Oh this plug is a pain in the balls I was under the impression that it would have the same plug as my welders I couldn’t be any more wrong now I have to get the electrician in to change the face so I can plug in grrrrrrrrr not good

Well this will have to do for now but I’m not liking this you too I have to walk around to get to the fuse panel not good

We also located the control box to the front leg so we could turn the thing off if we need to in a hurry not sure if all the cables are going to reach now but we will find out tomorrow

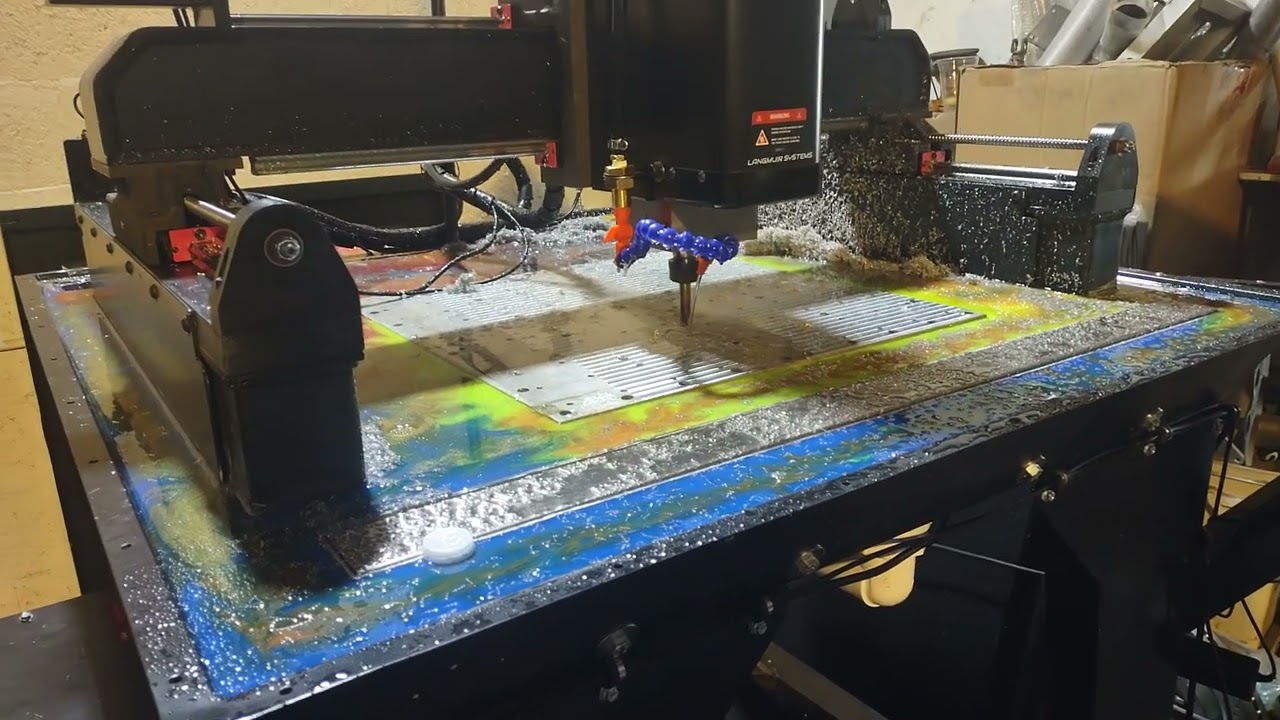

Another day another 50 cents well let’s keep looking forward and see how long before I can start cutting chips

For the plug, you can just get the one that matches your welder outlet at Lowes, Home Depot or any hardware store. Cut off the existing plug off, strip back the wires and install the new end. It is a 10 minute job once you have the parts you need. I find it best to have all 220V tools in the garage be wired with the same plug so you have the option of moving things around.

If you rework the doors and they no longer open outwards, then you could mount the display vertical on the side of the enclosure using some drawer rails. WIth the rails you could slide it to the side to have open access to the enclosure opening while working, then slide it back partially covering the opening when not in use.

My install is very tight for space, so I plan to modify the Langmuir arm and laptop stand to swing completely out of the way when not in use.

adaptors or pig tails are available

AC WORKS® Welder 6-50P Plug to 10-30R 3-Prong 30A 3-Prong Dryer Adapter – AC Connectors

