What is a cartridge adapter?

Have you checked kerfs to what they advertise with the sync cartridges?

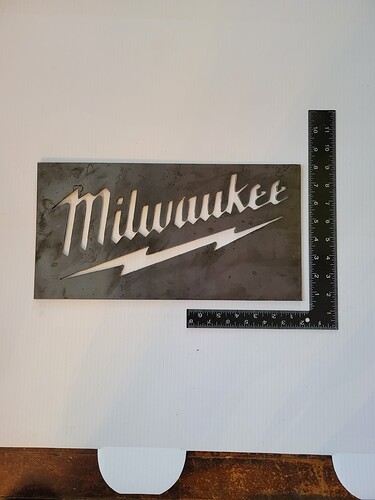

I cut out 3 each of these today in 18 gauge. Came out pretty good. These are for people who’ve seen the few I have given away to family and friends.

I am not in the sign business, but I can see how easy it would be to get sucked into it, at least on the small scale. I also see how there is a lot to consider before jumping in, as far as ability to make it worth the effort. Right now, I am just having fun learning.

People really like that “Porch” sign, and where I live there are a lot of deer hunters, so the other one is a natural. In space above the “Eat” I have added last names for a few people.

What’s the advantage of the Hypertherm synch cartridges over the original that fit your torch?

I was hoping to do some test cuts today to answer your question: lots of software needed updating and I didn’t get there today. I don’t expect to meet optimal performance without using a Sync machine, but it’ll be close once I get the right parameters down. I’ve got a whole bunch of different jobs on the bench: tool steel rods, structural bar, aluminum plate, aluminum sheet, etc. Even some hardness testing on the tool steel stuff for DOE. I’ll be sure to share results, and even do a comparison between the cartridge and regular consumables. I don’t have any 777 electrodes, but if I can’t get the performance out of what I’ve got, that’ll be next.

I saw a handy tip on YouTube yesterday and tried it out today. Guy was using a brick chisel to knock of backside dross. His video was totally bogus as all his shop equipment was brand new.

But, I tried it today and that tip definitely will save some flap disk wheels. I tried flipping the bevel both ways and it worked best for me with the bevel against the metal surface vs what I show in this pic. I paid $18 at Lowes. It took of 90% of the dross I had today.

Supposed to have extended life. Not as worried about simplicity, but it’s definitely easier to assemble. If the processes prove out, I’m handing off operations to someone who doesn’t know anything about plasma cutters. Cartridge makes it a lot easier to train the dude who’s not the brightest bulb on the Christmas tree.

Also expecting my power supply is near the end of it’s life: It’s been rebuilt twice and still has hiccups. If I get something new, it’ll be a sync, so I don’t mind future-proofing my consumables drawer.

Would love to see the difference. I know it is insane what they advertise fore the fine cut cartridge. I bought the last non sync i could find kinda wanted to watch the new tech first… I use the copper plus electrodes a lot. I burn around 500 parts out of 1/4 sheet metal with 1500 pierces. Still has cutting left but I normally change them out.

Damn!

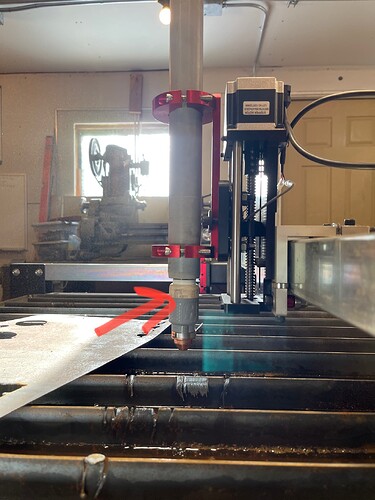

Only tried to cut one sign today. Got to the last few cuts and for unexplained reasons the torch did not fire on 4 cuts in a row. Then, it fired for the last and longest cut, which was the perimeter of the sign. That cut was perfect.

