hey all, wondering if anyone has cut 3/8in metal. Wondering if anyone could share the settings they used for post process. Thanks!

Yes, I have.

To answer your question we need more information.

What plasma cutter are you using?

What consumables are you using with that plasma cutter?

How big of a project is it ? Feet of cutting and pierces?

This may determine if you need a pause for during the program or not to till deal with the duty cycle of your equipment.

I think there is a thread somewhere on here started by @CrazyCasey with over 800 posts with “trouble cutting 3/8”…”in the title. You might try reviewing that thread and seeing what you can glean…But I wouldn’t . ![]()

![]()

I have cut 1/2 with a PW CUT60. I used the book settings.

@Knick and @Phillipw have been discussing cutting 1/2 in another thread.

I know you are asking about 3/8 but I think you can find good information in those threads.

Like @TinWhisperer said we need to know which cutter you are using as Settings will vary from machine to machine.

Any settings shared will need some verification through testing.

I don’t know how much help my thread would be to you, but I’ll give you two pieces of universal advice for thick material that you may or may not be aware of.

-

On thick stuff, your cut height is even more important. If you’re post-processing in Fusion 360 you probably want to set IHS spring-back to at or near 0, and you will also have 0.020” of “backlash” movement added automatically that a newer Langmuir machine likely doesn’t need. You’ll need to measure to know where you’re actually at.

-

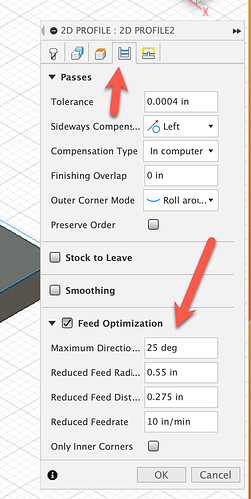

You want to slow down your tighter geometry; in Fusion 360 they call it feed rate optimization. Set the speed at 50-60% of your primary speed.

Beyond that, what everybody else said. ![]()

Those are just the things that weren’t made readily apparent for a beginner, in the stuff I read.

Good luck!

Casey, Did you get your control box yet? Just wondering? Saw the news the other day with 4 ft of snow your way.

Only about a foot where we are, but all the surrounding areas got dumped on heavy, and it’s enough that NO packages are moving. Just my luck, I guess.

Thanks for your reply. I don’t see the feed rate optimization setting. Can you also explain where to set the IPM in Fusion 360? Does the IPM you set there override the IPM that is set in FireControl? Thank you!!!

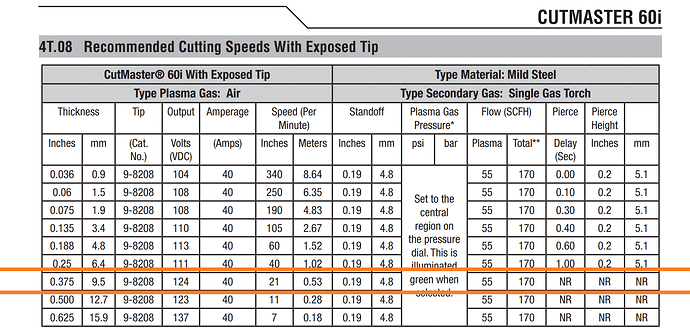

Thanks for the reply, I am using a Thermal Dynamics Cutmaster 60i. The project is 7in x 7in. I will post my fusion 360 file below. Thank you!!!

Thanks all for the replies. I attached my Fusion 360 file, I really need advice on the pierce height, springback, and pretty much all the settings used haha. Also looking for help setting the IPM. I read that an IPM of 15-18 is good for 3/8in cuts. Thank you all!!

jay hook v3.f3d (126.7 KB)

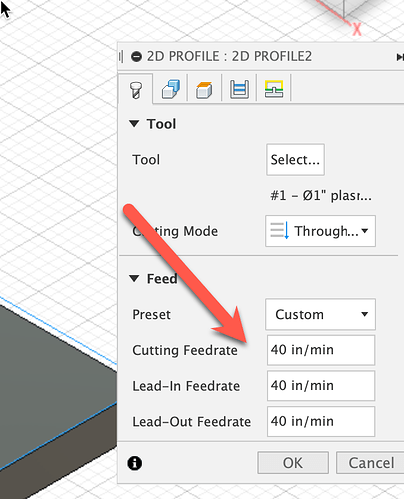

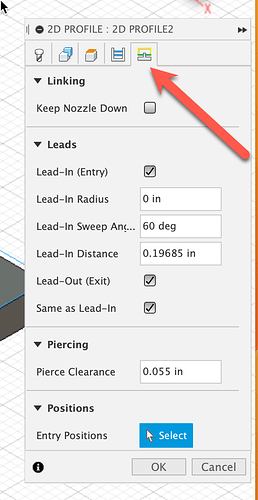

Do you have a cut chart for plasma cutter? A manual perhaps? Here are the places in Fusion you set feed rate, Fedd rate optimization and pierce height. Your pierce height looks very low in this file. .055 is closer to a cut height than a pierce height. What I seem to see is around .15 for pierce height on a lot of cutters but your manual should tell you that stuff.

