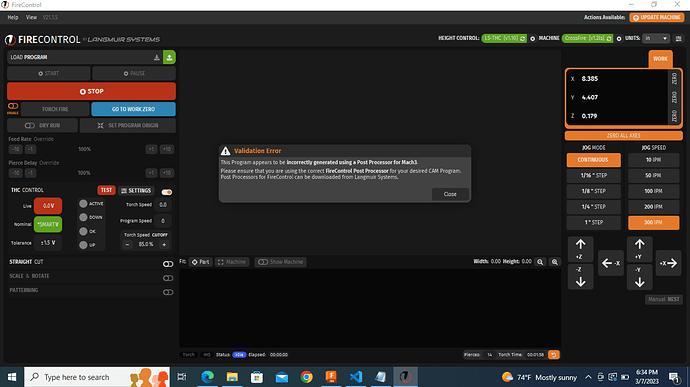

How do I get rid of mach3 posts no matter what software i use it only posts in mach3 which won’t run in firecontrol

Fusion 360 or SheetCAM?

If it’s Fusion in the very last menu before you make your G-Code the option to change your post processor is in the top left.

tried both no luck anyone in the western NY area for help I will pay for help

did you download and copy over the firecontrol postprocessors for either fusion or sheetcam?

Are you using the Mach3 post processor or are you just getting the error message in Firecontrol that says the file was post processed for Mach3? That message is just a generic message that means Firecontrol can’t read the file, but it doesn’t necessarily have anything to do with Mach3.

What program are you using to post process? Fusion or Sheetcam?

I am getting the Mach3 message you are talking about. how do i correct it. I have tried downloaded files and have created ones from scrach and get the same message.

any help would be great.

These things are much easier to diagnose if you can copy and paste some of the code from your cut files. Open a file with Notepad and copy and paste the code. A smaller cut file will allow you to post the whole code.

I’m not sure if the forum allows.nc or .tap files to be uploaded here, but that would work also.

(Test Plate)

N10 G90

N15 G20

(2D Profile1)

N20 M36 T1

(Through cutting)

N25 G0 X1.1158 Y5.1105

(TURN ON CUTTING)

N30 M7

(POINT-PIERCE)

N35 G4 F5.

N40 G1 X1.0692 Y5.199 F48

N45 G3 X0.9341 Y5.2408 I-0.0884 J-0.0467

N50 X1.1459 Y4.8392 I0.1059 J-0.2008 F12

N55 X0.9341 Y5.2408 I-0.1059 J0.2008

N60 X0.8586 Y5.1764 I0.1059 J-0.2008

N65 X0.8784 Y5.0364 I0.0799 J-0.0601 F48

N70 G1 X0.9583 Y4.9763

(TURN OFF CUTTING)

N75 M8

N80 G0 X3.5183 Y4.067

(TURN ON CUTTING)

N85 M7

(POINT-PIERCE)

N90 G4 F5.

N95 G1 Y4.167 F48

N100 G3 X3.4183 Y4.267 I-0.1

N105 G1 X2.37

N110 X2.14 F12

N115 G3 X1.813 Y3.94 J-0.327

N120 G1 Y2.37 F48

N125 Y2.14 F12

N130 G3 X2.14 Y1.813 I0.327

N135 G1 X3.71 F48

N140 X3.94 F12

N145 G3 X4.267 Y2.14 J0.327

N150 G1 Y3.71 F48

N155 Y3.94 F12

N160 G3 X3.94 Y4.267 I-0.327

N165 G1 X3.3183 F48

N170 G3 X3.2183 Y4.167 J-0.1

N175 G1 Y4.067

(TURN OFF CUTTING)

N180 M8

N185 G0 X5.1131 Y5.1134

(TURN ON CUTTING)

N190 M7

(POINT-PIERCE)

N195 G4 F5.

N200 G1 X5.0631 Y5.2 F48

N205 G3 X4.9265 Y5.2366 I-0.0866 J-0.05

N210 X5.1535 Y4.8434 I0.1135 J-0.1966 F12

N215 X4.9265 Y5.2366 I-0.1135 J0.1966

N220 X4.8535 Y5.1694 I0.1135 J-0.1966

N225 X4.8786 Y5.0302 I0.0822 J-0.057 F48

N230 G1 X4.9608 Y4.9732

(TURN OFF CUTTING)

N235 M8

N240 G0 X5.0901 Y1.1306

(TURN ON CUTTING)

N245 M7

(POINT-PIERCE)

N250 G4 F5.

N255 G1 X5.0183 Y1.2002 F48

N260 G3 X4.8769 Y1.1979 I-0.0695 J-0.0719

N265 X5.2031 Y0.8821 I0.1631 J-0.1579 F12

N270 X4.8769 Y1.1979 I-0.1631 J0.1579

N275 X4.8251 Y1.1132 I0.1631 J-0.1579

N280 X4.8875 Y0.9863 I0.0947 J-0.0323 F48

N285 G1 X4.9822 Y0.9541

(TURN OFF CUTTING)

N290 M8

N295 G0 X1.1131 Y1.1134

(TURN ON CUTTING)

N300 M7

(POINT-PIERCE)

N305 G4 F5.

N310 G1 X1.0631 Y1.2 F48

N315 G3 X0.9265 Y1.2366 I-0.0866 J-0.05

N320 X1.1535 Y0.8434 I0.1135 J-0.1966 F12

N325 X0.9265 Y1.2366 I-0.1135 J0.1966

N330 X0.8535 Y1.1694 I0.1135 J-0.1966

N335 X0.8786 Y1.0303 I0.0822 J-0.057 F48

N340 G1 X0.9608 Y0.9732

(TURN OFF CUTTING)

N345 M8

N350 G0 X5.913 Y3.4806

(TURN ON CUTTING)

N355 M7

(POINT-PIERCE)

N360 G4 F5.

