I am ordering a Cross Fire Pro. Already have a Titanium 65 in my shop. Wondering if anyone on here is using this combination with success? The Titanium 65 is not on the recommended list from Langmuir but the 45 is.

It should work just fine. You must wire it up as RAW voltage from inside the plasma cutter per the directions. To my knowledge, that machine has a 20:1 divided voltage board inside. Langmuir requirements are 50:1.

It will work without any issues on RAW voltage.

Just follow the directions on the Langmuir site.

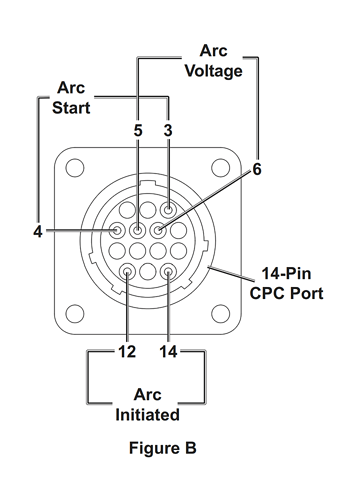

There is plenty of help here when you get to that point. This is an excerpt from the manual.

Arc Voltage

The Arc Voltage circuit is accessed through pins five and six of the 14-Pin CPC Port; it has a default arc signal ratio of 20:1. Pin five is negative and pin six is positive.

Good post. I have a new Titanium 65 wanna use it. Also have a 45. Do I just use it as hookup pics are available. ![]()

![]()

![]()

Welcome to the forum.

The search tool is useful for this… (magnifying glass in upper right)

This thread has some info on hooking up the 65. You will have to go with raw voltage inside the machine, since the divided voltage output is 20:1 and won’t work with the Langmuir THC.

I located the CPC port connector for the New Model Titanium 65. Now to put the appropriate pins in the plug. Per the HF instruction book looking at using the “Arc Start” and the “Arc Voltage” spots. Anyone out there have any ideas if I am on the right track?

Best wishes. Thanks for helping

Raw Voltage. The machine has the wrong divided voltage output @20:1. Your table needs 50:1. You can use the CNC port for your torch switch though.

I believe the pins 3 & 4 are what you want.

Maybe @mechanic416 can chime in on this one.

That will work. Right now I have cables hooked up inside the machine I hope are raw voltage. The 90 degree cables that plug into the THC control box. Any advice to make sure these cables are connected properly inside or do I roll the dice?

Thanks.

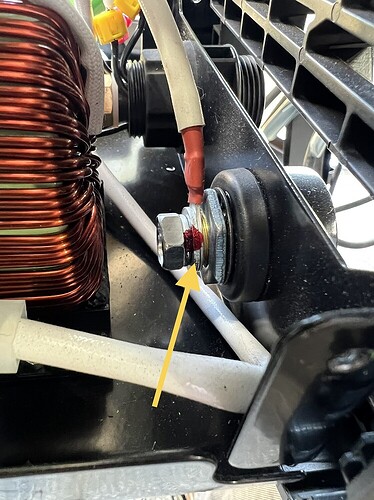

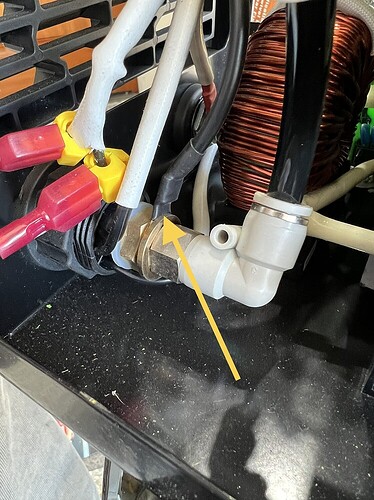

Red to the work clamp… Black to the torch.

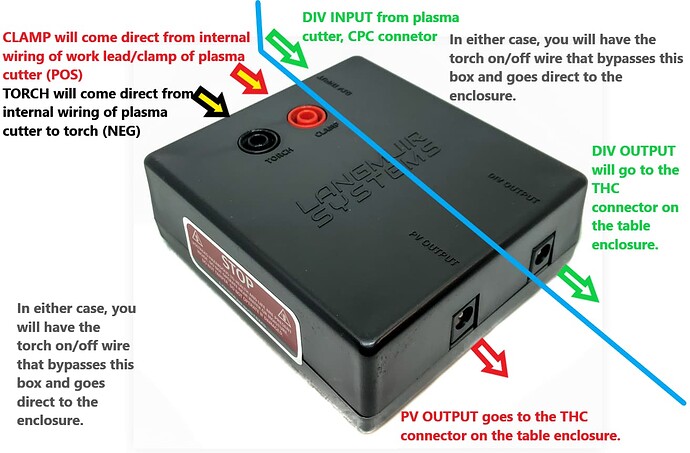

Hook it up just like this. Pay attention to the table connection in the picture. No connections right of the blue line.

In this picture you can also see the torch on/off connections just above the torch connector bolt inside. Black wire torch. Red wire to work clamp.

The torch switch connection is just a switch, so the wire hookup does not matter.

Thanks. Will give a check where I am at and proceed as needed. Great.

So. I did as you advised inside the cutter to get raw power. One lead to the clamp. The other to the torch power. Those leads on the banana plugs into the small box. One clamp. One Torch. Then on the CNC port with the correct plug. Pins 3 and 4 arc start on the wire/pigtail plug going into the DIV input on the small box. Now the other side. The patch cord from the table box labeled Torch into the PV output ![]() . Now the other plug in cable goes ?? Only the DIV Port has nothing in it. Questioning if I am there or this last plug in cord is used. Still wanna not ruin some good equipment. Thanks for your patience with me.

. Now the other plug in cable goes ?? Only the DIV Port has nothing in it. Questioning if I am there or this last plug in cord is used. Still wanna not ruin some good equipment. Thanks for your patience with me. ![]()

![]()

PV to the THC aircraft connection on the control box. The Torch on/off to pins on the CNC port.

No connections to divided voltage pins. Only the banana plugs to inside the plasma cutter. Black torch/ Red work clamp. No divided voltage. Pins 3 and 4 to torch on off on control box.

Nothing connects on the right side of the blue line in the picture.

Well thats just awesome. We got it right. If you would like some Oregon Hazelnuts shipped to you shoot me an address and I will get it done. Tremendous help. Thanks.

No thanks, on the nuts. Did it actually cut something? Send us a picture.

In the next couple days. Moved the table for a bit. Had to get a tractor in the shop. For sure on pictures. Thanks.