Yes. Here’s my first crack at it:

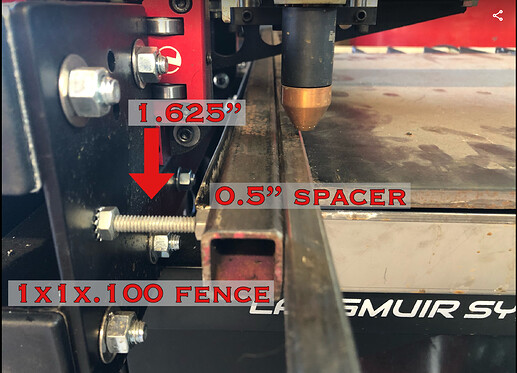

I found I needed to use an additional removable spacer between the fence and the sheet. Otherwise the fence would be in the way of the torch. Not ideal. The fence stays in place, when you want to load a sheet, put the spacer on (it’s 1/2" stock), put sheet on. Remove spacer, cut. Put spacer back on, slide sheet to make indexed cut, remove spacer, repeat. I’m open to better ideas.

I (think have to double check) the length is 51-1/2", holes were drilled 1" from the ends, 2-1/4 2-1/2" long 1/4" bolt (or 1/4 machine screw) is used. Needs to be threaded full length. Holes were drilled 1" in either end on the stachon plates.

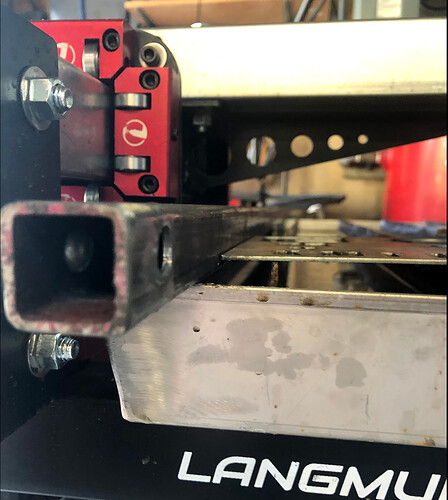

With the 1x1 resting on the water table, sheets will be high enough that you don’t have to worry about the rounded 1x1 tube edges, they meet on the flat:

There is approximately 1.625" between the stachon plate and the 1x1. Didn’t take too much fiddling and I got it to within 0.001 either end of travel

Oh to be clear, I think we might be thinking of two different things when it comes to indexing. I was more thinking along the lines of making cuts greater than the Y axis travel. So you have to break the cut up into multiple parts, and slide (index) the sheet along the Y axis. That’s why I wanted a fence. Less so for positioning in X.