Love the cable tray idea.

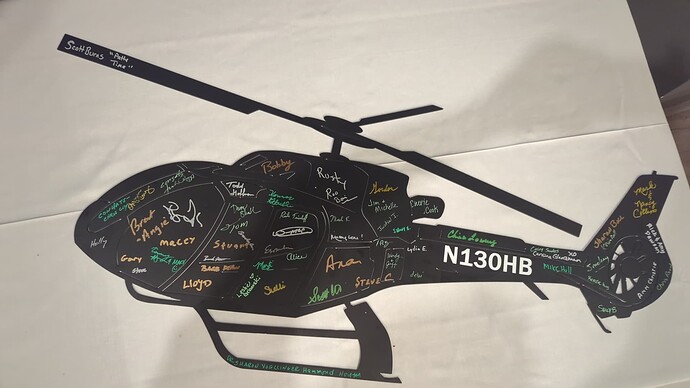

I think I have shared this Helicopter before but wanted to share how they are being used at my work. People are ordering them from me and taking them to the retirement parties and having everyone sign them

Man, that’s awesome. Slap one of those in a glass case and the retiree has got a great wall hanger.

I really like the detail imparted by the single line (open loop) cuts.

So did the customer really want 1869 as the date??? Your posting in the Font thread had 1896.

Dam…… good catch. 1869 is what I cut and 1869 is correct. Geesh that would have been horrible. Sign needed Monday and I work a 24 hour shift tomorrow so that would have been bad.

Nice. What did you use to glue(?) the bolt head to the face of the sign? I use two-part epoxy but have occasionally had issues with it snapping off even though I rough the surfaces prior to gluing.

I’d recommend Locktite 680. That goo is evil.

Is that the green thread locker? That penetrates threads very well and doesn’t give them back - without a torch, that is…

Exactly, otherwise permanent until you apply a lot of heat.

“Bushings are a man’s best friend,” is what the great wise one said once or twice. Spacers work the same.

The reason I bring it up…

- I never got why people used so many nuts when bushings are available.

- and…secondly, bolt spacers exist too.

In my reference designing, bushings and/or spacers rule the day over so many nuts.

I have an older laser module and the people that assembled it seemed to like nuts over bushings/spacers. So, just a heads up here.

I reference this laser as much as possible since I was short shafted on the deal. Since the inception of FSlaser, they have been more than helpful and forgiving. In the same light, their assembly technicians would be better off with bushings instead of 15 nuts. It makes for a more formal, well educated fit in my reckoning builds.

Seth

P.S. All in all, that sign is a thing of beauty. Please do not ruin it by placing 20 nuts on it without one single bushing and/or bolt spacer. This is something I thought was fan-tan-tastic about Langmuir Systems and their build process for the user, e.g. they had the bolt spacers! Anyway, okay. I just wanted to give my two cents on this effort on such a well made sign that obviously took some time and effort on your part.

I did not glue them nor loctite. The customer needed to paint it. I ended up cutting the screws to the right length and capping the screws with stainless steel acorn nuts.

How do you nest all that to cut at one time. Looks like a lot of post work!

@3Twenty8 welcome to The forum.

I use the arrange function in Autodesk fusion after which I might juggle some things around a bit. Sometimes I may even manually arrange depending on the situation. Another option I’ve used in the past is deepnest.io

It’s all a lot of work. ![]()

Very nice! Did you install?

No the farmer painted it and installed it.

thats a new one for me!![]()

Makes sense, was for a farmer!

English as a 3rd language….. Happy I can provide a laugh