How’s it! I got a crossfire pro with a razor weld cut 45. Can’t seem to get nice perfect circles. What’s the issue? Thanks!

You might take a look at this topic: Lead screw/travel problems, Circles aren’t circles, and I’m a noob

Many of us have had this problem at one time or another. Without all the detail,

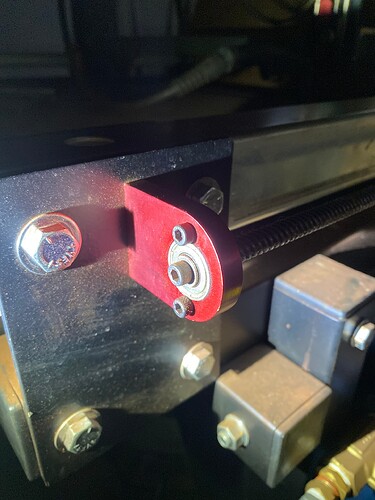

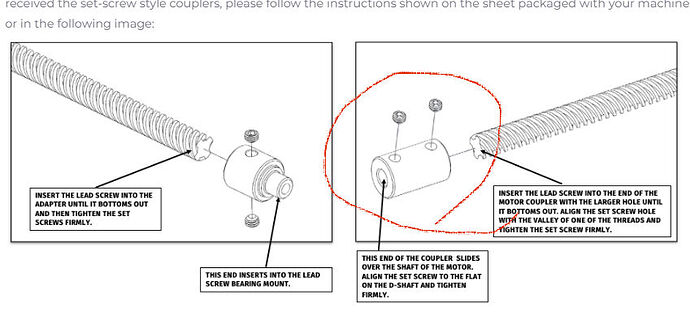

- I would first suspect that the couplers that hold the lead screws are not secure/tight enough.

- Do you notice any drag or hiccup with movement when you are moving the gantry on a slow setting like 50 ipm? If you do, perhaps the lead screws need some lubrication (mineral oil or silicone spray). If you use silicone spray wait for it to thoroughly dry before using the machine and project any electronic contacts from spray getting on them (limit switches, and z carriage if you have the THC.

Welcome to the Langmuir Forum.

It is usually the coupler that attaches the lead screw to the motor that is the problem. I have had the one on the dummy end come completely loose and the cut barely suffered from the situation.

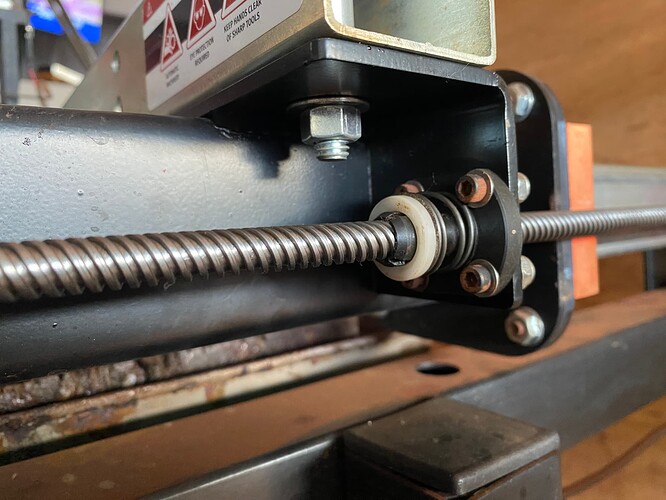

This coupler:

Check and see if there is any wiggle room when you try to twist the lead screw and hold the coupler steady. Likewise, can you wiggle the coupler on the shaft of the motor. Either side of that coupler could be causing the problem.

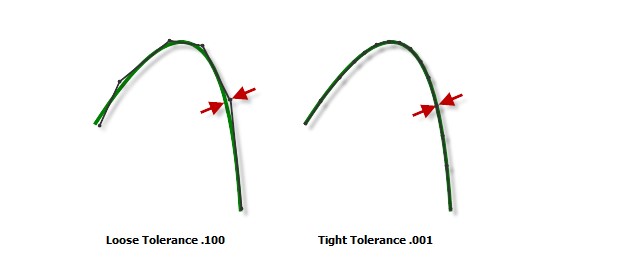

if no issues with table look at your Tolerance setting and check Smoothing when you’re generating toolpath. I don’t ever mess with it but I do remember this can make a big difference.