N365 G1 X5.813 F48

N370 G3 X5.713 Y3.3806 J-0.1

N375 G1 Y2.37

N380 Y2.14 F12

N385 G3 X5.8765 Y1.8568 I0.327

N390 G2 X6.063 Y1.5338 I-0.1865 J-0.323

N395 G1 Y0.5124 F48

N400 G2 X5.5676 Y0.017 I-0.4954

N405 G1 X4.87

N410 X4.64 F12

N415 G2 X4.317 Y0.2035 J0.373

N420 G3 X4.0338 Y0.367 I-0.2832 J-0.1635

N425 G1 X2.2762 F48

N430 X2.0462 F12

N435 G3 X1.763 Y0.2035 J-0.327

N440 G2 X1.44 Y0.017 I-0.323 J0.1865

N445 G1 X0.5124 F48

N450 G2 X0.017 Y0.5124 J0.4954

N455 G1 Y1.3038

N460 Y1.5338 F12

N465 G2 X0.2035 Y1.8568 I0.373

N470 G3 X0.367 Y2.14 I-0.1635 J0.2832

N475 G1 Y3.71 F48

N480 Y3.94 F12

N485 G3 X0.2035 Y4.2232 I-0.327

N490 G2 X0.017 Y4.5462 I0.1865 J0.323

N495 G1 Y5.5676 F48

N500 G2 X0.5124 Y6.063 I0.4954

N505 G1 X1.3038

N510 X1.5338 F12

N515 G2 X1.8568 Y5.8765 J-0.373

N520 G3 X2.14 Y5.713 I0.2832 J0.1635

N525 G1 X3.71 F48

N530 X3.94 F12

N535 G3 X4.2232 Y5.8765 J0.327

N540 G2 X4.5462 Y6.063 I0.323 J-0.1865

N545 G1 X5.5676 F48

N550 G2 X6.063 Y5.5676 J-0.4954

N555 G1 Y4.7762

N560 Y4.5462 F12

N565 G2 X5.8765 Y4.2232 I-0.373

N570 G3 X5.713 Y3.94 I0.1635 J-0.2832

N575 G1 Y3.2806 F48

N580 G3 X5.813 Y3.1806 I0.1

N585 G1 X5.913

(TURN OFF CUTTING)

N590 M8

N595 M19

N600 M30

will this help

Yeah. That helps. That code is not even close to what is needed for Firecontrol. What are you using to create the code? Fusion or Sheetcam? Either way, you need to use the Firecontrol v1.6 post processor.

fusion 360

Ok. I don’t use Fusion, so I can’t help you with how to install the proper post processor. One of the fusion users, like @TinWhisperer can probably help you with that.

I just got this set up and have no clue what I am doing. I did cut one thing from the share files but nothing else works. I have tried every set up video I can find.

Have a look at the link in this thread. It’s for the mr1, but the process is the same for installing the Firecontrol v1.6 post processor.

@mwcpd131 I missed a PM from you about a week ago.

How are you doing with this issue?

Were you able to install the post processor?

Yes sir I was able to get the post processor working the only issue I’m having now is the THC when I have it on it starts cutting and as it goes it slowly raises up if I turn it off it cuts everything just fine I still have to learn my Heights and speeds to get everything correctly. I have not had time to research the THC to find out why it’s doing that if you have any information on it that would help greatly thank you

It’s your IHS triggering early?

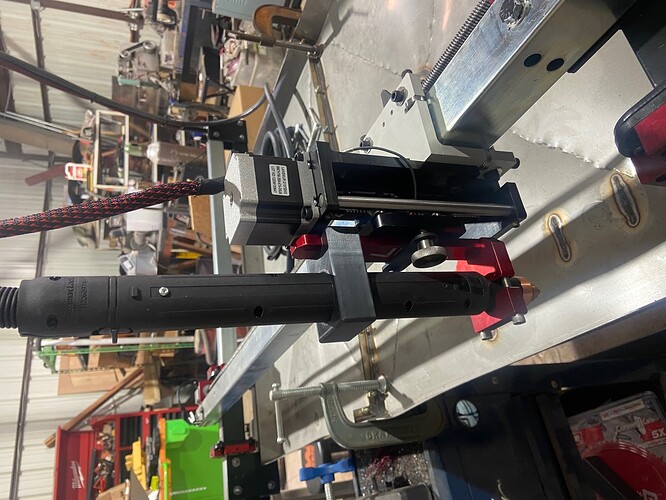

Could you post a picture of how your torch is mounted on your pro.

Sometimes there might be not enough clearance on the z axis depending on how you mounted the torch.

I’m Canadian so American phone calls are costly for me but if you want to talk on discord I’ll be back from work at 3:00 p.m. Pacific standard time today.

I would check the up and down motion of your z-axis and make sure it’s not triggering the IHS at the wrong time.

You can tell if the IHS switch is closed by looking to the bottom of fire control there is a box that will turn green once the IHS switch is closed. You can trigger this yourself by manually pushing up on the torch softly the same way the torch would push against the metal when touching off during the program.

It does give an error code that says the torch started to move before it fired sometimes. I will get some pics.

I have a video but it the forum will not allow that to upload. thank you again for your time.