how do you measure torch air? I just watched the gauge on the front of the machine while its firing

I am not familiar with your model machine, but most machine have a torch air pressure Guage on front face of the machine and air setting regulator mode switch to set air pressure to torch itself or an internal regulator preset at factory (which can be adjusted) if you remove side panel on machine. Air supply pressure is separate from the torch setting pressure. Air supply from compressor to back of cutter is 110-120 psi. Hope this helps you.

Any luck with trouble shooting yet…?

HI, I ran into the torch rising issue this morning on my pro with THC. Very frustrating.

At first I thought it was my job settings, as I am still getting familiar with the software workflow. But then, after ruining a couple of cuts, I started poking around my wiring and turns out that the controller-side (low-voltage) connector on the THC high-voltage adapter box was barely-just-kinda-sorta plugged in to the box. Maybe I bumped it while moving the machine?

Anyway, I reseated the plug and then scotch taped it to the adapter box to hold it in. Then I re-ran my job and it completed without a torch rise. My THC voltage was hovering right around 103v - 105v. For this cut, I was running the RazorCut45 at 30A 80IPM on 16g sheet steel with super-dry refrigerated air.

Perhaps check that all your THC related connections are solid. Good luck and keep us updated.

So Langmuir got back to me and I did that voltage checks on the DIV box. Well during there testing, I did several 20" long cuts and it performed them perfectly without the DIV box connected and THC turned off. All my test came out fine so i believe I have a bad DIV box. To test this theory, I turned off THC and kept the DIV box disconnected and successfully cut 10 flanges without a hiccup.

my problem still persists. I replaced the plasma regulator today with a kobalt regulator thinking there could be something there but nothing. Also installed a desiccant dryer/filter. Even with THC turned off, I couldnt run for longer than 30 sec without misfire. I dont understand.

Work clamp on work piece (not on the table or slats), air set to 100psi to plasma cutter and plasma cutter set at 70psi flow, torch height set at .060".

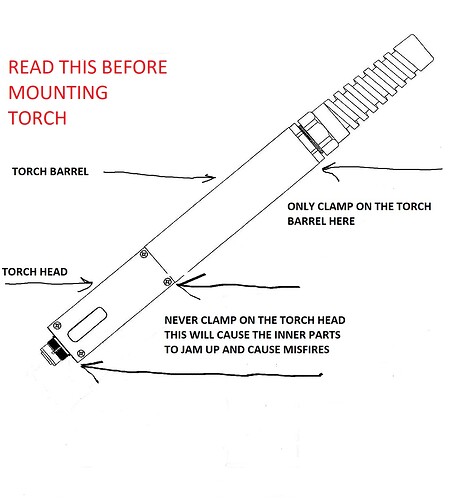

You also need to mount your torch correctly. The bottom clamp should never be on the torch head.

i always clamp to workpiece. Air pressure has been tested 60-100psi. Clamps were set as high as they could go after these problems initially started. The bottom clamp isnt even tight. I will test torch cutting height again but there was a really big discrepancy between programmed torch height and actual with the THC installed. I havent tested it with THC turned off. I will try that today.

Have you tried writing in voltage and not using smart voltage?

What state do you live in? Is the shop were the table Heated?

Also you need to uncoil all those wires you have and straighten them out all of them and the ones warped up on the plasma cutter. They will cause all kinds of RF signal interference.

Never run with loose cap. Your air pressure to torch is set to low set to 70-75 psi no more misfires. Never a misfire on mine for over 3 years now cap tight 75 psi. air to torch. You want 110-120 air pressure supply to back of plasma cutter.

im gonna do whatever it takes for this system not to misfire. I’m not sure how many times i have said I have tried pressure to the torch everywhere from 60-100psi and its makes no difference. If doing what i did fixes the problem, so be it. It sucks that its not right and thus there is some kind of flaw with my torch but its not like they are going to give me my money back for it.

Does the air coming out from torch seem to be enough pressure when it fires? Could have restriction… If torch rises to far from material, you will get a misfire as well. Have you cut with THC turned off just to see if misfire problem goes away? Process of illumination.

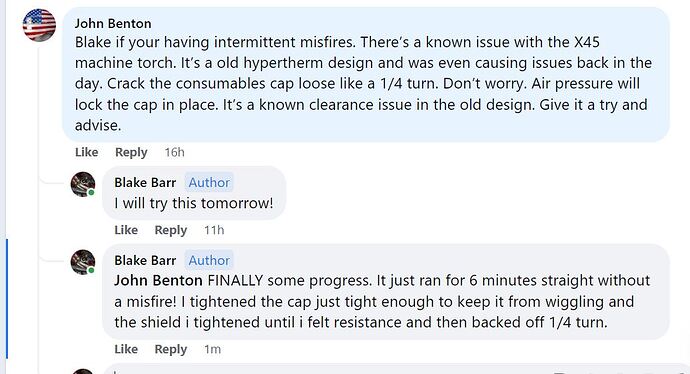

THC has been turned off. i dont understand how its related to pressure when I can make the torch misfire simply by finger tightening the consumable shield. With the shield tightened only to the point of feeling resistance, it will misfire within 20 sec of run time. When I crack it loose 1/4 turn from there, it ran a complete program for 6 minutes with no misfire. Something its never done before with all the other testing I have done. Regardless of pressure, regardless of consumable life, regardless how dry the air is, regardless if im using a wall powered laptop vs battery power, regardless if the wires are a tangled mess, regardless how close i have the cutter to the electronics box, regardless of torch position on the mount, regardless where the ground is (even though i always ground to material everytime i can); cracking the shield is the ONLY thing I have done which has consistently not given me a misfire. I’ve ran that program twice for 6 minutes. 12 minutes total without a misfire (cross my fingers). explain that aside from an issue with the torch itself.

I think you have found the problem. Maybe @mechanic416 can shed some light on what may be causing it.

i sure hope so. I have lost my butt on the work I’ve done with it so far

just guessing here i am not saying your air pressure isn’t right but with the cap loose it may not take as much air pressure or volume to blow the electrode back than if it is tight.

i am with you. got to do what you got to do … but also, with everyone else something isnt right because it isn’t meant to be uses with the retaining cup loose.

im with everyone in believing there is something wrong.

no doubt. that is just my opinion on why air pressure or volume of air could possibly make a difference. is there any chance you have the correct pressure but can’t keep up the volume?