Thanks Jim. Just to be clear I didn’t come up with the idea of this kind of saw. There are many commercially available that will do some or more of the things mine does. There is a $1M+ Italian saw that has independent Y axis for some really cool cuts. To a Chinese knock offs for about $50k that will do simple cnc (no inner contours though).

Absolutely incredable!

Thanks for posting this , love the video, that is so cool!

That is cool as hell!

I currently only use my crossfire for hobby purposes. Back In high school I made the smart decision to spend half my day at tech school learning useful life skills instead of learning useless crap. I took Machining for 3 years got all my NIMS certs and went to Penn State for a semester for manufacturing. Somewhere along the lines that semester I decided I didn’t want to stand on concrete all day. So I moved back home and got my business degree at a local college and now run my family’s company.

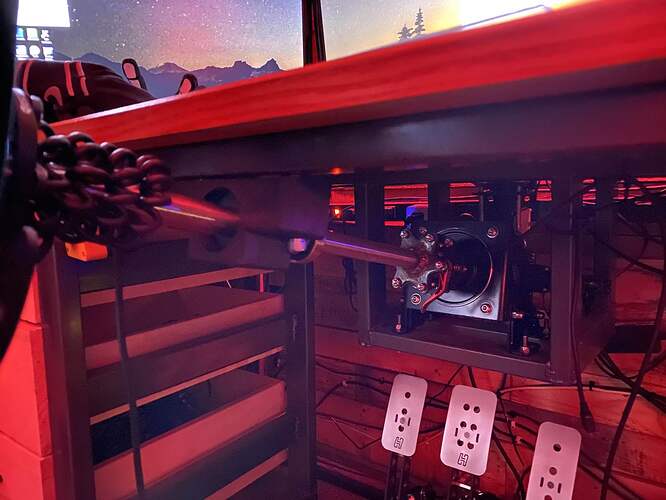

I would like to start using my crossfire pro to make some money. I haven’t cut anything yet on my new pro table but had the original crossfire. I’ve made a couple of signs but mostly use if for making custom brackets. Most recently I made some custom brackets for my Sim racing rig.

Thats going to be so cool. Be fun getting drunk and seeing who crashes the most!

That motor the wheel is attached could easily snap a wrist no exaggeration lol

Looks like PlayStation gone wild!

I work in the metal industry, but this machine is a private purchase , would like to run this as a hobby and see where it takes me

The possibilities are endless.as to what you can make and where it will take you. Have fun with it.

@JonesM86 I meant to reply to your question before but I forgot. I just tried to explain how I index parts or artwork with Fusion and Sheetcam in this thread. Here’s the link. Hope it helps and if it’s unclear, let me know and I’ll try to help.

Lot of luck  great new tool for the shop ! I think

great new tool for the shop ! I think