Now that’s funny and you better pick up the pace

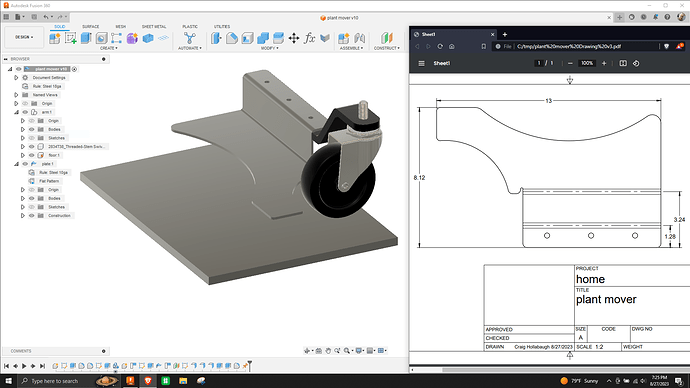

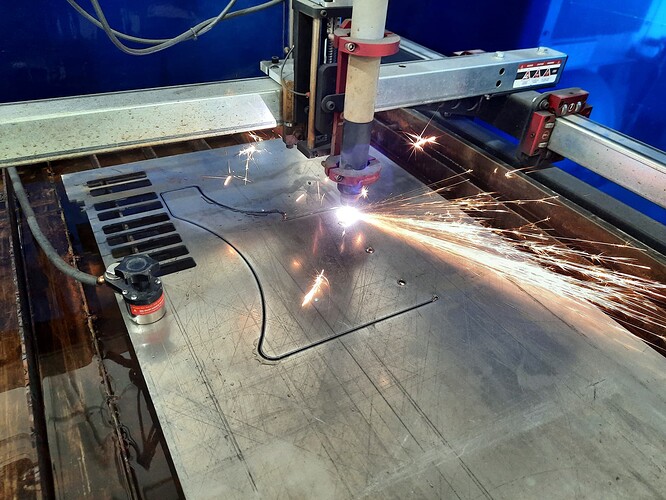

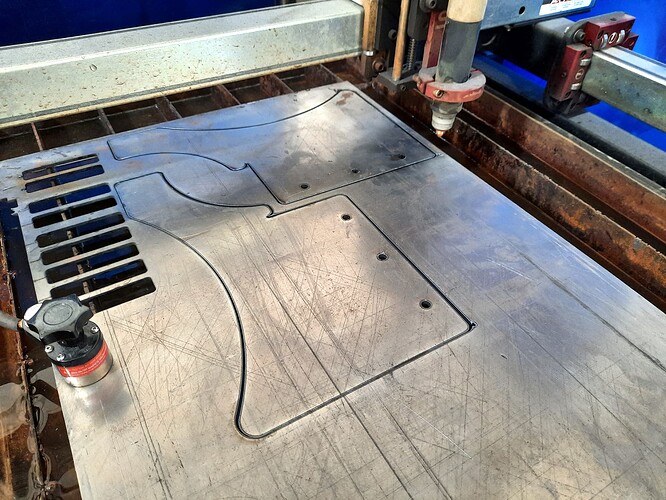

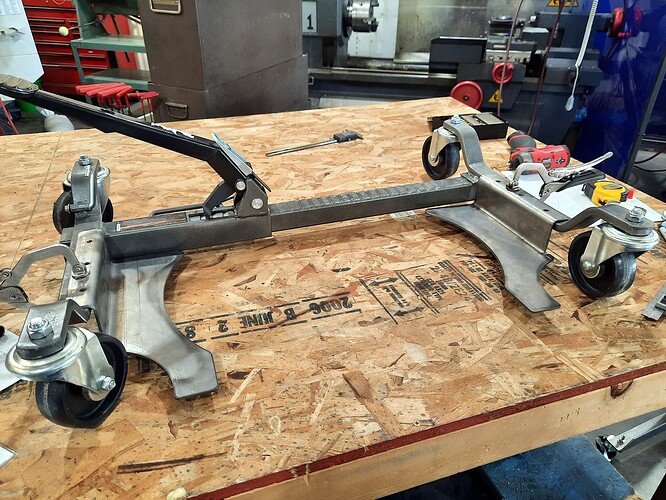

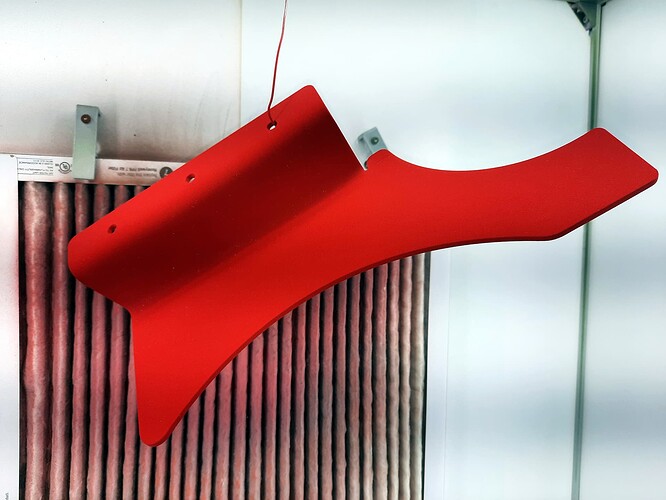

Found an open-box wheel dolly at Harbor Freight today. Had a different plan for it. Did some modeling, cutting (virtually dross free 10ga), bending, powder coating (Hot Coat Metallic Red) and assembly. Now I have an super sturdy, low to the ground, easy to roll 4in wheel platform for moving pots around the garden and house.

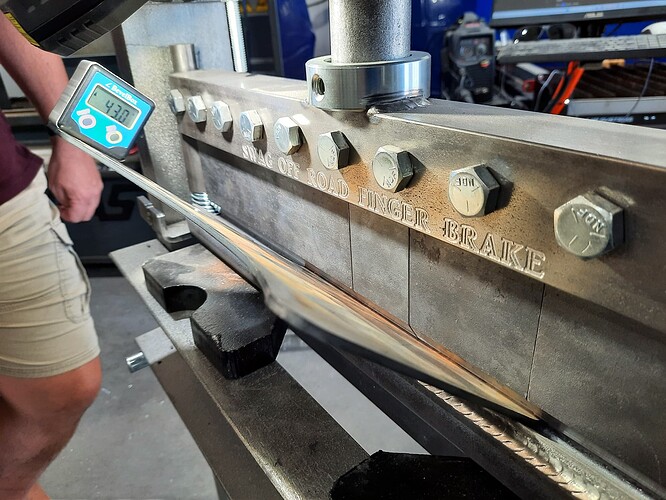

How thick have you bent with you Swag brake and how wide is it?

I have bent much with it, but it bent this 10ga without a problem.

Dee-cent!! Maybe a good next would be a Samsquanch !!! Or, Conky… ![]()

I’m using a air-assist jack on a 20 ton HF press

Very cleaver my friend.

Didn’t I see a Haas VMC in the back corner of your shop once?

If you are ever running that take some pics, would be cool to see.

holy crap!!!

base price of $58,000… ![]()

![]()

![]()

my 2 cars do not even add up to that…

nice…tool…

Very nice. Been contemplating one myself. It’s a perfect size. My friend has a VF5 in his two bay garage. It takes up most of it. He makes these small aluminum parts for the the government.

He can make 8 or 9 per day @ $400 ea.

They even give him the GCode program.

2 or 3 days a week. Very lucrative…

It’s in our shop for now, we can use it but its not ours. Hopefully we can just take over the payments and keep it.

I hope it works out for you. What a find…

