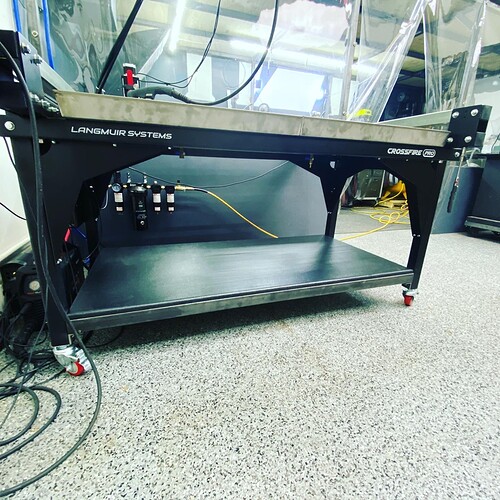

Just a week into getting my final box the Crossfire is up and running. Great piece of gear. Kudos to the Langmuir Team. Also I added a shelf & casters to the stand. I plan on doing a water bin underneath with a filter and such.

Nice!! Did the studs on those casters thread directly into the factory Langmuir holes?

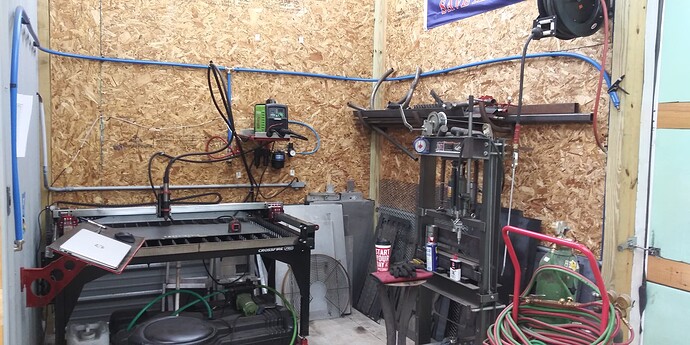

So what I can see in one of your pictures is that, for your compressed air it looks like you have a water seperator, then a dryer, then two more water seperators. is this correct?

Yes that is exactly right. Nice and dry air going into the RazorWeld.

I’m very interested in more information on those casters. Do you have a make/model for us? Thanks!

Do you mind sharing what those components are?

Sure, I bought this setup from USA Weld https://www.usaweld.com/Max-Dry-for-Plasma-Cutters-p/25310-2.htm

Yes, these fit into the hardware perfectly and they are really solid. https://amzn.to/31DvRhc

Awesome! Thank you so much!

Thanks! I’m going to give that a shot as well.

I read elsewhere on the forum here that attaching a shelf under the plasma table to the actual legs could shift the whole table out of square. Did you have any issues with squareness after installing the shelf, or potentially after loading the shelf up with items? Thanks for responding… This is my first time posting on the forum

I have a shelf underneath. Actually version 2 because my first version…. May not have been perfectly square. If you do it carefully, you can keep it square. But if I could do it all over again, I’d build a platform for the table to sit on so I don’t weld or attach anything to the table itself.

Many have done this, but I don’t know where to find photos for you. Someone else might chime in.

I never did the shelf under. @toolboy did and had some issues with the table working its way out of square.

Here is what I did. The description and all the plasma cut parts are on fireshare.

I just finished my rolling base a couple weeks back… I designed it over a year ago… I am pretty slow. ![]() I have almost the entire thing modeled in Fusion down to the washer on top of the hockey puck. I was going to cut a custom one so I could cover more of the top of the puck… but ended up just using one off the shelf. I did the modeling as an exercise to learn assemblies and joints for a future project. I did a short video on the leveling casters. I am planning on posting the components on Fireshare. I just wanted to make sure everything worked before I did. Here are a couple of pics.

I have almost the entire thing modeled in Fusion down to the washer on top of the hockey puck. I was going to cut a custom one so I could cover more of the top of the puck… but ended up just using one off the shelf. I did the modeling as an exercise to learn assemblies and joints for a future project. I did a short video on the leveling casters. I am planning on posting the components on Fireshare. I just wanted to make sure everything worked before I did. Here are a couple of pics.

I plan to take some more pics once I get the table back together.

