Interesting, I wonder how it ruined the torch. I haven’t seen any negative posts on plasmaspider about it, but it’s also sold through there.

Why not just spec a “hole” in the design and then fire the torch with a very short pierce delay? It won’t pierce but it will mark and then you’ve got your stuff location. If you’re using Sheetcam the pierce delay setting goes with the tool definition so you can create a marking tool profile and use it just for those “cuts”.

I’ve got the pro setup and an easyscriber in the torch. I’m not seeing an option in fusion 360 to disable IHS and put in a Z movement, or Z position (or z zero) to get the necessary preload. I’m new to this, and have zero G code knowledge other than what google tells me.

Any practical ideas on how to get this to work? Here’s a sample NC file we can use to test with. The changes we make here I’ll try with others I’ve got and share the results.

logo_background.nc (1.6 KB)

P.S. Super fricking nice to not have to remove the machine torch to change consumables (or put in easyscriber) with machine torch mount.

Here’s a link to the settings for SheetCAM

https://www.plasmaspider.com/viewtopic.php?f=172&t=28847

Might help you. I could try to run those settings through SheetCAM with the Pro post if you provide a dxf file, then I can send you the resulting gcode file.

also I take it you have read: https://theeasyscriber.com/userguide.html

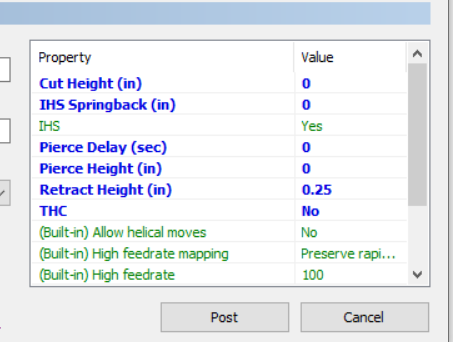

On edit, according to the user guide it doesn’t look like you have to disable IHS. So you can leave that on.

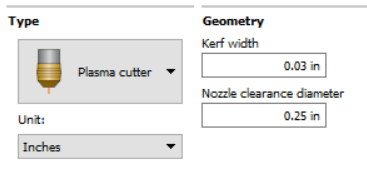

Did you define a new tool in Fusion for the easyscriber?

It seems I didn’t articulate the point I was trying to make properly. There’s no way I can see to disable the Crossfire PRO’s IHS in software (fusion 360), or in FireControl that I have found. No matter what tool is configured, IHS will always touch off when the scriber contacts the material. This is Z zero. Our cutting height is Z0 + whatever is defined in the tool in cam. With this, we’d need to make a negative cutting height to get the pro control software to power down below what it believes is the material height to preload the scriber. The “problem” is the IHS. Does that make more sense?

Looking at sheetcam, there is a 1/4" cut height defined in the easyscriber tool. That must mean that the control software that is being used on zeroes off of the material height with the scriber compressed. If it zeroed when the tip of the scriber touched the material, then came up .25", then it’d be the exact problem I’ve got now.

If you created a new tool, you would have to create a negative cutting height to “defeat” the IHS’s retract measure, correct? That’s effectively crashing the machine, although in reality you’re preloading the tip.

Will the IHS not allow you to move if the normally closed IHS switch is open when you attempt to follow a tool path?

If I’m still not articulating my point correctly, I’ll build the tool in sheetcam and try to scribe something tonight. I don’t believe it’ll work because of the IHS, as articulated above.

Exactly. If Sheetcam allows a negative value. G-Code does but the question is if Sheetcam will allow it for plasma operations and if the Langmuir control box & THC module will as well. I can see where they might let it but also where a careful programmer might have put in an edit to make sure no one crashed it not thinking about this case.

We’d need to try Sheetcam (unfortunately I’m traveling on business this week) and if it did allow it, then try the Crossfire. If both do, we’d still want to let @langmuir-daniel know so they don’t later “fix” it if they didn’t explicitly decide to allow negative heights and then someone decides to prevent it.

But I think you’re onto the how we’d need to do it

On the right path I guess! Going to try it in fusion 360 first, as I need more practice with it, and I see myself using Fusion 360 primarily moving forward.

If it works, I’ll make a video. Still don’t know if FireControl will allow machine movement with the IHS open, but I guess we’ll find out.

As an aside, I was thinking there was some option to disable IHS in software because of this quote, but if there isn’t (aside from editing the gcode directly) then all we’ve got is a negative cutting height with the tool.

Daniel, do you know how to achieve this?

If we need to disable it because we can’t have negative values for height, we could change the post-processor to inject the IHS disable code so we don’t need to manually change the G-Code. Several of us have created custom post-processors so it’s not scary ![]() but we’ll just need the code that tells the Crossfire to turn off IHS.

but we’ll just need the code that tells the Crossfire to turn off IHS.

Cool! I can do that/figure it out if need be. Hoping there’s a smoother solution though!

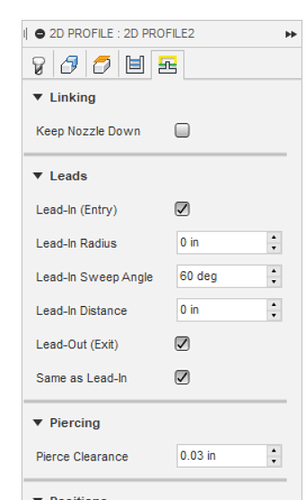

Would the keep nozzle down check box in Fusion keep the head at zero? I don’t have pro assembled to test it.

It should (if Langmuir’s post-processor & control box allow) but u haven’t tested it. It’ll be so much easier to get answers to some of these things when I get my machine up & running…pesky work getting in the way of Crossfire time ![]()

Zero is not deep enough. Zero is the tip of the easyscriber touching the surface of the metal with no preload. We need the PRO’s IHS interpretation of zero, -Z .250" to preload the easyscriber.

Might want to program your easyscriber drawings as mill paths in Fusion. that should let you set your Z.

That’s an idea too. Just need to know what the Langmuir control box would do with that G-Code.

OK guys, I have it figured. I’m working on a prototype right now. Very easy modification. Here’s a short videos of the Pro using the EasyScriber.

That’s awesome. Been thinking I would try to find a way to fit the easyscriber in my ptm60 torch

I was skeptical because I was told on a Facebook page by several people that it is bad for the machine torch. I was able to buy a spare for 100 bucks so my easy scriber will be here any day. What settings did you use?

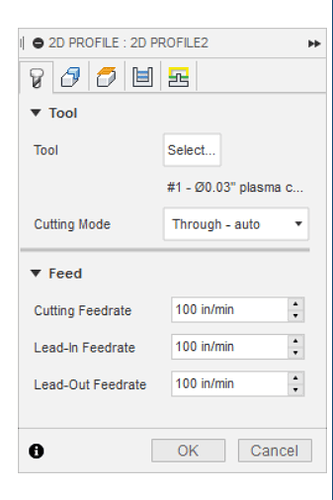

No modification is need (I got confuse with another project that I’m working). All you need is to enter the below settings and tool setup.

Let me know if that help you!!!

Nice work. Didn’t realize you could modify those values in the post-processor, but I guess I should have thought of that.

Thanks for posting your settings!!

EDIT: Question, why did you retain lead out and lead in? I’d assume you would remove those, as there’s no cutting happening.