We have heard a few people having one or both of the following symptoms:

- Randomly, the torch will drive down for IHS, but never reach the plate before raising up to fire the torch.

- Randomly, the torch will drive down for IHS at an extremely slow rate. It touches down on the plate as normal but takes much more time to get there.

Both of these symptoms are caused by one thing: the IHS switch is being triggered before the torch reaches the plate. Recall that an IHS event involves the following sequence of events:

- The torch rapids down to the plate at a rapid rate, triggering the IHS switch

- The torch rapids up a small amount (~1/8") which untriggers the switch.

- The torch SLOWLY feeds down to the surface of the plate, triggering the IHS switch a second time. At this point, the Z position is recorded.

- The torch rapids up to pierce height, fires, and then rapids to cut height before motion begins.

Now lets discuss the ways that the IHS switch can be triggered even without touching the plate. The IHS switch is a normally closed switch and the weight of the torch and slide assembly are what keeps it closed (along with a 1/2 pound spring which offers further switch closing force). There are 3 primary ways that the switch can be opened and triggered:

- the torch touches the plate and unloads the switch (GOOD!!)

- There is insufficient slack on the torch cable. When the torch drives down the tension on the cable pulls up on the torch which unloads the switch.

- Excessive preload on the V groove ball bearings causes excessive friction with respect to the slide moving up an down.

If you are facing this problem, the first and easiest thing to do is to make sure you have sufficient slack in your torch cable. Try to provide the most slack possible.

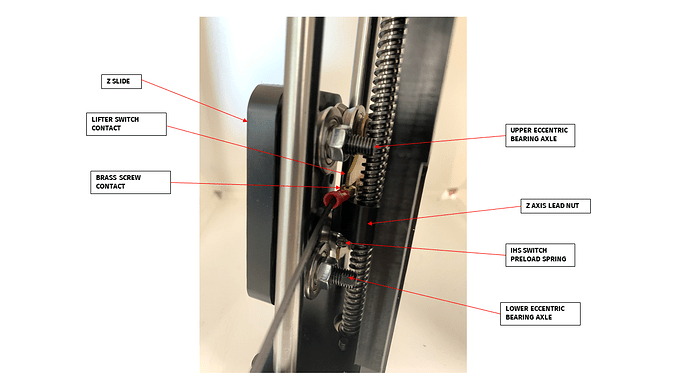

If that doesn’t fix the issue then you will need to adjust the preload on the V groove bearings. In the image below, you can see that there are two eccentric axles with which preload adjustments are made. Using a 5mm wrench, turn each counterclockwise to slightly reduce the preload. Be careful not to reduce it so much as to introduce excessive freeplay. The goal is to make certain the slide can move up and down freely so that the switch stays closed at all times when the torch is not touching the plate.