What CAM are you using in Solidworks?

Just the built in Solidworks CAM

Ah, that’s what I was afraid of. I use SolidCAM, which is a 3rd party addon. I’m very familiar with it and can write post processors for it. Solidworks CAM I haven’t used at all. I’m going to install it and see if I can resolve your issue. I know how frustrating it can be to not be able to get any help. I can’t make any promises but I’ll give it a go and get back to you.

I ended up getting it to “work”. Just used a generic mill post processor. It wouldnt accept my zero orgin, so i ended up having to fake some stuff out to get it to work.

It worked but it for sure isnt as smooth as it should be

Unfortunately I will need the .src file used to create the MR-1 CAMworks post processor that SWCAM uses in order to change or just see if the long code option is enabled. The other option is I could just create a new post with it enabled but I don’t have any way to debug it. I would need to reinstall my Solidworks to enable the SWCAM package and that’s a tad beyond what I’m able to do at the moment.

The long term solution for everyone would be implementing the recognition of canned cycles. That is the ultimate/proper solution for everyone. Canned cycles were invented to be used by old controls that had to keep programs short and I’m surprised it wasn’t a base feature from the beginning.

If this is just not something you can put up with I’d be willing put in some more effort and see if I can get a working post for you. Just let me know. Would definitely be worth reaching out to tech support if you have it for a solution also. I for one keep leaning on converting mine to LinuxCNC every time I use it.

Dre,

I am having this same issue with the built in soliworks CAM MR-1 post processor and being unable to tell it to not output canned cycles. I am more than willing to put up with the longer programs. Have you made any progress on witting a post processor for solidworks CAM that disables the canned cycles output?

Hey, sorry for the delay.

I haven’t modified my SW to enable the SolidworksCAM module. Doing so will require I remove my current CAM software and i have a lot of data to backup to do so.

I do however have the Camworks post processor development tools required to create a post for SWCAM. I will create one tomorrow morning and post it here. Keep in mind that I won’t be able to do testing currently and I’m not at all familiar with the Camworks system so I will need your guys help if you run into any issues with it. I will at least be able to make changes.

Sounds awesome, I have some experience editing post processors but not with creating them form scratch so I might be able to help iron out any bugs once the initial post is written.

Thanks!

Here’s the link to the new topic regarding the SolidworksCAM/Camworks post.

Are you using cobalt drills or carbide? I drilled some 1/4” holes in 6061 .75” deep today with the cobalt stub drills Langmuir sells and used the reference guide. Used the peck with partial retract in fusion and with ref parameters of 1525 rpm, 4.5 IPM, .04 peck and .5” accumulated depth. For the first 1/2” was fine and drill had full retract after accumulation depth reached as set. then started peck for the final but drill packed solid on the final .25”. This happened in multiple holes. I am using dual misters with “kool mist 77 solution” instead of flood…not sure if that has effect. Anyway looking for suggestions!

Some people prefer mist sprayers. I have one installed on my Bridgeport. I have no trouble drilling aluminum with the Fusion 2240. I like the flood system on the MR1.

Are you using the Langmuir guide?

.250 hole uses 4500 spindle speed.

Cutting Parameters - Getting Started Reference Guide - Rev. 11_30_2022.pdf (71.7 KB) The number you gave are for steel/cast iron, softer ferrous metals. Not Non-Ferrous.

I use the Langmuir stub drill bits, and they have worked great. I believe that they are cobalt. Could be black and gold type. Not sure about them.

Yea…sorry I picked off the wrong numbers for the post to you…went back to verify in the CAM that I did use the non-ferrous numbers. So what is in

CAM is 4575 rpm, 6.75 IPM peck, .05 peck depth and .5 accumulation. I retracted after each peck 0.01”. As I mentioned the second peck cycle (after .5” accumulation was reached and there was full retract), the aluminum welded to the drill flutes.

Yes, those are the settings. 6061 is rarely gummy. You might want to spray some coolant from a spray bottle during the drill process. All the settings have worked for me.

Will try that…I use WD-40 on my Bridgeport when drilling aluminum and it seems good but I’m hand feeding and can adjust if I see chip sticking to drill!