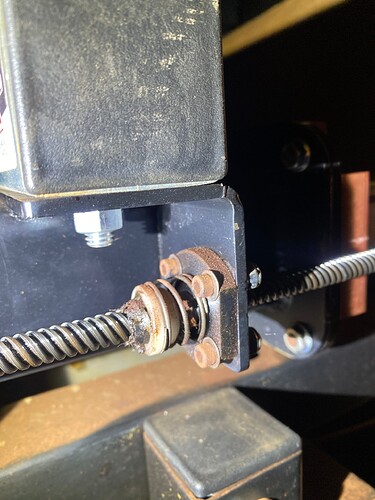

On closer inspection of your photos, there seems to be a fine dust/debris/sand on your table. If those lead screws ever had any lubrication on them before, this grit may be causing the issue with the threaded nylon bearing in the follows on the lead screw.

I would consider removing and thoroughly cleaning with soap and water but NOT the bearings. Dry completely. Reassemble and then coat with silicone spray.

The reason I would not add the silicone spray before assembly is that you would want nothing to interfere with the typical friction hold of the coupler screws.

If you do find that the coupler screws are not maintaining a tight hold, a very small drop of the blue lock-tite would hold it. DON’T use the red lock-tite.

I will also try this out! Thank you

Okay I’ll try and remove them and clean them and relubricate. I lubricated them before but never cleaned them yet. Thank you!

You need to clean all the rust off the lead screws and lube them. You also need to clean the rust off the guide reals,lube and adjust the Z bearings.

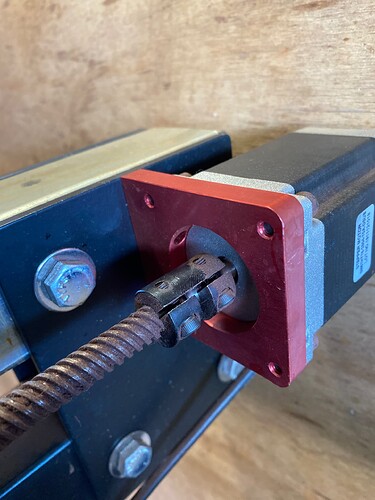

Cleaned all lead screws, lubed and reset. Still same issue. Also tried the tight tolerance on the toolpath and same issue. What else could it be? Here’s some pics

New tips also, and the plasma cutter will misfire sometimes. That last pic shows were it didn’t even cut through the material with 40ipm, 45 amps on 1/4” plate

Got to hand it to you. You cleaned those screws up quite nice. I had a similar thing when I assembled my torch wrong. Make sure you don’t have any thing in the wrong order or something omitted.

If you can see a consistent defect in the holes, you can turn the torch 1/4 turn and if the defect follows the turn, you can wonder if it is something with the torch.

That straight cut looked like the work clamp was not getting a good connection but if that was the case, I doubt you would get the holes to cut at all.

I am assuming the pictures are of the topside and it almost looks like the metal is being pushed upward. That could happen if you are moving too fast for the cutting capacity of the cutter (amperage). If you move too fast on holes, they will not get a chance to cut out completely.

And you checked your dessicant beads, I assume: nice purple color…not pink.

If the torch gets any movement in the holder or there is any slack in the torch assembly, you will get usual and unpredictable shapes. @mechanic416 suggested adjusting the z-bearings. Look on the Langmuir site for assembly instructions for the table. It may have changed a bit from the table you have but it will give you a good idea how to do it.

This is the link for the CrossFire Pro:

https://www.langmuirsystems.com/pro/assembly

Thanks man! I really wanted that to be the issue haha. I’ll try out some of the things you mentioned.

I did notice the plate is bowed up a little, would that cause that issue?

I changed the tips and same issue, also I go through tips fairy fast.

Also found that one angle cut is straight but the rest have a slant to em.