I’ve always had really good support from Everlast but it could be because I’m an affiliate? Not sure if that has anything to do with it or if I’ve just just been fortunate.

I’m using 50:1 through the CNC port and no issues. Maybe because I use double-shielded cable with proper shield draining? Who knows.

I even added ferrites to several of the board leads on the inside. Braided tinned copper over the USB cable(with soldered drain to grnd). Replaced ALL the wires on the inside with shielded cables. Swapped the DB9 pins for aviation terminals.

I don’t know why you guys have issues using the CNC port on the 82i but for me, it is working just fine.

That great to hear. I am glad it has worked for you.

@graeinc Welcome to the forum

I’m curious, what made you decide to dive into all those modifications without really understanding what was causing issues for others? Also, would you consider sharing a new walkthrough topic on the Forum about your solution? It could be really helpful for others facing similar challenges.

@langmuir-aksel can you please open up new user @graeinc 's ability to share content.

I just bumped @graeinc by one trust level, should be good to go!

I currently have the crossfire pro hooked up to hypertherm 45xp using cnc port…so when switching over to my new everlast 82i like shown in the pics, do I

1)unplug cnc cable from hypertherm

2)connect red and black wire to front of everlast as shown

and then that is all?

It seems that if I don’t plug a cnc cable between the back of my everlast and into the langmuir brains box (the larger box on the side of the crossfire pro table that has all the serial connections etc.) then I would be loosing THC and then nothing is also plugged into the the torch off/on plug on the brains box either? I am wondering if these pics just show part of the process and not the complete setup? Thank you!

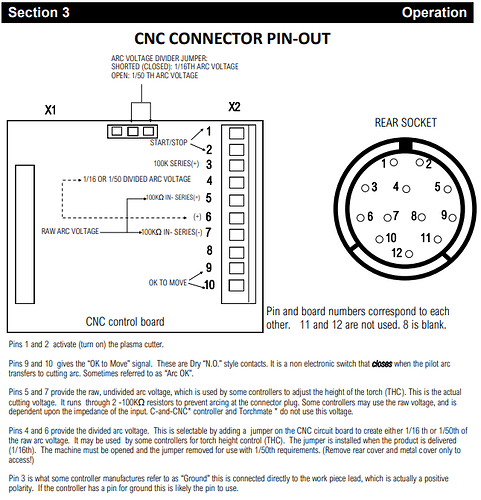

Still need pins 1 and 2 on the CNC plug to work the torch switch.

Since my everlast did not come with a cnc cable…do i just cut the end off of the wire coming from my langmuir brains box and the torch on/off cable and then hard wire it to the cnc connector plug for the everlast?

Pin 1 and 2 have no polarity just a switch.

I apologize but i do not understand what to hook in the 1 and 2 pin. On the back of the langmuir brains box i do have a cable coming out the back of it labeled as on/off but on the end of that cable is a cnc connector that plugs into my hypertherm…but that connector will not fit the cnc port plug on my everlast…so my question is how do i plug in that on/off switch into the cnc port on my everlast?

Did the Everlast come with a CNC port on the back? If it did there should be a blank plug that was supplied. The wire that goes to the torch on off plug on the control box will need to be soldered to pins 1 and 2.

That wire that you are holding. The other end gets connected to the pins in the diagram. It doesn’t matter which wire just the two.

Yes the Everlast did come with a blank CNC plug…and that was my question, so I will be cutting the end off of the on/off wire from the control box and then soldering it to 1 and 2 pin on the Everlast provided CNC plug. Then run the red and black wires to the box and front of Everlast cables as shown in the pics and I should be good to go?

Happy cutting my brother ![]() I got to Ask why are you going from a Hypertherm to an Everlast? Like trading in your Mercedes for a Ford.

I got to Ask why are you going from a Hypertherm to an Everlast? Like trading in your Mercedes for a Ford.

My hypertherm is 45xp and Everlast is 82i…I can cut 3/4" really nice with new consumables but \would like to be able to cut 1" - 1.5" and was thinking I should be able to do that with the Everlast since it is near twice the amount of amps? Your thoughts?

My 102i can do it. But I don’t have it connected to my table. 1 inch is the thickest I have attempted.

The 11 IPM will play hell with your water tray.

Remember to fill it all the way up. I even go as far as laying a 1/4 steel plate under the water on the bottom. The 102i cut a manhole cover in half one time with the hand torch. It was 1-1/4 around the edges.

Yes sir I do that as well…I have a piece of metal under the cut path. But do you think the Everlast will cut better than the Hypertherm for the 1.5" ? I don’t want to go through all the cutover trouble of swapping machines if it won’t be beneficial.

Anything over 3/4 of an inch will put you on the duty cycle roulette wheel. Small parts, maybe. Anything over several minutes, and it will show its ugly face. 1.5 is out of the question, in my opinion.

@wferguson - I kind of did the same as you.

Hypertherm 45, needed to cut 1 inch.

I picked up a used Hypertherm 1650 (100a) on ebay. The everlast 82 might do it. Going to be closer to 5 ipm on your cut speed. You will trash the water pain without a buffer.

Don’t clean it, leave all the slag in the bottom, or the buffer plate. 1/8 " minimum, and you will want a water gap between the buffer and the water pan.

I have done A LOT of thick metal cutting, You are in for a ride.

Fast Speed = taper.

Bad cut height = taper

Worn consumables = taper

One little hiccup (thc, air supply…) = taper

Taper = +/- 1/4 inch. Ugly.

Get a hold of some scrap plate that you can practice on. There is no jumping from 1/4" and sign making to whippibg out parts in 1" plate. master a straight line first, then work on circles.

Edge start, or plot and predrill with a .100" hole where the cut will start.

Trying to pierce anything over 5/8" = trashed shield, retaining cup and other parts.

Thank yall for the responses. I feel talked out of even using the everlast on this table like the squeeze isnt worth the juice. Even if thebEverlast could cut the 1" it seems that it would cause issues with my water table. Guess im just gonna have to wait until i can upgrade to the XR or either purchase a cnc laser cutter.