With everything being the same. The flood coolant is the only difference.

I use KoolMist 77 on my machine with a Fog-Buster type coolant system. Are you doing full or partial retract on the peck? I have to do full retract when drilling deep holes to make sure that any chips are blown off of the cutting part of the flutes.

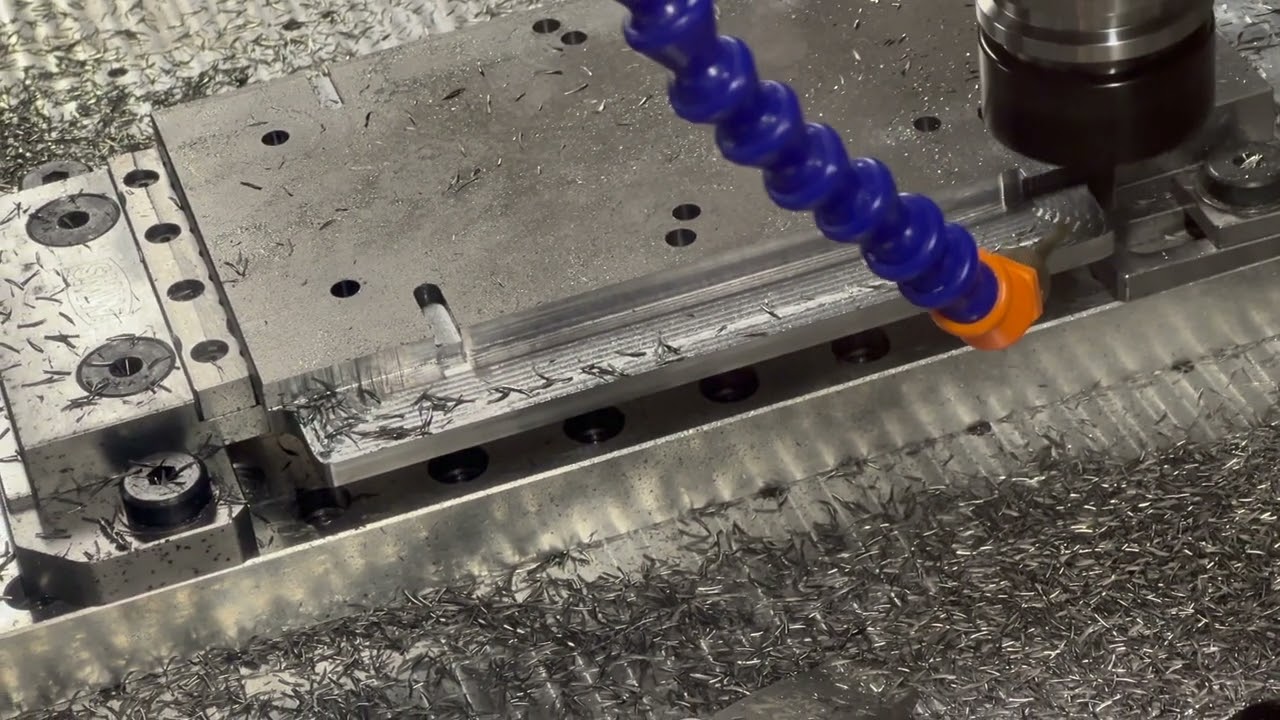

The start of this video shows a 3/16" hole being drilled 1/2" deep in steel and you can see the full retracts:

Aluminum is gummier, but I use a similar process, just higher RPMs and feed rates.

i do chip breaking with partial retract unless the hole is greater that the 3X dia as recommended in the “starting Parameters Ref Guide”

Langmuir sent this video on how to get long code from solidworks I did find however that when i post processed i had to remove any H codes and all the N line numbers and some of the beginning coordinate information. How to create drill cycle without canned cycle error.mp4 - Google Drive

See what i got for output originally and how i used chat GPT to delete N lines then modified the beginning lines. This code worked great for drilling in aluminum.

Fixed to work in cut control.txt (3.7 KB)

original output from other post processor.txt (5.8 KB)

Video is okay…after posting Milltutorial and then swapping post for MR-1 and reposting, it shortens to can cycle. Anyone have better input on how Langmuir made this work?