When creating a toolpath, if the dimension of the item is somewhere under an inch it does not generate. Even if I set leadin and leadin radius to zero, it still will not create the toolpath. I also have tried assigning entry positions in the largest area of the item and it doesn’t help. Does anyone have any ideas.

2021-09-06T05:00:00Z

Post your file.

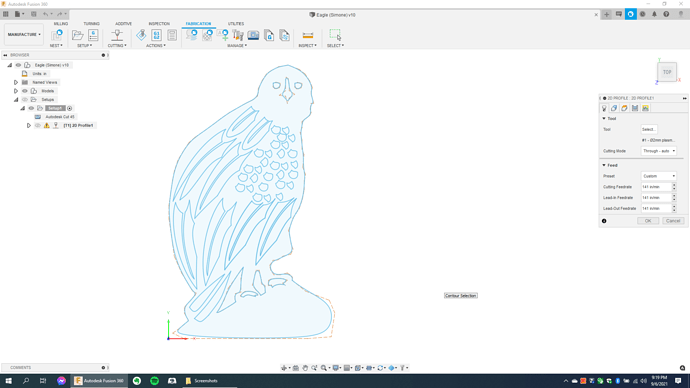

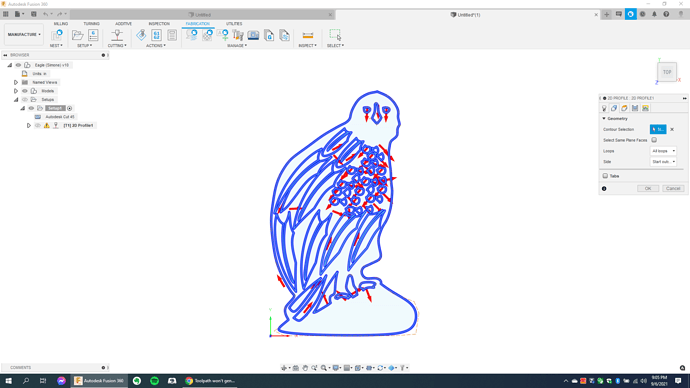

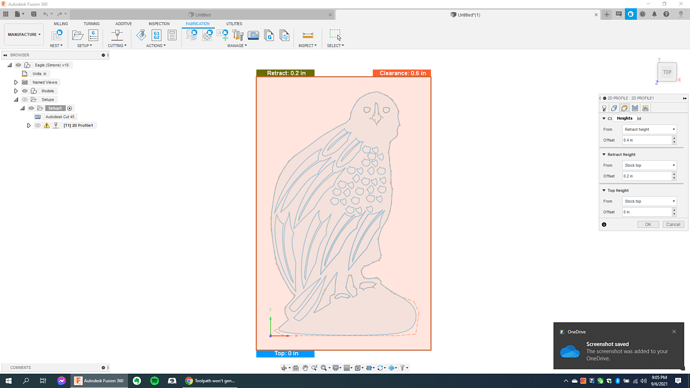

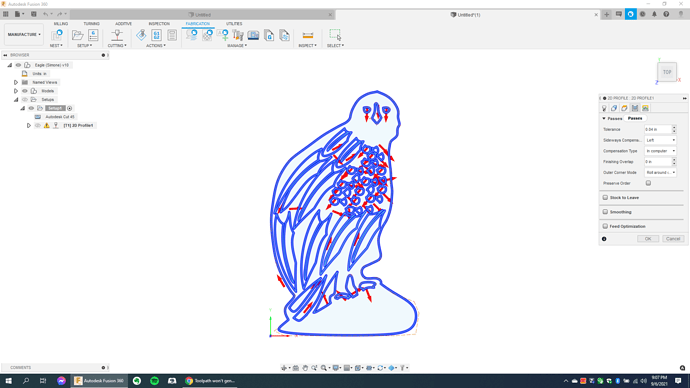

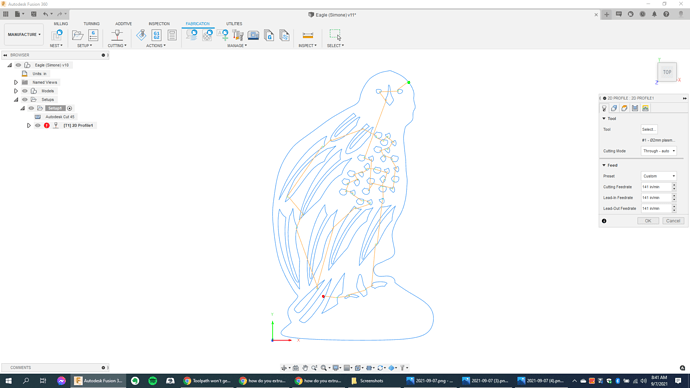

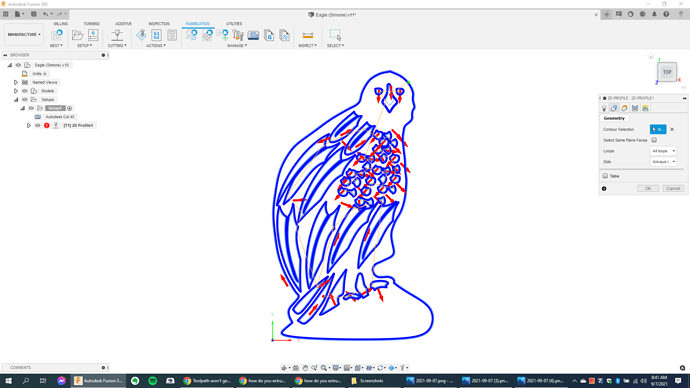

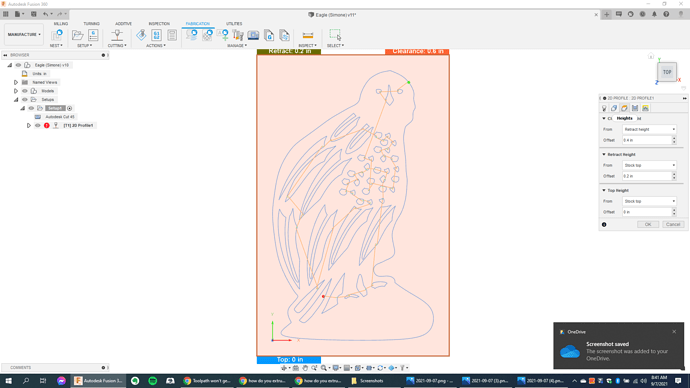

Or post screenshots of some of the settings in your 2D profile menu.

