are you using the clamps to pull coplanarity closer?

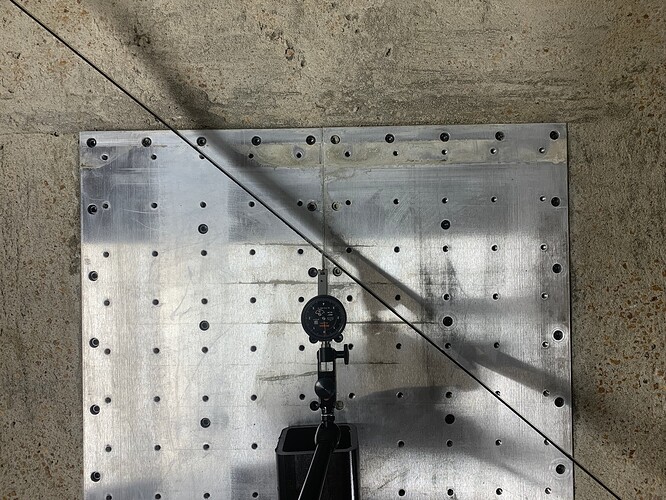

Yes sir. And so far after doing a check today with them removed and concrete basically done, i am sitting at the following with no shims.

I might have to give that a shot although my coplanarity gauge is so bent up from shipping its pretty difficult to use repeatedly

Well we got a few more things done while we wait for concrete to cure. Made the side mount panel for the control box and drilled and tapped the holes. Mounted the control box.

My Lord…when will the concrete ever be done curing!!! Its killin me!!!

The end of day 5…Finally!!! Time to start the Epoxy process.

Enjoy yourself pal. Then wait some more. You’ll be up and running next week.

Note: The spindle break-in program takes two hours or so to run. Don’t panic when the G code is not advancing like you think it should.

Roger. Thanks for the tip

Good to know I was wondering that. Once started its all hands off? I have some other things I can work on.

Yeah, I watched it for a short bit, but it just stays in place and goes up and down in RPM

Epoxy flood coat complete…Man it looks good! Floods very nice. HF heat gun did awsome at getting the bubbles out.

Wow that epoxy looks like glass. Beautiful job!

Thank you. Didn’t really do anything special. I think the key is the heat gun. The epoxy flows really nice. My only concern is that the epoxy doesn’t really get in under the y rails between the y stiffeners to seal that concrete. Exposed concrete. I guess it will be ok. Has this ever been a problem @langmuir-daniel ?

No not a problem at all- you could remove the y rails and apply some epoxy under there if you like.

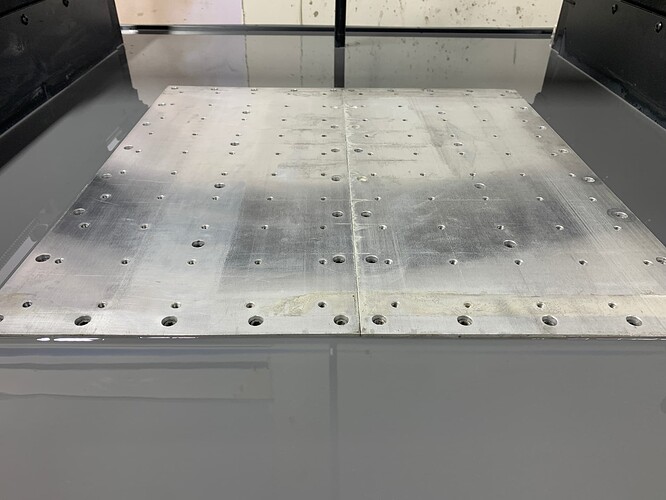

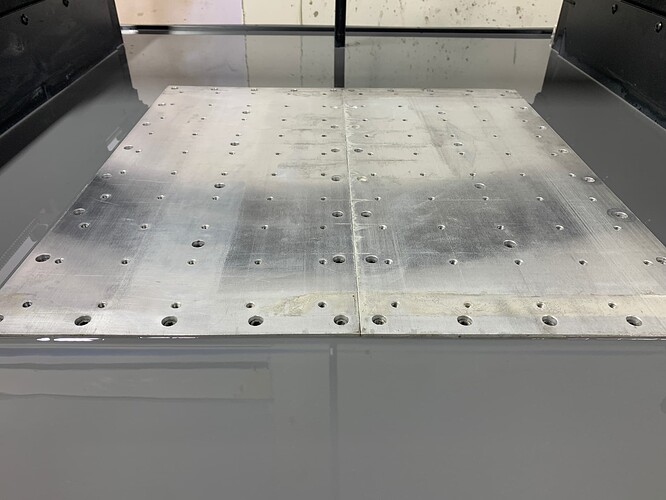

That’s good to know. Man I got the coplanarity dialed in and didn’t want to do that with y the rails. ![]()

