I don’t want to start an argument.

And I fully plan to proceed with the EMI mitigation strategies that have been presented.

BUT

I wanted to give a brief synopsis of my video teleconference with Langmuir’s tech support this evening, and a bit of a lightbulb moment that I had afterwards, at dinner.

So, basically, Langmuir connected into my laptop while I ran a bunch of cuts this evening, and of course, this time we couldn’t replicate the freezing issues I had experience just an hour prior (see video in the post above).

My wifi signal was too weak in the garage, so I had to use my mobile hot spot. Plus I was on the phone, plus I had my laptop plugged in. And everything worked perfectly.

I asked a BUNCH of questions. The tech didn’t think my Primeweld plasma cutter was the issue. He didn’t think my coiled up work lead was the issue (though he did suggest I uncoil it, and even better shorten it).

I asked about EMI, and his suggestion was that I try to pay attention to what’s happening when I’m having the freezing issues. His words: “is your neighbor using a grinder, is your wife doing laundry”. This is what, in the literary world, we refer to as “foreshadowing”.

The tech also said that people have issues with FireControl freezing often, and for a TON of different reasons. And he said that a common issue is actually incompatibility with the computer graphics card, especially when issues only present during complex geometry (“G3 moves”). He couldn’t give me definitive information about which graphics cards are compatible and which are not; high end cards seem to have more issues than basic equipment, and he thought my graphics card was probably fine.

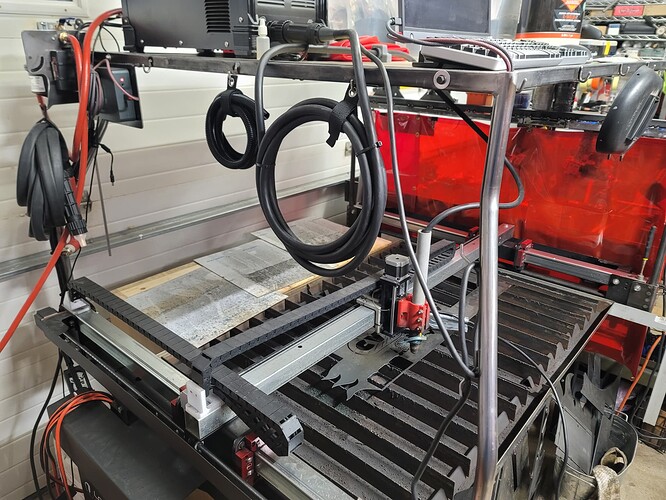

Anyway, at the end of the day, we didn’t really get anywhere. And I still need to do some EMI mitigation best practices, move my Primeweld as far away as possible, and ground my table.

BUT

When I came in for dinner I asked my wife if she was doing any laundry today…

We determined that she was running the dryer when I had FireControl freeze up, and she was done by the time I got on the phone with Langmuir. And she’s pretty sure she was running the dryer around the same time I had the big failure on Sunday.

I’m not going to say that’s it. But it’s certainly an outside of the box thing to look into.