I protect my pan with a thiick layer of black sludge lol.

On my Crossfire, at the bottom of my pan sits a piece of 1/16" SS sheet cut to fit, it is lifted off the bottom of the pan by a bunch of spaced out 3/8 SS nuts so water can flow in and out around the sheet. This acts as a “Blast-shield” at the bottom. Has been there from inception and works great, without any issues.

This kind of “sacrificial” heat absorber is a great idea, just make sure that air bubbles that get trapped under it have places to exit (maybe a slight ^ v ^ v bend pattern with slits cut at the top of the ^'s?) such that you always have water beneath it to attenuate the plasma. The issue is, it doesn’t protect the seam/flange of the OEM 2 pan water table without making the water depth shallower there.

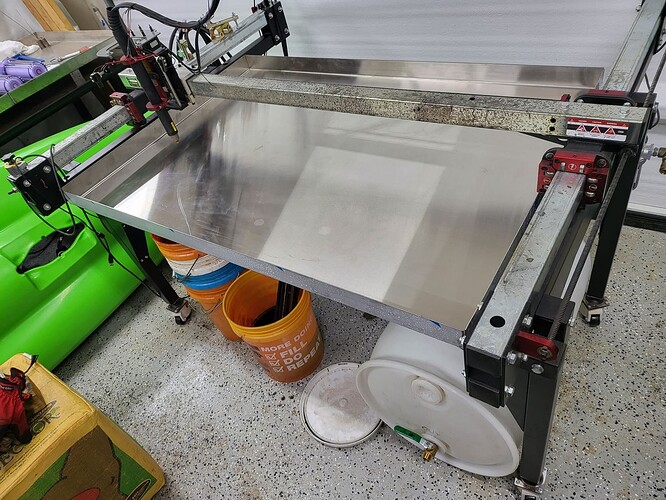

I followed in the footsteps of BD, making my own single volume pan from 16ga stainless with a single centralized drain. Made the side flanges as tall as permissible without raising the Y axis. I don’t do much work out in my garage during the blazing summers here in SE TX (because health things), so I wanted a way to reliably and quickly drain and refill my table for cleaning (and anti-sludge/algae/grossness reasons).

I’ve posted this in a couple different threads, but my reservoir / filter / pump system:

I also did a liner in my pan which helped, but those air bubbles are a definite thing. I hear air bubbles for quite a while after filling. My issue was the seam, slow 65 amp passes in 1/2" caused issues. I’m in the process of building a single piece table with more depth, which involves new risers, but I’m hoping it’ll make it so I can run 65 amps more often.

It seems as soon as I replaced my slats with the v type pointed slats, I have had issues with the seam. All the sealant is blowing out and the seam has a 1/4” gap in one area where most of my cutting is done. Headed to my local fab shop next week to get a 14 ga one piece steel tray made!

2.25 inches deep if you want to make it the same size. Any deeper, it will hit the Y-axis trolleys.

I made mine out of 11 ga stainless years ago.

Oversize it on length and width. At least 42 inches front to back. Cuts down on the splashout.