FYI - Pierce clearance is not pierce height. It adds the value to the lead in / out. I recommend 0.

Pierce height & delay as well as cut height will all be located in post properties when you post process.

Manual

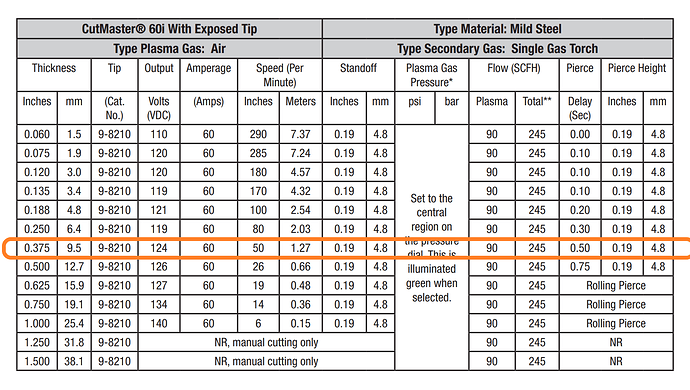

Here are a couple excerpts from the manual 53-54(4T-9 & 4T-10)

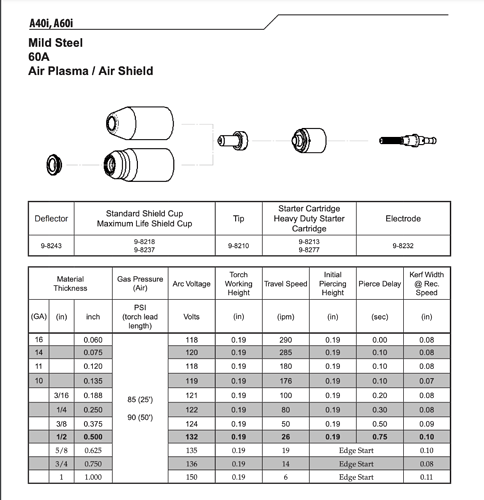

the 40 amp unshielded chart

the 60 amp unshielded chart

Some important notes.

ESAB has very high cutting heights (0.19")similar to the Hypertherm SYNC

In the 40amp chart pierce delay and height are NR this mean you sure only edge start it at this amperage so use the 60 amp chart.

The cut and pierce heights are the same height (.19") again similar to the new Hypertherm SYNC consumables.

Also a Different tip ( nozzle) is used for either 40 amps(part no 9-8208) or 60 amps (part no 9-8210)

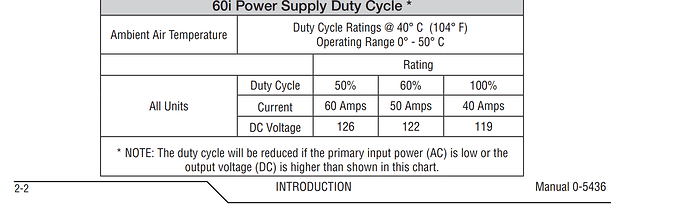

Here is a look at the duty cycle page 18 (2-2)

@ 60 amps you get 5 minutes of cut time for every ten, so adding a pause or pausing maybe in order

Use the information for the 60 amp charts to get you started.

The kerf width information maybe in the manual too somewhere?

thanks for sending. The manual says for 3/8 the pierce height should be .19

the manual can be found here: https://www.thermal-dynamics.com/thermal-dynamics/shared/content/requestliterature/en/aseriesairplasmasystems/upload/0-5466-manual.pdf

Can you help show me where to set the IPM? I have seen people on the forum says for 3/8 to set the IPM to 15 but the manual says 50

ok thanks I will set the pierce height to .19 and pierce clearance to 0

Thanks for sending. I noticed in this other version of the manual that the kerf width is 0.09in. Do you know where to set that in fusion? Also where to set the IPM in fusion? manual is recommending 50. Others on the forum mentioned around 15.

Can you also mention how to add a pause? Thanks!