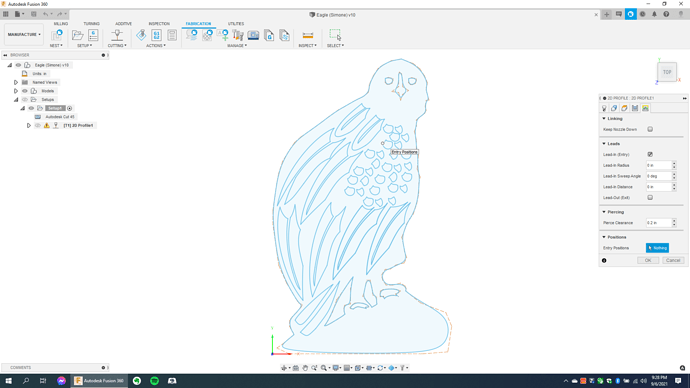

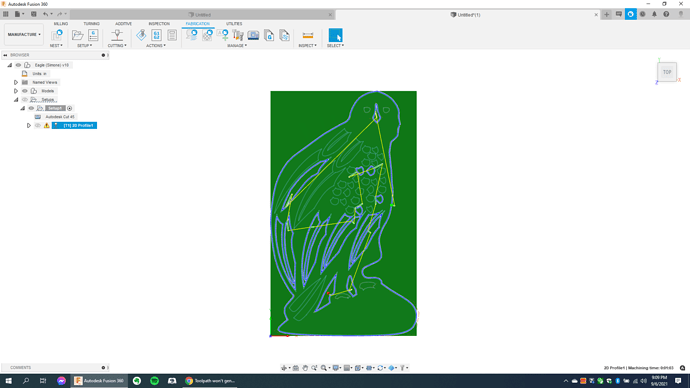

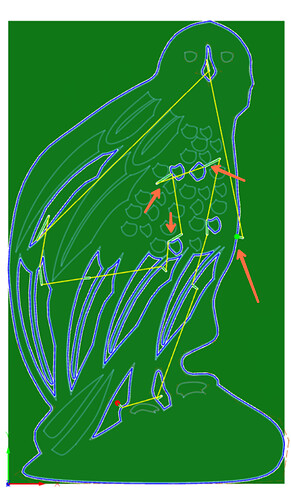

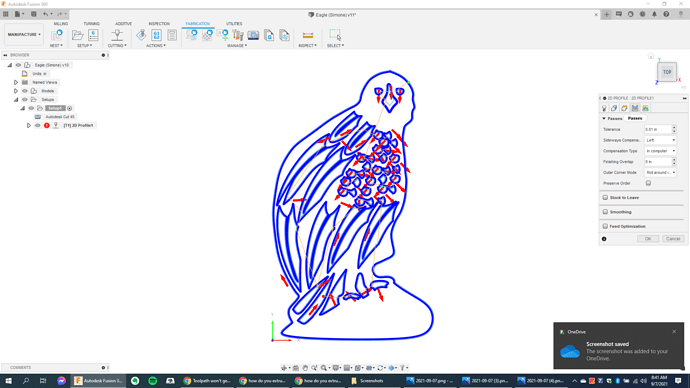

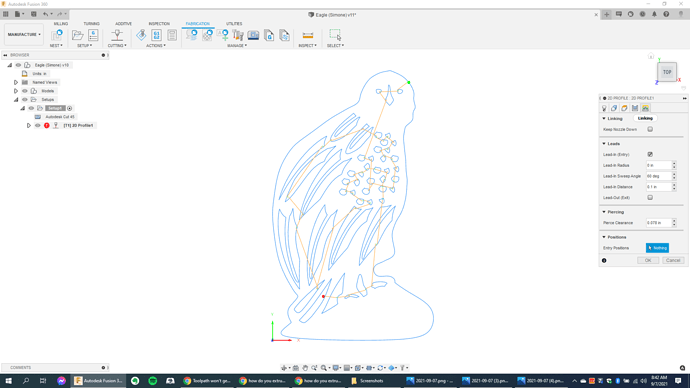

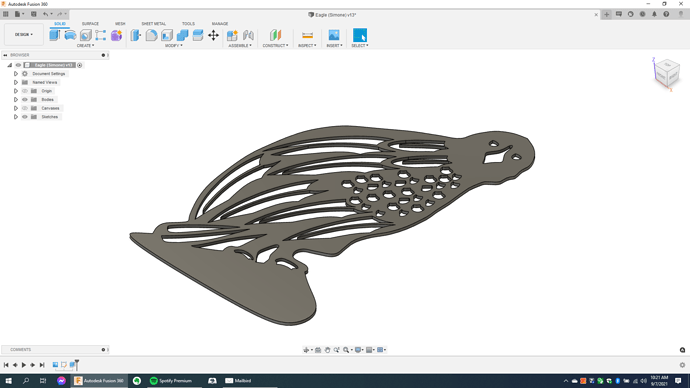

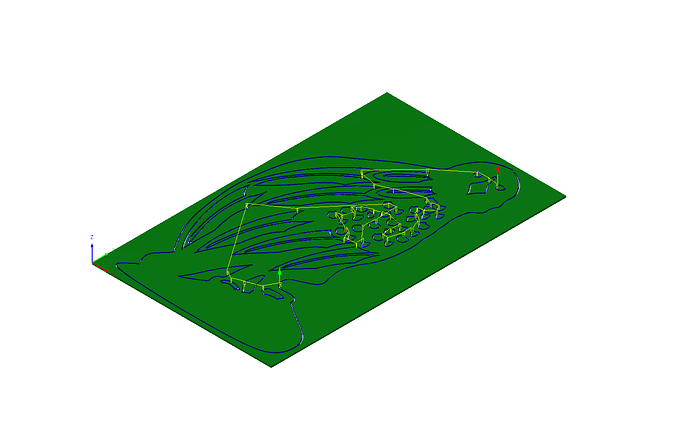

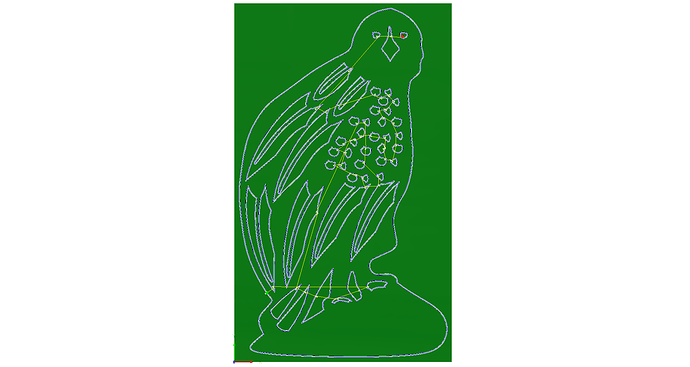

It wouldn’t let me post the file (F3D) but here are some screenshots. This has become very frustrating because it won’t let me do anything small.

I posted the pictures in order.

Hopefully you can see something I am doing wrong.

