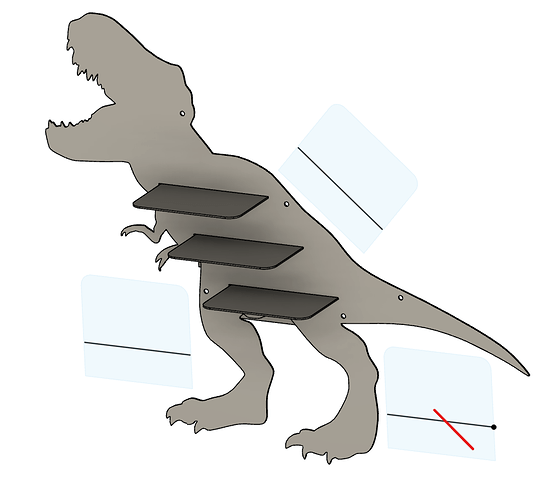

I did a quick demo on making a T-Rex wall shelf out of 16ga steel. You may want to reposition the holes. I added sheet metal and few other features in the video so it’s not just basic 2D design. I don’t plan on cutting this but would make a cool boy’s room shelf. GL and keep making cool projects and post them.

T-Rex shelf demo dxf.dxf (234.1 KB)