The kerf is set in the tool setting in the tool library of fusion. I already sent you a screenshot above that shows you where to set IPM in the 2D cut profile, first tab. I don’t think you can set pauses in Fusion I think you need to edit the G-code for that. You can pause it manuallly in Firecontrol. I would keep it simple until you have the basics down.

UPDATE: as @TinWhisperer points out you can in fact add it to the g code in Fusion, I stand corrected!

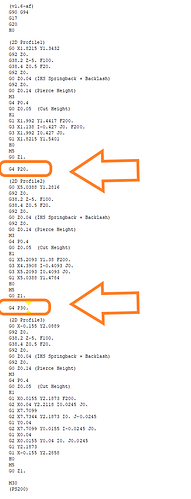

You can. it appears to make proper code but i have not run an actually program doing this way.

Check this out

6:30am mst

+1 to this

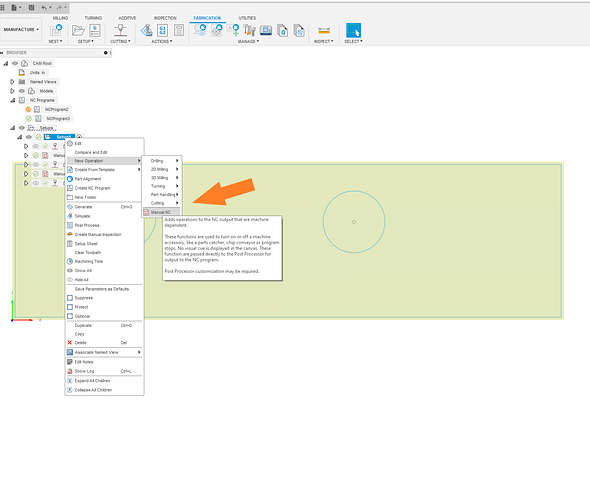

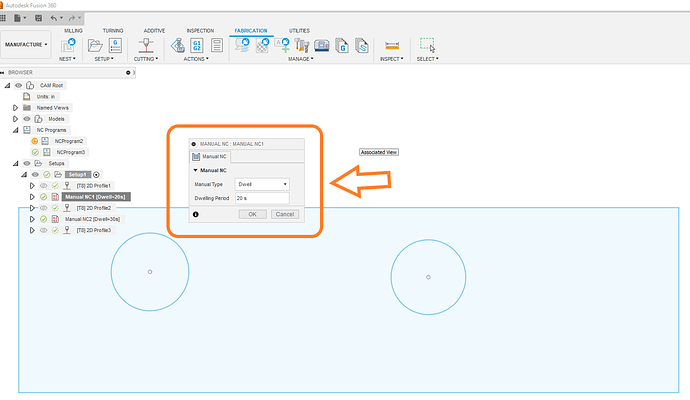

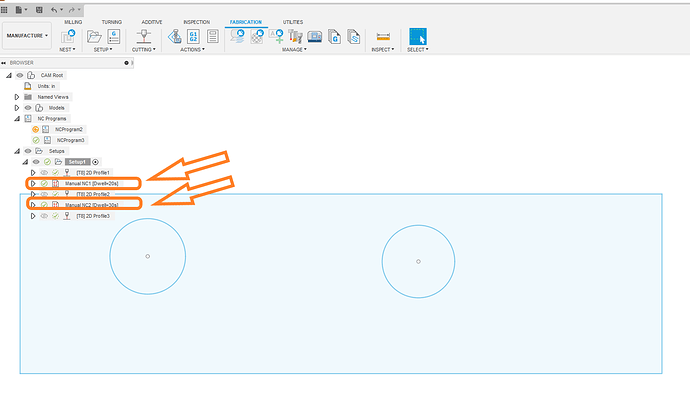

here are some screen shots of where to find and see the pauses or “dwell” in CNC talk.

Right click on the setup in the browser bar > new operation>manual NC then select the dwell option and write in your delay in seconds

The other reason I personally don’t end up needing pauses is that I run a PowerMax 85 so I have a really decent duty cycle.

@TinWhisperer Just watched the video, I did not know that ws there! Thanks for the video and pointing it out!

Great to use when a potential tip up issue can threaten a cut. I am going to try it and see if the simulation shows the pause, then start using this method. I’ve been trying to jump in there with a pole magnet and snag tip ups.

BTW, that first time when you tried to enter 20 secs and it only showed 5 in GCode, wasn’t sure if you remembered initially you entered 5, then backspaced over it and entered 20. Seems like that “crappy F360” liked the first answer the best ![]()

Thems fightin’ words!!! ![]()