everything they do is like this, Make It Extreme

XL user here. I just figure that with a Z-axis, it’s like a mini pro!

Hey Terrance and @OldNBroken, no one is going to look at your table ID. All projects enjoyed equally here!

Of course if we start getting a lot of XR projects that take a full 4X8 sheet of material, there is going to need some 'splaining as to how it was indexed on the smaller table. ![]()

Nice gauge. Bigfoot is a nice touch. I’ll be jealous of the powder coat setup. My garage is suffering from all the painting.

I started the thread. I set it up the way I did modeled off a thread(s) on a truck sight (Tacoma World) I frequent where each generation of truck has a thread like this one. I thought someone might start one in the Crossfire and XR areas of the forum.

The point of the segregation is just so people with like machines see completed projects that others with a machine with the same capabilities. In this case, projects requiring the larger table on the Pro vs the non-Pro. It would be same if someone started a “What have you done on your XR Today?”.

Your always welcome to post your stuff here. It wasn’t meant to excluded anybody.

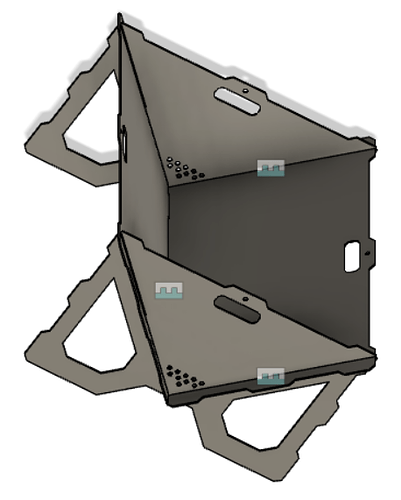

Collapsible fire pit inspired by one that Lift Arc Studios made. The 4 parts can be bolted together and carried with the handles. I have future plans to make a grill that will be slotted over the handles.

This was entirely designed in Inkscape.

Mistakes were made with the slot placement, but I made it work and will fix that in the drawing.

You might consider something like the hitch pin for connecting:

I kind of like the carriage bolt with a wing nut to keep it from rattling.

I did one of those for the spring fire pit contest… the holes above the handle are for a bolt to hold them together… but looking at it now that hole should be below the handle… might not feel to good wrapping your hand around a bolt ![]() Also I need to add more vent holes.

Also I need to add more vent holes.

I still haven’t cut it out but the DXFs are here:

These are a work in progress… wanted to post them before the end of the month. ![]()

You can put your custom design on the ends. I did the assemble in fusion 360 but have not cut them yet so user beware. I was waiting to post them till I was able to cut them to make sure they worked and so I could post some pics but I won’t be able to get to if for a bit.

Collapsible fire pit. You need to cut 2 ends and both side 1 and 2

Fire Pit End 3_16.dxf (5.5 KB)

Fire Pit Side 1 3_16.dxf (14.1 KB)

Fire Pit Side 2 3_16.dxf (6.0 KB)

I have always enjoyed cooking on a Swedish fire torch and/or log rocket stove. In the past I have used grille I made of rebar. Thought it would be fun to design and cut some. I have held off on posting these as I wanted to post with pics but haven’t had the time to cut them yet.

I cut out a few steel fish yesterday. For some reason I’m starting to get torch rising issues about 10 minutes into a cut now. Hopefully this weekend at the shop I’ll be able to sort that out.

Nice! Powder coat or wet paint?

I had my table do that a while back as well. Turned out that my charger on my laptop ungrounded of course was touching the USB to the control box. I know you will figure it out just a possibility I had dealt with.

I think these fish will end up being heat tinted the clear coated after their acid bath. The waffle pattern is from the sheet being racked with expanded metal .

Thanks , That is the first place to start.

I do like the flame finish. I don’t have may people ask for it.

Here is a picture of some olive tree crosses I did a while back.

Beautiful color on the tree. Color change is quick. Are you using torch or oven or both?

Usually I use a propane rose bud they work the best. I have done them with small hand held propane torch.

You can certainly plan to redo your first. It does take some finessing

I played with hand torch last year but mine didn’t come out that nice.

It takes practice. I found that it is best is to heat a small area a little and move way then come back to it so you don’t overheat it. I usually start at the bottom because heat will move up the material and work it back and forth. Make sure you hang whatever in the air not laying on a surface.

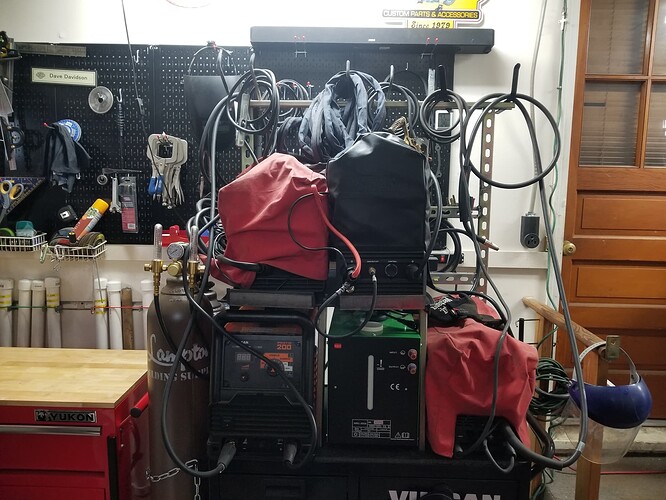

Has anyone made or have plans to make a double stacked welding cart? I’ve got a MIG and TIG that are on separate carts, the bolt together $100 ones, but I’d like to consolidate them as they’re flimsy and taking up too much floor space.

Here is one.

This extra example is not a dual but it is one i made from a 27" tool box

Modified the harbor freight cart. I have a Lincoln 210mp, Lincoln plasma cutter, Vulcan protig and Everlast 255ext with water cooler. Quick, easy, just not all that refined…but it works for me.

I bet that weighs a ton.