Roger that. I of course am not putting anything down. Laser cut is awesome but even it has flaws at times. I am just fortunate to have a mill to tweak things. I love this machine and y’all have done a great job. Keep up the great work.

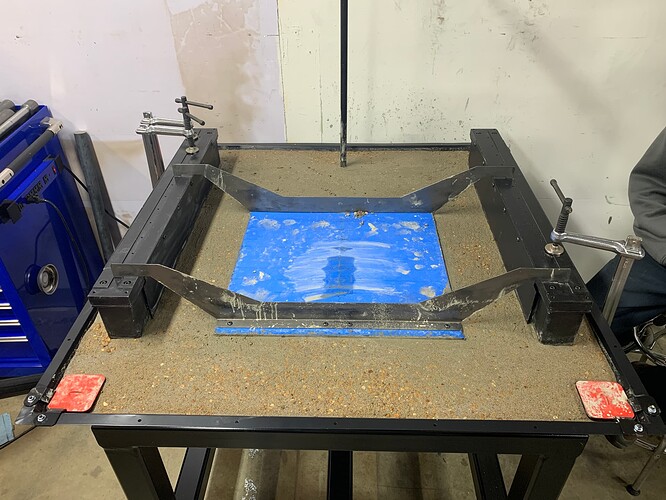

Well, base stand off to powder coat. Hopefully get by Friday and start assembling.

What does it cost to get something like that powder coated in your area?

$150 power washed and degreased. Not sandblasted unless it really needs it. I normally use someone else but their turn around time is 3 weeks right now. Using someone different this time closer to me. Should be done by friday.

Thanks for the information. Just gettting my feet wet in the powder coating world as well. To many hobbies.

I hear that.

I couldn’t file any better than the original cut, I milled it flat also

Thank you for sharing each step with the community.

And Great looking welds.

For anybody that has put theirs together, have you got a recommended distance from the wall to place the unit and still be able to do what you need to do while assembling and final placement?

The cabinet needs to be 7" from the wall. Thisw allows the wires plugged into the control box to not be folded over. But with yours, you could mount control box farther foward.

roger. Thanks

I have been busy so have not made much progress with the assembly, but am positioning the tub now. It will be placed in a corner, and my lathe will be beside it along the back wall. The default location for the control box appears to be on the left back leg, which means the end of the lathe will be close to the control box, making it hard to service.

So the question is, Is the cabling long enough to move the control box to the left hand front leg? I have no problems with modding or welding in a support.

Cheers,

MIke

Yes, I believe so. Like I told sr71xjet. You need 7" from wall to cabinet and 11" from top of legs to wall.

The control box wiring sticks out the back and any closer will fold the control wiring.

This is at 7" from cabinet

With my new stand, Ill be making a mount to work with that.

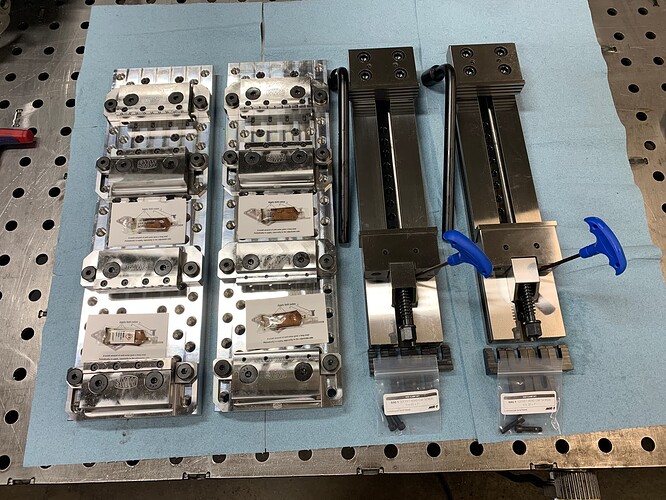

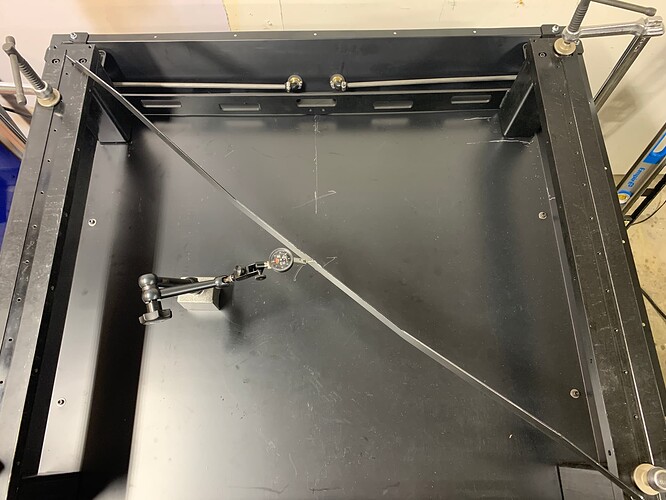

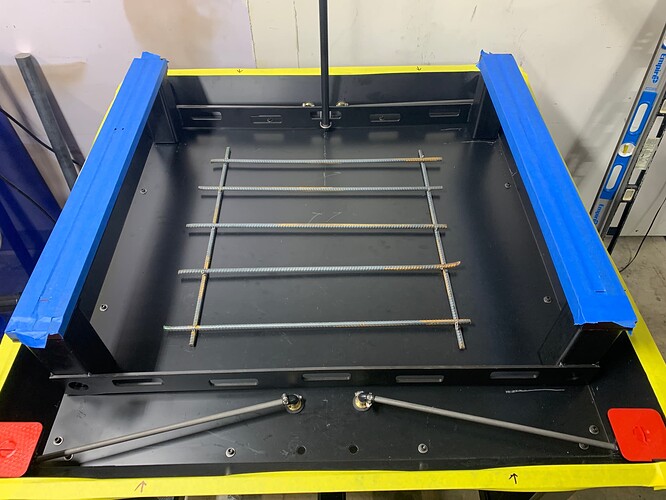

Holes drilled and tapped . Everything lined up Great. Pan installed and distanced adjusted according to directions. Stand and pan put in place for concrete pore. Drain holes relocated due to 3" tubing. Coplanarity has been dialed in to aprox .0002.