No errors just didn’t fire on those 4 cuts just before the perimeter cut. Small oval holes just like the roughly 40 or so it had already cut and one letter (“I”). Air pressure was good, consumables relatively new, all other cuts look perfect.

As you can see in pic 2, it made some minor arc/burn marks, but no penetration. Those should have been the ovals just like the others around the perimeter. To the right of the first mark, you can see where it hit for the “I”.

Very frustrating.

Sometimes running too low of an air pressure will cause misfires like that.

the blowback not initiating your arc quick enough.

Thanks. I had walked away and wasn’t watching at the exact moment, but I heard the misfires and I know the compressor wasn’t running. Also, I recently bumped it to 75psi on the advice of several on the forum. I am suspicious of wet air as I have never dropped enough money to fully combat it.

I have two oil/water filters(1@ tank outlet then 1@ at table leg), then a silica bead filter, then a final cartridge filter at the cutter inlet. Two of them have drains that purge when the pressure gets down to about 10psi. I guess that’s just not gonna “cut it” (haha). I also open my tank valve every session. Usually 2-3 tablespoons of water in the bottom of the tank. My air only travels through about 10-12 feet of line tank to cutter.

I’m going to try to save this one since my last three sign attempts all ended in scrap! I know time wise it doesn’t pay to do so, but it’s a matter or stubbornness at this point ![]()

I know a tool fan who would love to have that file. He just placed an order for a Langmuir table.

Did you put this one to FileShare? It would be a great one for him to try as a first project.

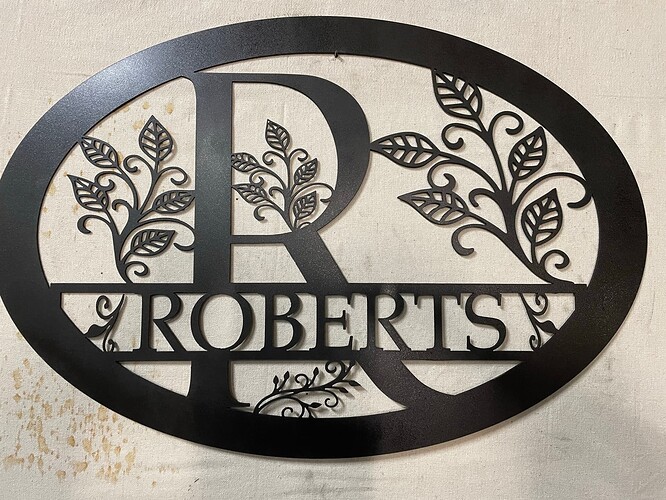

Nice looking work.

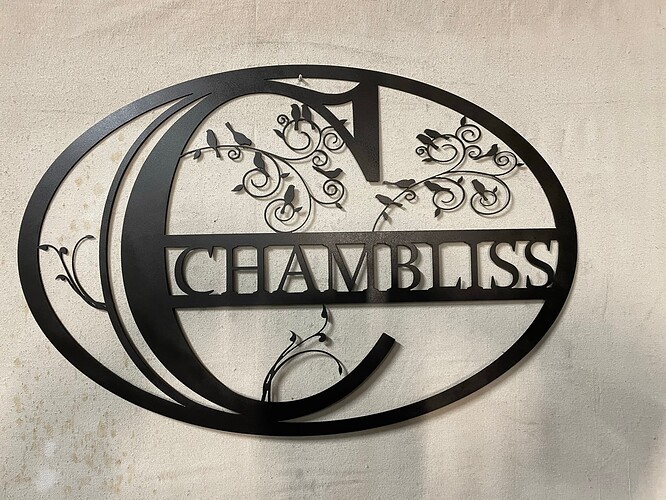

Wow, that’s nicer than the basic one I made. Nice work!

The feathers and the rope detail are something I would have been hesitant to try for fear of bad lead-in/out cuts.

What kind of backdrop are you planning?