Thank you very much

Heinz

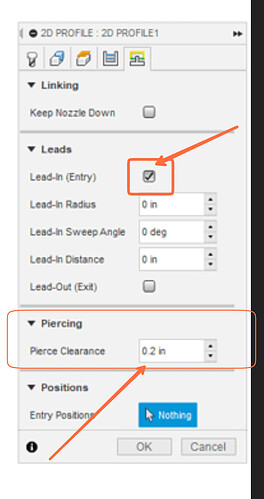

Uncheck the lead-in(entry) box.

Change Pierce clearance to .055 or .06

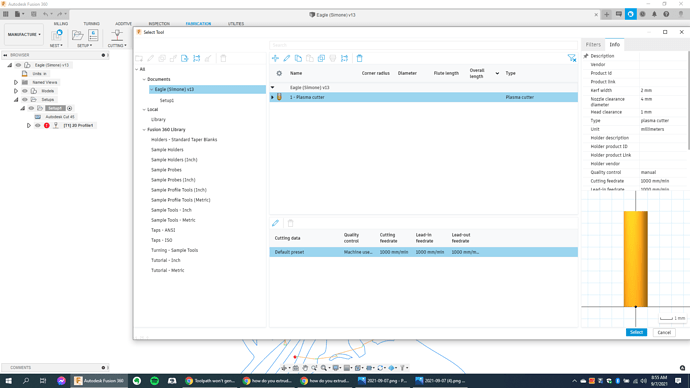

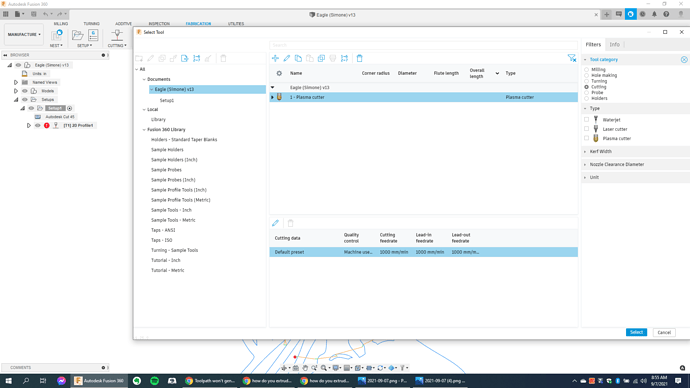

Screenshot the tool preferences as well I want to see what you have your kerf with set for.

You’re very welcome hopefully this gets you cutting.

Also I would extrude this sketch geometry so it becomes a body before moving into the manufacture space.

If you look closely your tool paths here you have some cutting on the wrong side of the line.

Developing toolpaths from bodies instead of sketched geometry gives fusion 360 the information for this not to occur.

Good Morning Sir

Thanks for the response. I still need to learn the Extrude tool. I will work on learning it.

I made the setting changes but it didn’t help.

So I went back to an earlier cutout I did and noticed some changes in those settings. I attached the screenshots from it. These settings allowed me to create the toolpaths. I also added the screenshots for the cutter.

One thing I did notice, in pic 2a it shows some arrows on the wrong side even so they are correct. When I click on them the arrows don’t move. All toolpaths show correct in pic 5a

Please let me know your thoughts.

Thanks

Heinz

Extrude your piece before navigating the manufacturer workspace. Then you do not have to worry about which side of the line anymore.

Post your DXF and I can walk you through the extruding process.

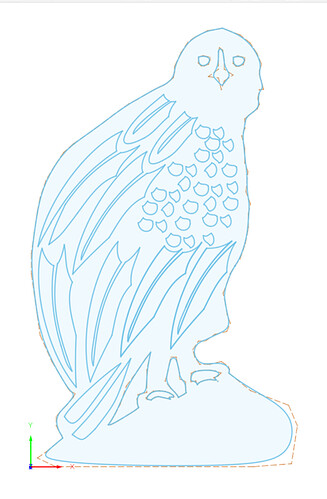

Here is my DXF file and I included a screenshot, I think I figured out the Extrude function. Let me know if there is more I need to do with it.

Thanks.

Eagle (Simone) v13.dxf (202.5 KB)

I was able to generate a tool path.

I had to add a couple lines to the feather on the back but a pretty clean file.

I will have to look at it further after work.

I really appreciate it. This has been the toughest part of learning this program.

Thanks.

Thanks for all your help.

Noob question but how does extruding it before moving to the manufacturing section to select line contouring help? I always have trouble trying to get the arrow on the inside of the inner shapes.

I have noticed the arrow problem also. If you click on the arrow it will move but not always inside the inner shape. However when you look at your lead-in it switched to whatever side it was not on. Very annoying.