Jim,

You can make them if you have some 1/4 remnant laying around.

See posts below from the “its been a while post those projects” thread.

2

Cut lots of large box tube end plates, hang plates, hooks, gussets, etc. Cut some riser plates for when I install the XL kit parts.

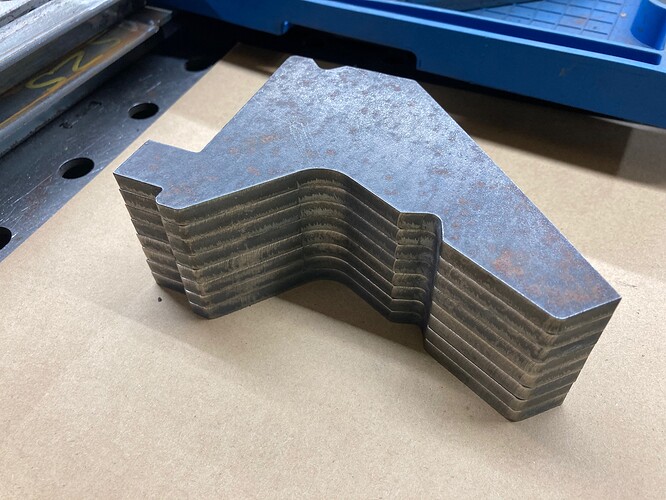

Needed some gooseneck dies for the Swag Offroad heavy duty finger press brake, but their versions are short, so designed larger ones and hope to try them out soon. Just 1/4" plate. I’ll weld them in groups for different widths or 1", 2" etc.

I’ve made a few dozen capture nut mounts from 1/4". Weld them to 3/8" nuts to mount hockey pucks as feet for different projects, a bench grinder stand, a couple radiant heater stands for a restaurant. Still trying to improve my tig welding.

Bought some rollers from McMaster Carr and designed an adjustable roller guide for cutting long tubing and angle iron. First of several of these I am making.

All on Crossfire 2x2, Primeweld Cut60, ViaCAD 2D / Sheetcam / Mach3

![]() holla2040

holla2040

Craig, here is the DXF for the gooseneck. It will require a riser on the end posts if using a Swag finger brake press since I made these longer than theirs. I’ve cut 20 of these and welding them in groups of 4, 8 and 8. I think the better method might be to add through bolt holes in the file and squeeze them together with an all thread. I have cut these out of 1/4" plate. I have no easy way of handling thicker stock.

gooseneck die v1 radius.dxf (11.1 KB)