I just meant centered as in not hitting the sides

This design is my biggest pet peeve with this company. I have two crossfires and an Pro on the way. Woulda ordered the pro long ago but I just wasn’t happy with the design. I bit the bullet. I like this company and the forum and said I’ll just give this a shot. I make my living off of this machine, and my welding. I have a ton of whip in my extended lead screw. May upgrade to a 1/2" when I get time. I also plan to make taller stansion plates to raise up the Y axis so its bearings aren’t so close to the water table. Anyway, sometimes it take a while to get the set screws to set. Iv had to re tighten mine a ton. The worse is if they come loose during a run and totally screw up your run. I usually check my set screws every couple of runs. Make sure you aren’t over tightening one end. I’d bring the machine to the area where you have chatter, loosen it all up and then slowly tighten both sides back up. test that out and see it it helps.

Yeah I have had it come loose a couple times during cuts and it sucks specially if you’re doing a big piece. backtracking on G code is not ideal and doesn’t always turn out well.

I loosened the two bolts to the x-axis lead nut jogged up and down the axis no problem. I then jogged it to the place where I having the most issues and re-tightenadd the bolts. This helped a lot with the chatter but I still can’t jog all the way to the positive far end of the x-axis. it stops about 6 inches before the end and the coupler starts to spin. I have tightened down the bolt on the coupler so much that it stripped the allen head and I had to turn the bolt into a flat head to tighten it more. I don’t think I can physically tighten that bolt anymore without stripping the threads on the Cupler but it’s still spins at the end where I’m getting that resistance. very frustrating.

Since I have got rid of the chatter and I am only limited by the last 6 inches of the table it’s not a huge deal but I want that last 6 inches of travel and I don’t want any resistance of travel on a lead screw. It should be smooth every direction until I can’t go any further.

Langmuir has been excellent with support and this forum is awesome. I still would recommend people going with Langmuir because the quality support and the fact they have local support in the states who speak and write understandable English (unlike my English lol)

Once you’ve verified you’ve gotten the setscrews tightened sufficiently and correctly, you can use green Loctite threadlocker to keep them from loosening. Green Loctite is different from red or blue in that it is put on after tightening. The green is formulated to wick between the threads of the bolt & but and then hold.

I’ll mention this as it may be adding to the resistance. Check the X tube for any scratches. I had some scratches on one of my Y axis. When I manually moved the axis I didn’t really feel any resistance. But it would stop the machine dead under power. One minute with a file to take the burrs out and it was solved. See videos below.

The couplings and their fasteners seem to be the finest Chinesium. On my X I ended up using another M4 cap screw that was longer, as one was missing. I think the one in there is M4x12mm. With the longer/better grade bolt I was able to crank down on it more. I do wish they had a more positive locking (keyway) mechanism but I realize there has to be compromises to get the price where it is.

Before

After

Okay, so fixed the issue with the torch binding up at far end of the x axis by chance.

My table was not 100% level. After leveling out the table, for some reason I no longer have hesitation or binding at far end of axis.

BUT my chatter is still slightly present. I want to get rid of this chatter completely.

After improving my table I did a test cut at the far end of the access to see if the chatter has any impact and it does. I really need to fix it. See video

I would loosen the X axis nut and redo

http://www.langmuirsystems.com/pro/assembly#connections Step A6.

If that doesn’t help:

- Look for any burrs/scratches in the X rail. I had a few burrs that would stop the Y Axis dead. Filed them down and no problems since.

- Remove the X axis lead screw and verify that the carriage moves freely in that area. If it doesn’t, repeat the steps to set the bearings. https://youtu.be/xCbOJz-zfl8

I have taken that x axis lead screw thing off so many times in fact Langmuir sent me a new one and I replaced it not too long ago. New one didnt help with anything but once i leveled out my table, the resistance went away completely and now i just have a little chatter left. ITs not much but you saw the results in video

So with the nut disconnected and/or the lead screw removed, the carriage moves freely in that area?

Are you using any lubricant on the rail and screw?

Yes it moves freely in that area when its removed. I probably lube my lead screw more then needed (every time before using machine). I use the 3 in1 lube

Did you flip the lead screw end for end in your attempts to fix things?

Sometimes there’s a bit of bend or twist or flex that when you flip it will end up in a different part of the carriage travel and it will smooth out.

Is anyone using a drill bit to dimple shift so setscrew can’t spin? We do this on most of type machine building

THAT is an excellent idea. So stupid how they designed that coupling device. They should have put a slot or grove in it so it cant spin without turning the lead screw period.

So just take it off and put it back on opposite side up?

No. The long lead screw is what I was referring to. Flipping it end to end will move the end that’s at the front to the back of the machine and vice versa.

That means you need to undo the couplers and the nylon lead nut so you can back out the lead screw. Then you flip it end over end and put it back together. Retighten the coupler setscrews and the lead nut and check to see if that fixes the chatter.

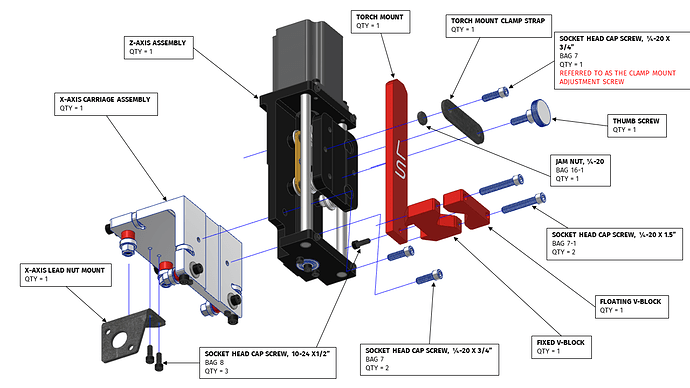

Also make sure that the lead nut mount is screwed in all the way. mine came loose and i had the wavy lines like you did because the whole thing was just “floating”. It’s the L shaped bracket that the lead nut screws on to. bottom left in the pic

I’m having a hard time wrapping my head around what you’re trying to get me to do. This is my x axis that we’re talking about. I didn’t think There was a way to flip it from end to end because it can only go in one way with a coupler device on the left side where the motor is. Would it be too much to ask you to make a little short video of you pointing out the part and kind of explaining it not actually doing it but just kind of giving me a visual?

U get yours figured out yet? I don’t know if u saw my comment but making my table dead level helped a lot but not 100%

are there screw holes on both ends? i never noticed