Hello guys I got my mr1 this weekend I hope I can post some good pictures on my build I have a friend who’s helping me build this due to I could not wait for a fully assembled mr1

This is going to be a long road because I do not know what I am doing but I’m willing to learn

Day one of this long journey with my hubby mill I am glad to open the box without any damage parts like I have seen on The forum

2 Likes

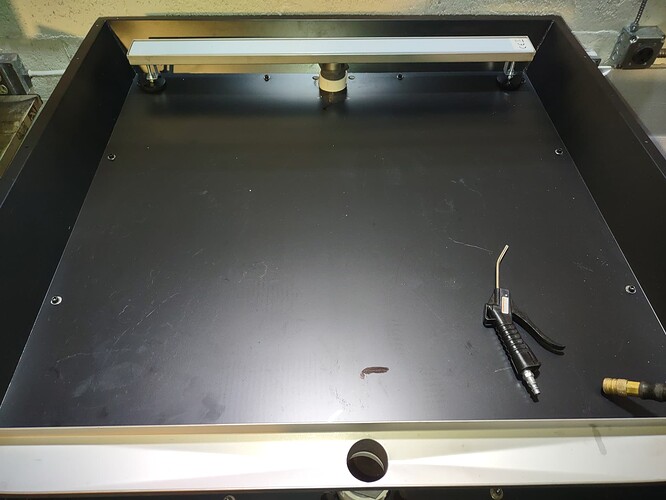

Best out the box is the table and we’ll see where we go from here

Build a steel frame to roll around on when I need to clean up

3 Likes

Today we took a look at the problem of drainage I’ll take some of the ideas that I have seen on The forum and on YouTube to fix this note this might not be the way for everyone but I think this will work for me

After some small changes we looked at what was going to be the best way to drain without too much mess we tried to or three different ways

1 Like

We quickly found out that one of these will not work due to the placement of the frame so we need to make new mods to get over this problem

We took a look at the dreams that came with the unit and decided to drill bigger holes for free quarter inch AC drip lines

1 Like

After sometime looking at this problem we decided to go through the whole we already made with the PVC pipe This look like the way to go for now

1 Like

The more ideas I see the more confused I get there is a ton of real good stuff on YouTube as well as on this forum but I’m trying to keep it simple and on a budget

One of the things that I am looking at is the final dream before the pump I’m looking to use 100 micron filter to save the pump cuz this thing is needed for most of the work I might be trying to do so my thinking is protect the pump and it will have a long life without any problems

1 Like

My machine is in orginal form. If I was to do it over again installing a drain system like yours would be it. The standard drains work but, a total pain in the a$5. Glad you almost up and running.

1 Like

One of the things I see is that concrete will not stick to a smooth surface and there is no way that this thing will stay together over time with vibration there is nothing holding the base to the carrier so we drill some holes and put 3/8 16 boats through the floor to keep everything in place for the long run

1 Like

We also think it would be a good idea to welding some tabs to keep it all tied in.This is a lot of work and this is only the first day I do not see this thing up and running for at least two more weeks

This setup for corner to corner with that flimsy thing to take a measurement from is madness the floor is constantly moving and this thing is constantly wavering around this took up so much time and I looked at the video on YouTube and that did not help either so we had to brainstorm how to keep this thing still so we can get our measurement

GRRRRRR NOT GOOD

It’s just a rough measurement at this stage before the concrete goes in- Once the concrete is in it will be extremely stable (when it matters).

2 Likes

We’ve got a machine here running for 3 years every day (cast iron and steel mostly)- the concrete is perfectly intact. The reason that we do not advise mechanically bonding the concrete to the tray is because if one of the legs were to be bumped, it puts a load through the concrete which may cause it to crack

One other thing to keep in mind, the more ‘stuff’ there is in the concrete, the less concrete there is. Stiffness and mass damping of the base are what give MR-1 its performance.

6 Likes

I would have to disagree with you on this for the simple reason is I have poured hundreds of car Parks hundreds of walls and car park suffer when vibration allows the steel pond to move so vibration of any form will separate a a surface that is non-porous does not have the quality of a porous surface to bond to concrete was my life for over 40 years also what you have to look at is there are many forms of concrete from small pee aggregate to large pee aggregate there are fiberglass infused concrete known as Kitty hair that pump grouts and various other forms of concrete out there this is the most basic form of concrete being used in here which means it does not have all of the bonding qualities that you would get from a kitty hair concrete mix of 4,000 plus PSI

I did a small video to show how this thing works and I cannot post it directly on the forum I think I have to go through YouTube and put the link so you can see how well it works the large drain has a 2-in outlet which I’m going to cover with 100 micron filter this should keep all of the debris out of the pump but this is the way that I did it but there may be better ways to do this but this is what we have for now I will be looking forward to help from members on the forum when I get this thing up and running

1 Like

Sounds great. No worries. We will assist you in making a chip mess.

I put that same drain in the back of mine, you won’t regret the extra work to make it fit.