search for this 6-50p-to-10-30r-adapter

Thanks for the link. Just ordered one

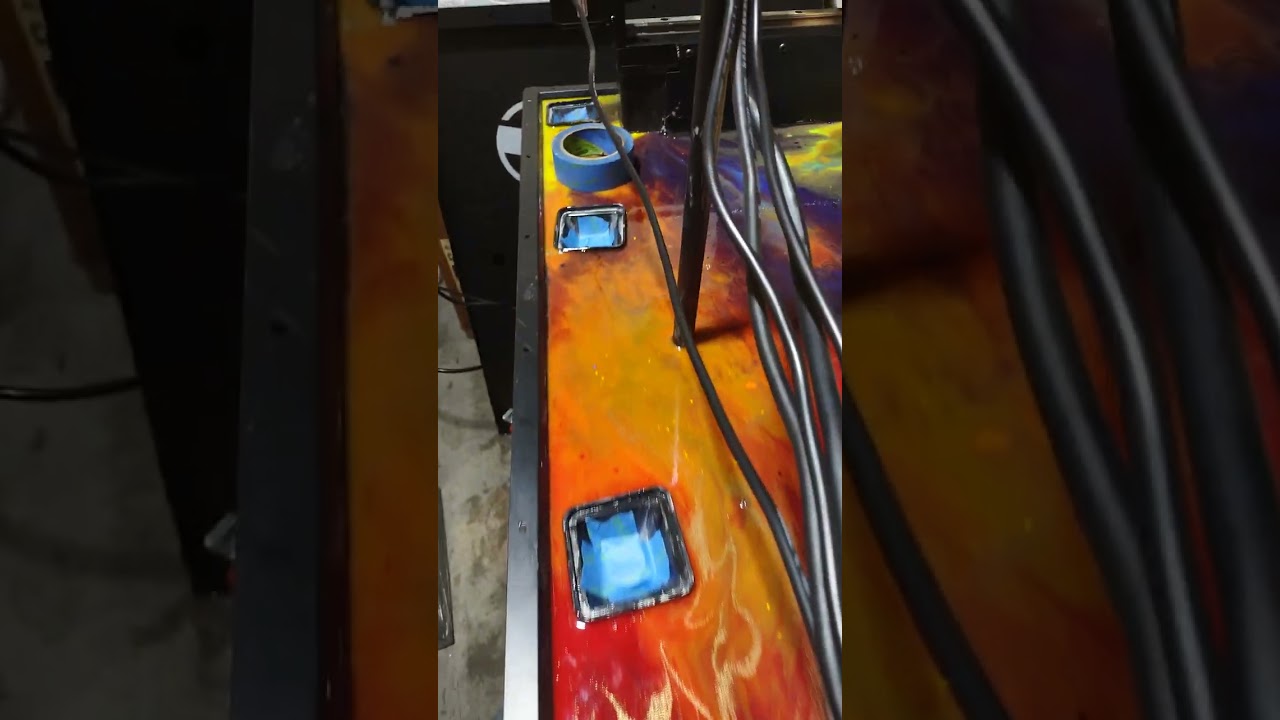

We are looking at that right now what we are looking into is linear rails for the door once we find these we’ll probably make the doors and lexan or a clear plastic of some form

We got some movement today and was able to move backwards forwards up and down want to do cable managemen

This is what i am looking at to do my doors for the MR1 sliding doors project down the road

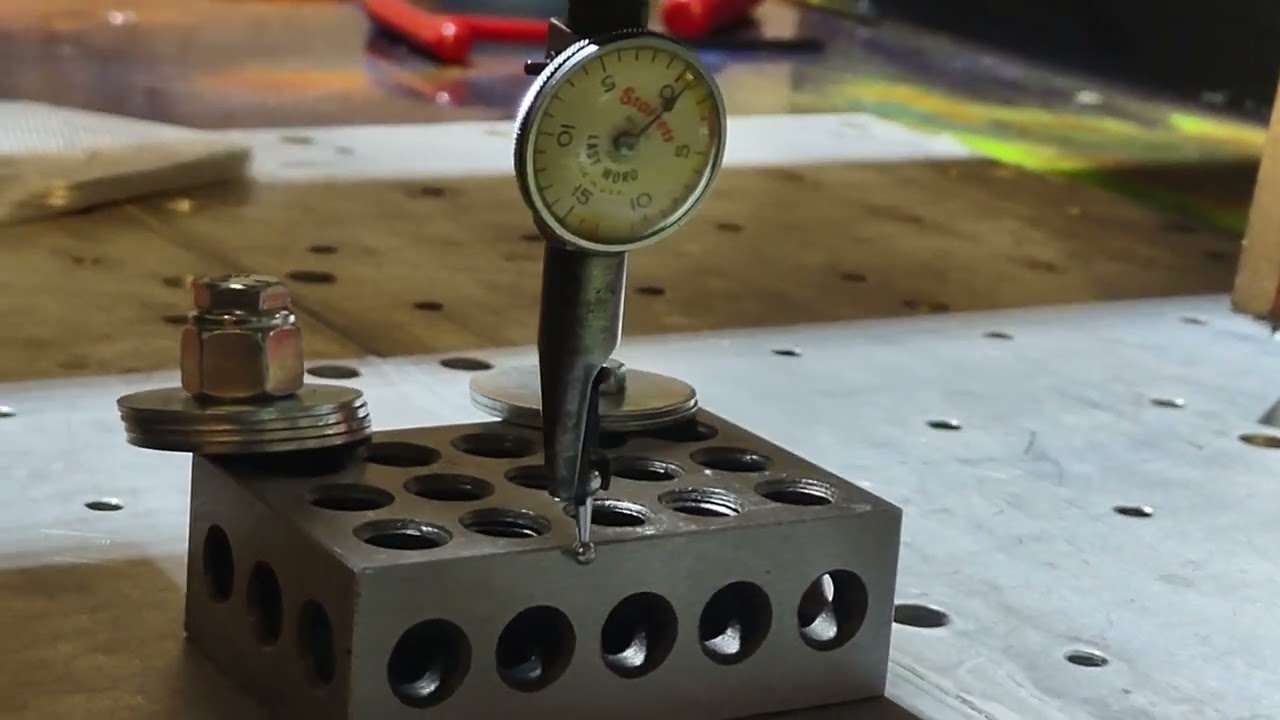

I am a little bit unhappy with what you have to do to get this machine to be straight the guy on the video is constantly doing work off camera this does not help you to find out how long it takes to trim this machine in this is a long and boring process to go for and this is only one of the things that I have the hump with more to come

We are well on the way but there are 1or2 things I am not happy with I do wish this guy will show you what he is doing off camera this drives me crazy trying to figure out what might be the right way to do this or not

is that a compound turbinski on an air cooled VW ?

Yes it is and it made 415 hp on the ground

I must say a big thank you to the lady in the upholstery shop for making my cover for the touch screen display and for the unit itself