We have a lot of other equipment. Haas TL1 lathe, UR5 cobot, ABB 6-axis robot arm, 120W CO2 and 40W fiber laser, 8’x4’ Avid router, knee mill with automation, giant manual lathe, optical comparator, 2 Bambu X1 Carbons, resin printer, 48" box and pan, Evolution metal chop saw, Powermatic vertical band saw, scroll compressor, welders, sander, grinders, etc. Three of us old fellers share the space and tooling. @toolboy

For those who powder coat their Crossfire cut creations, here’s a little goodie that works great. Clip a $7 HF flashlight to your gun.

https://www.printables.com/model/567640-eastwood-pc-gun-braun-led-pen-light-mount

wish I had friends like that…most of mine just want stuff for free

If you wrote a book about all this stuff, how you came across it, how you guys got together, your back grounds, what each of you excel at. Sounds like the ultimate set up or at least will have at some point.

Very interesting thanks for posting

Thanks, I’ll take that as a compliment. One of the old guys I spoke of is the director of engineering here - https://youtu.be/LfbsVl9yyOk?si=lEDzlLZMpymdMnCH. He grew up machining high end fishing reels. Here’s a really old version - https://www.youtube.com/watch?v=5JK0GxwrN1A

I’m no flunkie either - https://www.linkedin.com/in/craighollabaugh/details/experience/

Together, along with 3 to 4 others here locally, we’re quite a team.

Craig

Thank you for taking the time to post very cool stuff. What a treat that your Granddaughter has access to so many skilled people.

I watched both videos and was amazed at what goes into a fly reel

Ps you last link did not work and that’s the one I want to see