Components List:

(4) Base plate

(4) 3-1/4” L3x3x3/16 angle

(4)Caster mount plate

(8)Gusset plates

(4) 9” 3/4” T rod

(12) 3/4” hex nut

(4) 1/4 spring pins

(4) hockey pucks

(4) 3/4 flat washer

(4) 1/4x1-1/4 fender washer

(4) 1/4-20 x1/2” cap head screws

Frame Tubing… I used 14ga 3x2 and 2x2 tube because I have a bunch of rejected remnant from a local treadmill manufacturer… use whatever. If you want any dxfs of the cnc cut components, you are welcome to them.

I built a roller base to set my pro table on a few years back. The table levels to the base, the leveler bolts on table sit in square tubing at four corners so don’t slide off roller base.Table stays square.

What @72Pony and @rat196426 did is the way to go.

I’m not an expert on @toolboy but I thought his issues was from casters and the legs not being supported enough.

The setup that @rat196426 did was one of setups that was the inspiration for mine. He @Hellbent and @Wsidr1 were some of the first people I saw that made an actual rolling platform that the table just sits on. These threads have some good info in them.

Wheels on crossfire pro - Langmuir Systems Forum

Pimp My Pro- Mods and Addons - CrossFire ® PRO - Langmuir Systems Forum

Wow! This forum is fantastic. Id heard a lot of times that people are great at responding on here and I’m absolutely impressed. Thank you all for responding and sharing insights and links. I’ve never had an experience like this on any forum and I’m so happy I asked. I was going to screw a shelf to the legs with self tappers but after reading everything, I’m going to build the cart instead. You all may have just saved me from a bunch of headaches and disenchantment with my new LS Pro.

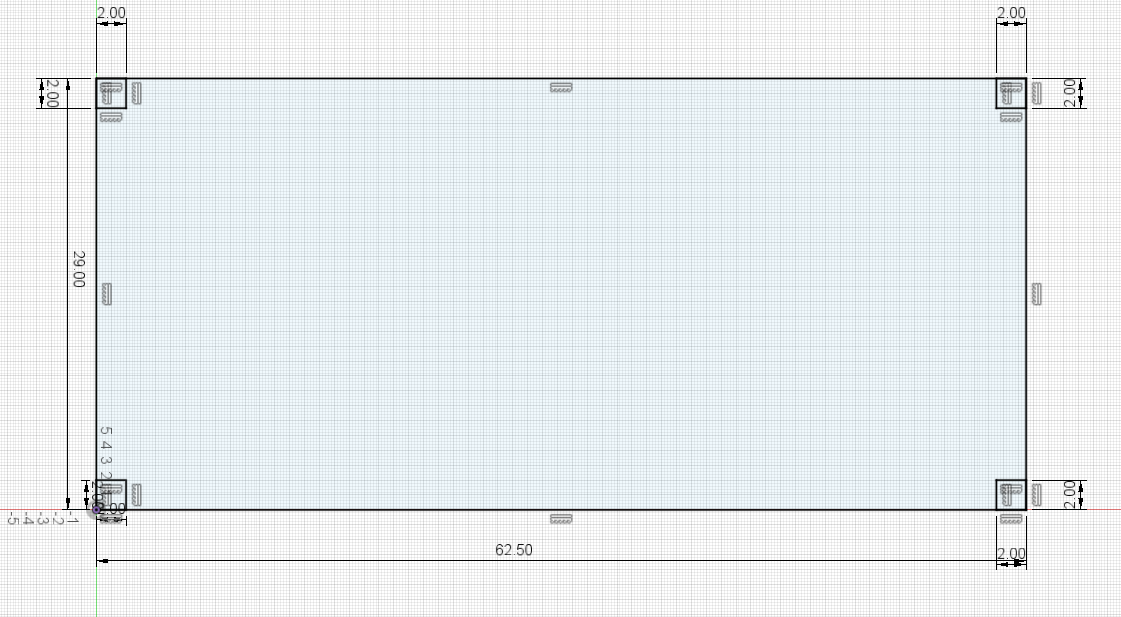

Does anyone have the dimensions of the table they put their CNC on?

I’m looking to get the dimensions of the legs and the spacing/distance between the legs so I can place them properly in a CAD design.

I don’t have the CNC built yet, so I can’t necessarily get dimensions first-hand.

Thank you,

Mike

If you are talking about the legs, here are the dimensions (+/- 1/4"), or at least that is the dimensions of how mine turned out. There are some design changes that may have been made in the last 3 years so I would consider waiting until your table is built. If you use my dimensions, you use them at your own risk.

Thank you so much, @ChelanJim .

I appreciate this!