Here is the dfx file, I had the compensation set to center but it still starts to the side of the line, I had the pierce clearance at .055. Where do I see what my pierce delay is set at?

Plow.dxf (116.4 KB)

Pierce delay is set at .5 sec

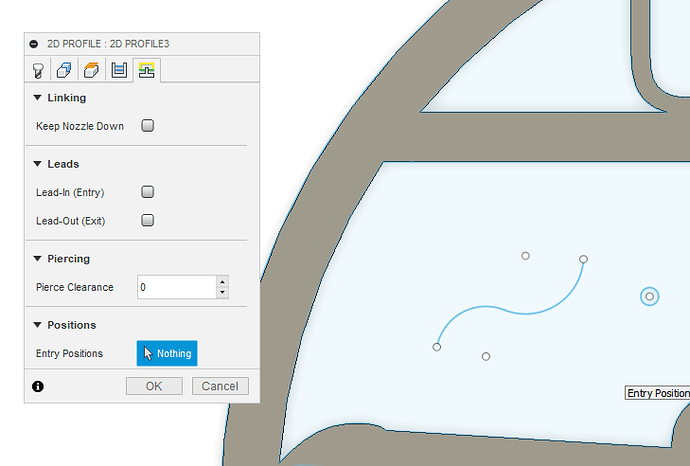

for the line cutting part this need to be set to zero.

Without a F3D file i can not see how you have done your set up.

I took the DXF file and ran it though F360.

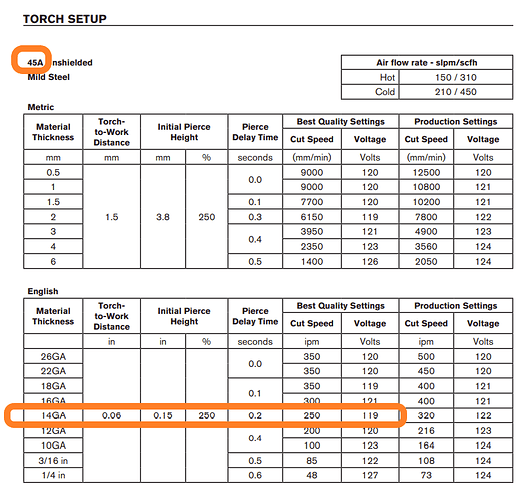

Here is a F3D with a parameters set up how I may go about it. I assume 14 gauge mild steel as the material.

here is and torch setting I used

udot shed 4484 v1.f3d (603.1 KB)

udot shed plow 4484.nc (114.6 KB)

Cut file

Good, now when your about to run this program dial back your pierce delay in firecontrol to 74%

Let me know how this pans out.

Ok I’ll try it. I did use 14GA steel. So I don’t know what a f3d file is or how to send it. Also which of these settings is causing the hole at the end of my lines? Or is it a combination of them. Thanks for the help.

This post goes through how to export a f3d file from Fusion 360.

This is a video that also explains the exporting of an f 3D file.

I’m not sure you’re F3D file will tell me more.

What kind of plasma torch setup are you using?

I asked cuz some torches just aren’t quite as quick with the “torch off” signal.

It’s the razor weld 45 and it’s just a regular torch handle and the consumables that came with the machine.

Also when I got it the two ports to run the torch from the machine were backwards and so I had to plug them in the wrong ports to make everything work.

That’s happened quite a few times with the razor weld. Doesn’t do any damage to the machine but it’s inconvenient for sure.

How much use has those consumables had what does the nozzle opening look, like is it still perfectly round?

Not sure how round it is, but I have been experiencing the hole since my first cuts, also I want to say when I used it last fire control said it had 350 torch fires.

if it is not round it is done.

take a close up picture and post it .

are you running a .06 cutting height?

I check it out tonight.

Is the cutting height the same thing as clearance height? My clearance height is 0.04in.

They’re not the same thing.

The very last page in fusion 360 when you post your NC file that’s where the cut height information is located.

Ok mine is .063in.

That torch height sounds good.

I would put some fresh consumables in it.

when you’re pierced delay is set at .5 seconds in your post settings in Fusion 360 then in fire control dial it back to about 74% this will help with the initial Pierce mark.

The only reason I can see for the mark at the end would be the torch with a slight lag shutting down.

Also line cutting is fast as possible while still cutting through properly is a good idea.

Ok thanks for the help, I will do that on my next cuts. Also I will get some more consumables, do I need to replace all 4 parts or just the nozzle and electrode? I wasn’t sure how long they should last I made about a dozen large things and 60ish small parts. do I dare ask where the best place is to buy the consumables?