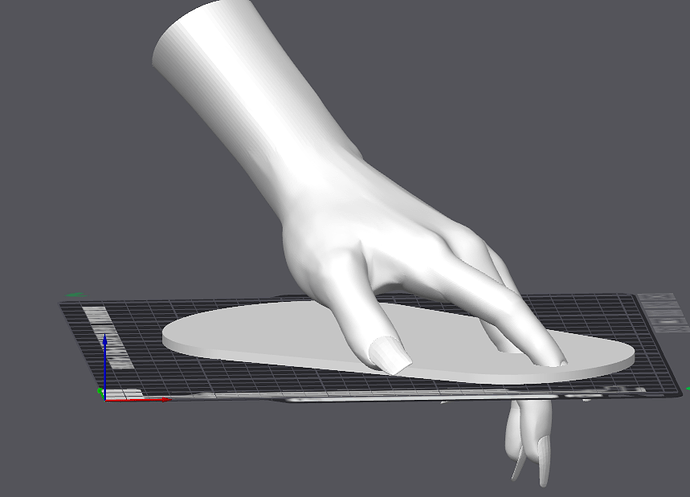

I create a simple base and reorient:

Added supports, perhaps more than I needed. 3 walls, 5 bottoms, 4 tops with 25% gyroid infill. I used GratKit PETG Transparent filament.

She is liking my new printer!!! Oh yes…

Edit: 12.5 hours printing 0.02 layer height.

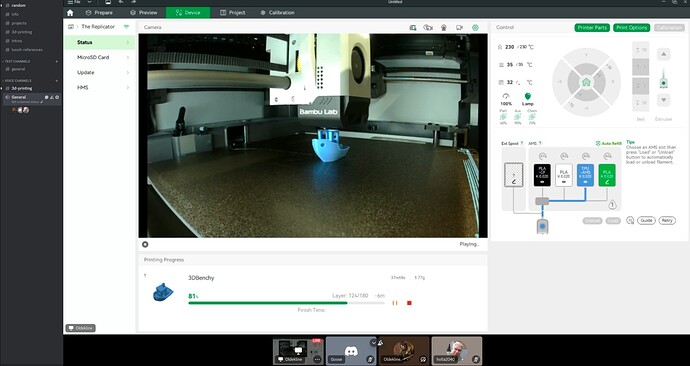

30 hrs later. Good job Jimmy ![]()

Well done indeed.

https://all3dp.com/4/bambu-lab-to-release-for-ams-compatible-tpu-filament/

Another exciting development from Bambu.

great news on AMS TPU!

It’s been mentioned before but the liquid glue from bambu is a great product for bed adhesion.

That is many many little parts of petg all sticking perfectly. It makes my days 3D printing much happier

https://store.bambulab.com/products/tpu-for-ams

TPU for AMS

I want to wait and see what you say after you try it!!! You are our canary in the coal mine, so to speak.

The brief review that Tin referenced gave me pause:

While there were a few difficulties with getting a printer to recognize the material and with layer adhesion at 240 °C, Vorkosigan78 writes that printing at 245 °C resulted in a part that was “noticeably harder” than TPU 95A.

Drooping was noticeable, especially under bridging, and multi-material adhesion with PETG was good, but not great.

PRUSA may be behind the curve, but they took a step forward where Bambu has not yet. Actively heated / thermally controlled enclosed build volume coreXY

(WHY can’t printer manufacturers prioritize a CUBE build volume???)

I appreciate the post and Prusas effort.

About time ![]()

![]() The Bambu X1-E was release in October 2023

The Bambu X1-E was release in October 2023

https://bambulab.com/en-ca/x1e

Product Features

- Secure network connection

- High-speed CoreXY

- Active chamber heating

- 320°C max nozzle temperature

- AI-powered print failure detection

- Powerful air filtration system

Here is a link to when I tried to go the Prusa Route.

Prusa is as dead to me as Apple.