Thank you!

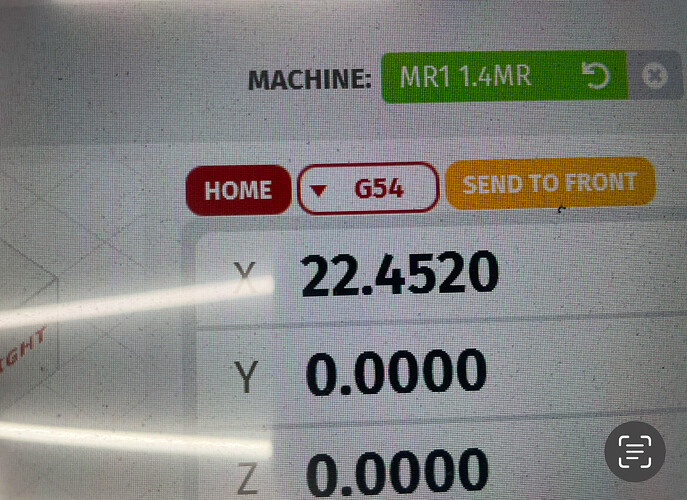

The machine homes in great now and I was starting to set the soft limits however I’m noticing that the X axis hits the hard limits about 1” from the bearing block. Is this correct? In the Langmuir video it looks like they can travel right up to the bearings. Pictures below for reference.

Are your soft limits disabled? The only hard limits I know of on the MR1 is when it runs i to itself. That looks like the soft limits are catching it well before the collision.

My thought is even with a different soft limit it won’t travel any further but I might be wrong. I am going to try and adjust the soft limits tonight.

The soft limit is/should be the amount the machine is ‘allowed’ to travel from the home position which is where the limit switches are tripped. If you aren’t able to get full travel after setting the soft limits by their instructions there may be a bug keeping it from going all the way.

I noticed the other day while machining that when I jogged the Z axis up I had the soft limit warning a couple of times before actually reaching the soft limit. I suspect that’s one of the quirks of the last software update, and hopefully it goes away in the future.

Would you happen to know what your X axis travel is from its home position as a comparison to where mine is currently stopping?

As soon as I get how me that’s what plan to do. When the X ball screw wasn’t attached I could slide the mill head full left and right so it probably is the soft limits. I will report back.

I disabled the limit switches and the soft limits were turned off and it is still stopping in the same location.

Very unusual. Do you have the lead screw nut to tight on the end? Are all the support brackets squared up? Try loosening the bolts on the end bracket to see if they are causing a bind. Run the X as far as it will go. When it stops at it usual place, loosen the lead screw support end bracket bolts to see if they snap into place.

I loosened the bolts and there was no difference. I tightened all of the bolts and tightened the coupler and the same thing happened. Honestly the mill head is over the drain at the farthest point and there is .69” from the leading edge of the mill head to the bearing block. I think that’s pretty close. I sent a video to tech support to get their input as well but it I could live with it if it is what it is.

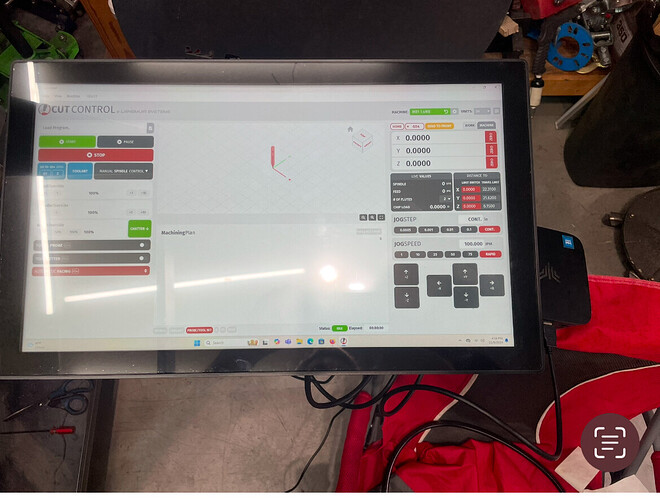

Alright looking for a little help guys. I was running the break in program on my spindle and my touch screen has gone blank. The spindle program is still running. I have powered the screen on and off, and tried a different HDMI cable but no luck. The screen will display the Langmuir logo and then say “No signal” upon restart. The power led light in the back is green but once it says “no signal” it goes red. Has any one else experienced this?

I know this is not what you want to hear. But if you are running the Langmuir mini, it’s time to upgrade.

Hopefully, you got your X movement fixed.

You are not having a good experience, are you?

Beelink Mini PC,12th Gen Intel Alder Lake-N100 up to 3.4 GHz, 16GB DDR4 RAM 500GB M.2 SSD Desktop PC, S12 Pro Mini Computers, 4K@60Hz Dual HDMI, USB3.2, WiFi 6 BT5.2, RJ45 LAN, Family-NAS/HTPC Amazon.com

I was thinking that might be the issue. I actually use a very similar mini PC to run my pro table. Once the break in is done I will put cut control on my other mini PC and swap it out. Owning other Langmuir products has taught me to be patient. It’s kind of like dating a woman with a prison record. You know there’s gonna be issues but it will probably work out in the end.

As always thanks for your quick response.

You are aware that the spindle break-in is a two-hour-long or so program. Are you sure the computer wasn’t set to go to sleep? It would wake up, but it could have locked up if you pushed too many keys and unplugging things.

The furnished computer only has 4 GB and has the latargic chip that is more cost effective than functional.

I had the sleep mode turned off. I just plugged my other PC and it works fine. Another question do you have to end the spindle break in program or does it do it automatically? I set a 2 hour time when I started the program. The time has gone off but the program is still running

It will stop when its done. You can see on the screen were it is in the process.

If only I could see my screen hahaha. It had ran for over 2 hours so I e stopped it so I could plug my other PC in. I would assume it should be fine.

It would be best if you stopped it. I believe you are running without any control. I wasn’t aware that it had not stopped—emergency shutdown or unplugging it.

Then, start from scratch.

It ran it at multiple RPMs like it did prior to the screen dying so I had assumed it was doing what it need too. I just downloaded the program again and will run it again. I also ordered a replacement PC as well