Curious, do you think you would have as much warpage if just making a straight line cut? I can see slowing down for all detail would cause problems.

Unsure but makes sense… Right now I’m just trying to get the machine to talk to my computer. halfway through a cut it disconnected and won’t connect. Fun stuff

@not_neil_armstrong - I get that about once a week.

Try closing FC, then open again. If still nothing, Close FC, cycle the power on the control box, Disconnect the USB, power on the control box, plug in USB, open FC.

If still no - reboot everything.

Don’t you end with this motion?

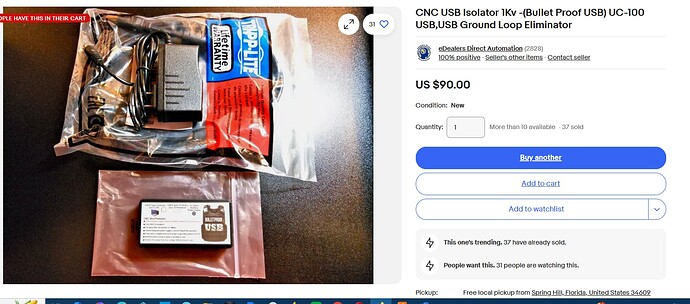

By the way, I got my Bullet Proof USB isolation device. Haven’t tried it yet.

@not_neil_armstrong, you might consider this gizmo:

haha, no I didn’t… that’s gotta be where I went wrong!!

Will be interested to learn more about the CNC USB isolator.

I don’t want to railroad this thread toward a discussion of electrical interference, but that might be what is going on with you. Many have noticed intermittent connection and freezing of FireControl. Sometimes FireControl continues moving along the path but the torch doesn’t.

My first issue with that might have been caused by a low battery and the laptop allocating resources away from the USB (only a theory, not proved).

BigDaddy really thinks highly of the bullet proof device to stop ground loop disturbances thru the USB and to provide necessary power thru the USB. As you know, the enclosure relies on some of the power from the computer: you will see LED lights inside the enclosure when the computer is connected whether the enclosure is turned on or not.

So I got one. Metal is too expensive to have the USB/computer not have a good connection with the table. End of story.

Loved you piece. Never tried to cut something that thin. Good for you. You will get it figured out. Most people say to use Fine-cut consummables for thin metal, if that is offered for your plasma cutter.

Yeah, and I still have THC issues. Not as frequent, but I have them.

Well I cut some 18 ga

These were 7x13 so mostly straight lines.

Settings:

These were cut with a razor 45

Machine torch std consumables

45amps 180 ipm

.5 pierce

Very little dross and very little warpage if any

Slowed down to about 120 ipm on corners

Water about 1/2” below sheet

Creative, practical, unique…

What can I add: You’re amazing!

oh, stop! but thanks.

If you ever want to sell your secret as to how you get 48 hrs worth of work done in a 8 hour day I would be willing to purchase it! Between you, Jimmy, and Tin I am feeling like I need to pick things up a notch or 2000🤣

Very nice as always!

@holla2040 That’s an awesome project! Great job!

Thanks, glad you liked it.

Everyday is like Christmas for you isn’t it? ![]()

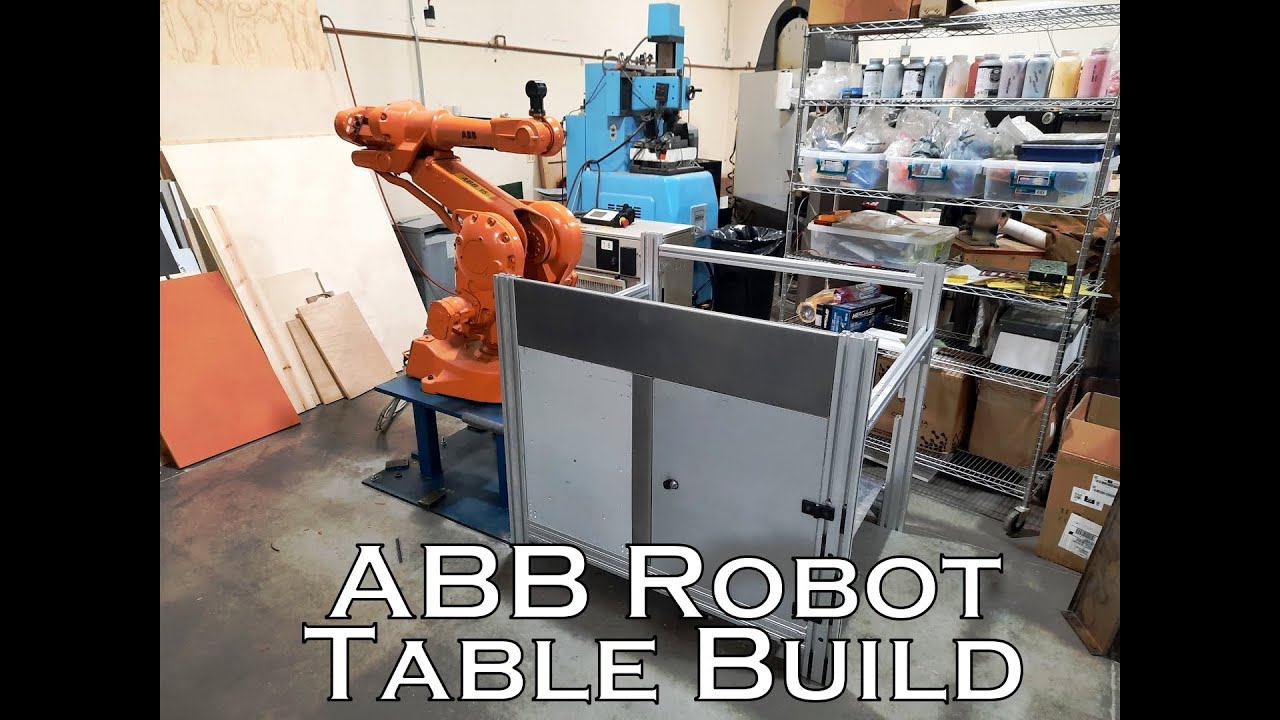

So is ABB the brand of robot?

Garage has been a mess this past week due to shitty FedEx shipping

USPS delivered my CPC kit 2 days early so I installed that

Just need a machine torch now

Nothing yet, but at least FedEx delivered my welding table legs.

That and Hypertherm accessories and consumables are on sale so I ordered a machine torch this morning.

Lastly, the generic barrel plug arrived from Amazon so my CPC cable is ready to go; just had to snip off the torch on/off plug since it was meant for an XR.