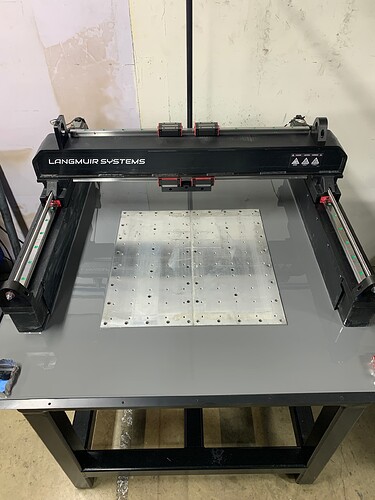

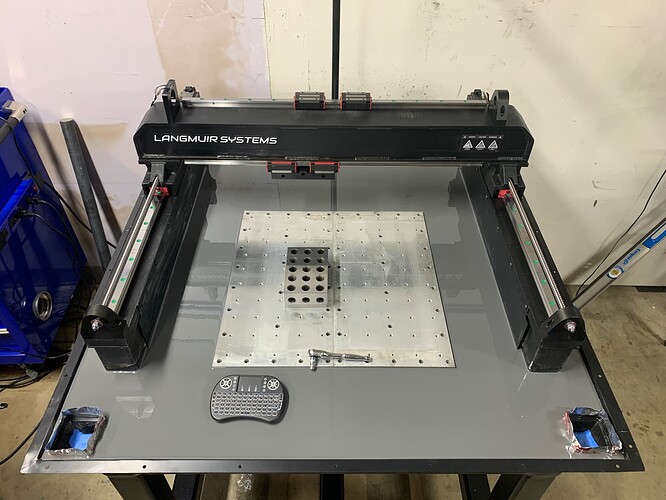

More progress made yesterday. Y and X axis’s complete. Spindle shimmed and installed. Gantry squared and hard limits set. Did a first homing of the machine and it went great. Started a pre assembly of the enclosure to make sure things fit right before final assembly and caulking. Slow process but satisfying. You can actually pre-square the X and y before you put the spindle on. All you have to do is attach your indicator to the bottom of the XZ spindle bearing, the bottom one, and are able to use the servos for the Y and you can manually push the bearing block left or right for the X. This allows you to get it very very close before you put the spindle on and then you can fine-tune it after the spindle is installed.

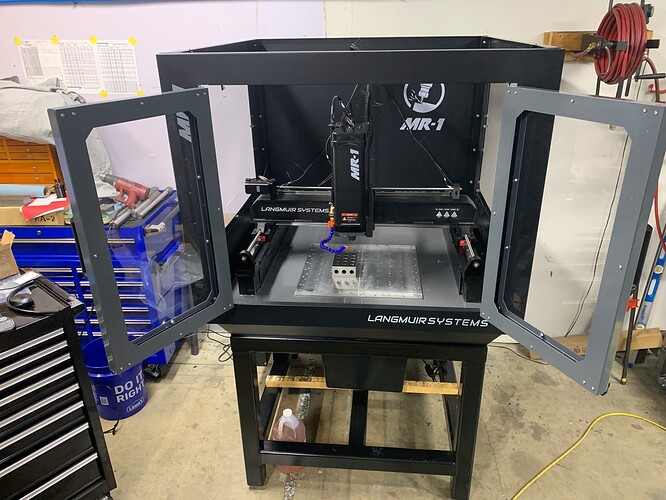

Well yesterday was another productive day. We got the soft limit set, all the wiring pretty much done and in place of where it’s going to be but just a little fine tuning later on. Still have to install the touch probe and the tool setter but that could be done at a later date. We got the enclosure all put together and sealed and installed the corner drain blocks that we printed off thanks to #custommetalmke. They are great.

Hopefully we will have a tight leakproof machine. Getting very close to surfacing the plate.

Not sure where to put the lights we got thanks to bigdaddy2166’s recommendation.