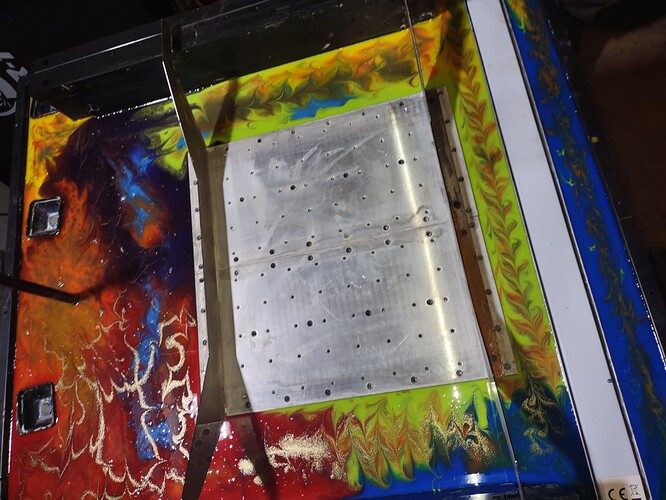

Well you cannot say anyone else has one like this not yet anyway show your creative side let the juice flow

Be nice now this is not for everybody but this is what we do we’re in our flow Florida style art deco

No, He doesn’t have one of those but, boy life was a lot more fun then!

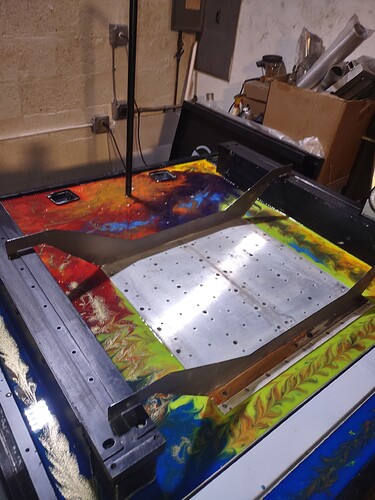

I am so glad this guy Jimmy is building this unit for me there is no way I would get through this without him

Hopefully in the next two to three days we may have it running to the point where we can put on the enclosure

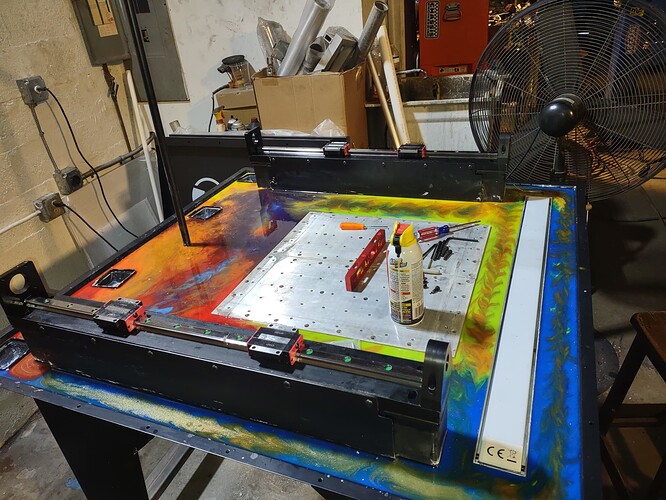

Looking at the enclosure it’s a bit hard to have a large pair of swing doors has anybody thought about sliding doors if so how would it go about doing it there must be easy way to do this

Spindle Cover: Yes it is. Unless you are 4 ft tall. Much less bending over to load end mills etc.

I’m going to look into this and see how many problems it brings and if it’s worth it having the two large doors is not so much the problem it is the touch screen that sticks out so far into the shop I would like to be able to mount the touch screen like a regular CNC upright against a wall or in a cabinet it may turn out a bit funky looking but I cannot keep swinging a door backwards and forwards that leaks all the time. I did take a look at lots of the mods done to the door with various plastic covers and so on but no one has made an attempt to do a sliding door or a pair of sliding doors like a full-size CNC

With some interlocking Lexan panels you could make a roll up garage door (drips when open and keeping chips out of the track would be challenges.

You could also do roll up door mounted on is side and supported from above like conference room partitions. The door panels would then wrap around inside the machine along one of the Y-rails. The sideways garage door would solve all drips on floor concern and the top mounted rails would provide better debris protection from chips.

Another option could be to make a bi-fold or quad fold door out of interlocking Lexan panels (think closet doors). You would not want them to extend out past the machine due to drips, but there is 8+ inches of room to have them open into the enclosure.

It probably would not take much to modify the two existing doors to be a single bi-fold door that would open to the right (as you stand in front of the machine) - Probably need to fold outward for clearance or offset the fixed pivot point to be mid door. Managing drips on the floor would be the challenge, but some creative drip rails attached to the bottom of both doors might help reduce.

I haven’t really thought much about the enclosure aspects for my build, but now you have me thinking…

I like where you’re going with this but the only thing is anything that lives overhead runs the risk of having coolant run down your neck when you look in. But I am open to all ideas to get around this problem thank you

Just putting lexan panels on the inside of the doors, bending down the lip inside slightly, and adding some door weather strip on the bottom took care of 95% of the dripping outside. I have thought about just moving the left door hinges to the center to bifold, but am worried about that much weight on the enclosure flange on the right side.

I can share some photos later, but I put the PC on it’s own cart (which also holds my tooling) that is next to the machine. This lets me roll it out beside me when I’m working, and I can slide it next to machine for better storage. My PC is too large to mount it directly to the cabinet, though maybe I could make it work with the right swing-out arm. I’d still need the cart for tooling.

I also mounted the control box on the back-right leg. This let me install the cabinet closer to a wall and gives easier access to the power switches. It reduces the already terrible access to the e-stop switch, but I fixed this by wiring in a second e-stop which is located on the front-right leg.

Here is one of the tracks that could be mounted at the top of the enclosure, some 6-8" wide lexan panels with hinges between them hung front to create door that will slide to the side and back down one of the side walls. Evertything would stay inside the enclosure and the rails mounted at the top should be well protected from splashes and debris.

I like this a lot I will look into this and see what I make of it thanks