Yep, I am definitely having this issue. I was planning on mounting the Hypertherm under the table on a shelf, similar to Swizcores setup. After reading this I feel I will definitely need to cut out the excess cable on my CPC connection, and possibly make a shorter ground lead as well? The table and electronics enclosure are just outside there picture. THC is hooked up but Hypertherm obviously is not at this point. Let me know if you have any other ideas than what I mentioned above and the noise suppressors.

I suspect I had this issue for the first time last night, but it was at the end of a program. Never got a “program complete” message. The program stopped where I expected it to, torch turned off, control software froze, then a few minutes later recovered and I was able to move the machine again with the jog controls.

Will keep an eye on it and report back.

I don’t know if this has any effect or not but I want to clarify that I am running a self-made 20’ CPC cable that is spooled and hanging behind my 45XP from the rear table frame along with the extra torch and grounding leads. I TIG welded a flange to the bottom of my water table closest to electronics that I use for attaching my grounding clamp.

As shown in my setup photos, my 45XP is sitting with the water tank between it and the electronics enclosure. I’m not sure if this works as a buffer between any could be electronic interference that would otherwise be happening.

I have not had any of the interference issues others have reported. The issues I did have were due to using Lead-outs with THC and also SMART voltage on THC was not jiving with 16g and my 45XP. Switching to 128v manually in THC rectified the issue.

Experienced something strange today. While cutting whenever my compressor would kick on I would lose arc and get a popup and have to “run from here”. Happened every time the compressor would kick on while cutting. Messed up one of my cuts

Low pressure alarm on the cutter, as in is the arc actually turning off?

POWERMAX 45 ARC-OUT WHEN COMPRESSOR KICKS IN

TL;DR

The wiring for the compressor/plasma was inadequate and the voltage drop caused by the compressor kicking on caused the plasma to lose arc.

But I would also check your pressure like suggested above.

Will Firecontrol shut down when cutting a perforated material? THC probably isn’t going to like expanded metal and curious to know if Firecontrol will keep the torch lit. No IHS, THC and run the cutter in rapid restart?

If your plasma cutter has the ability to keep the pilot arc on after crossing kerf or perforations, then it should work with THC although we have not tested it. It will certainly work with IHS.

My Hypertherm Powermax 45 has a setting for that.

The cutter has auto restart and also latch modes. I’m tracking Firecontrol wanting to keep voltage at +/- 1.5v. If the THC is on it will sense pilot arc voltage in openings and transfer arc voltage when actually cutting. I was thinking this delta would have Firecontrol trying to adjust when it really didn’t need to.

I need to get the table to figure this mess out. How about loosen the OT purse strings, crack the whip or offer employee’s exciting vacation packages to exotic destinations to move them things out!

That’s interesting … my Miller 625ex has a feature for expanded metal that keeps the cut going…but it’s not adjustable on the plasma unit that I know of. I’ll have to experiment with some expanded metal and thc / ihs when I get my table in.

No possibility of the torch nozzle dropping between the strands? I am stuck thinking the nozzle could drop between the strands and IHS sets a false zero on the Z axis. Not doubting you… just must be missing something. The example above is 1 1/2" standard XM.

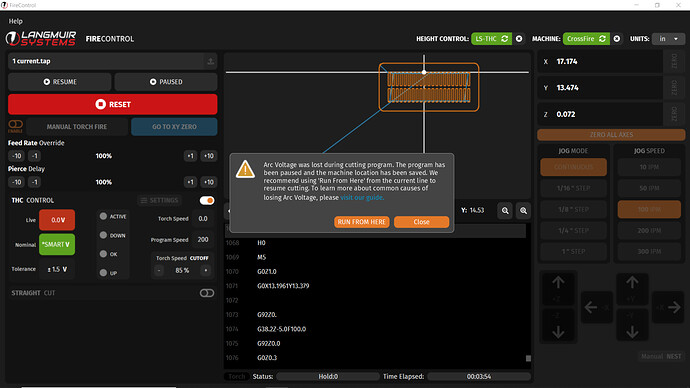

Pretty sure I had this issue today, but it only seems to affect the machine if the THC is enabled in FireControl.

Cutting along just fine, then THC powers the Z up until the torch is a ways above the material and just gouging the surface. Stopped the machine in FireControl, and the software froze. Re-zeroed after restarting FireControl and recut the whole program with the THC off, no problem, and no moving the cables.

Is this a symptom of the issue?

Problem, and the same height that the THC powered the torch up to, before I was able to stop the machine:

Point at which it froze:

If one of the Langmuir guys @langmuir-mike or @langmuir-daniel can confirm that this is a noise problem, and not something else, that would be awesome.

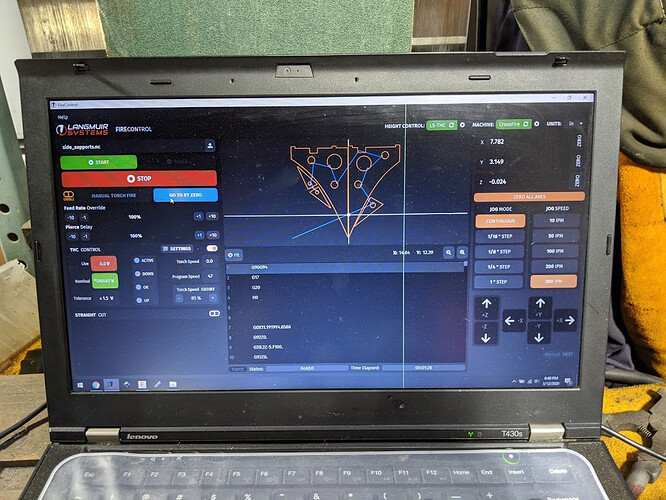

Hypertherm Powermax 45XP

45a, 48 or 50ipm (can’t remember)

0.25" mild steel

NC file:

side_supports.nc (7.8 KB)

Hi @moonshinefabworks we’re very confidant that what you are seeing is the noise problem that we’ve been discussing above. If you scroll up you can see my update to this thread today where we mentioned that as a precaution we are going to send out a snap-on ferrite choke to every CrossFire PRO owner that already has received their Box 2 so that they can solve this issue for good. We are going to start shipping these out early next week via USPS. In the meantime, the easiest way to prevent it for your setup is to move your plasma cutter away from the electronics enclosure as far as you can and also unloop any cables that you have including the work clamp and torch cable (loops in these cables can magnify the noise).

I know this doesn’t have anything to do with this category, but where did you get that rubber looking spark guard? And how long do they last.

Badass! Thank you for confirming! That’s very generous of you and your company.

It’s just a collapsible silicone funnel, cut to fit the torch. Makes a big difference, and cost $2.50 with tax at ace hardware. No clue how long it’ll last, but it’s cheap enough I don’t really care!

Thanks a lot. I seen these on amazon pretty cheap for a qty of 4.

What did they do just slide it up and it stays in place.