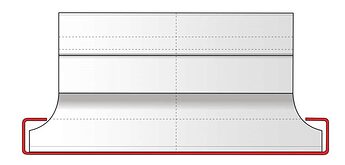

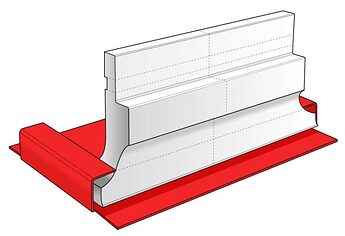

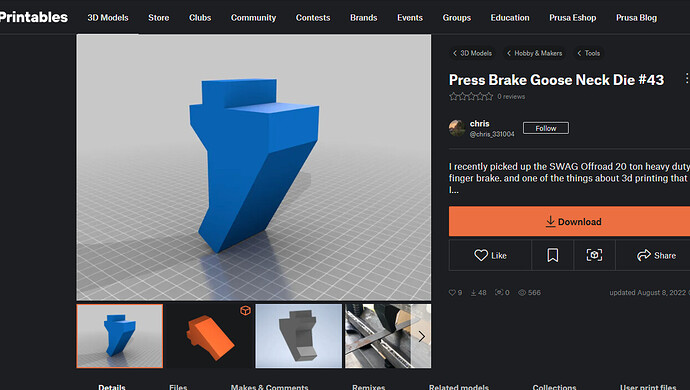

I can confirm that 3d printed dies with 100% infill have no issues bending 16ga steel in press brake. I made a gooseneck and v nose die this weekend as test since I already had the template from when I cut some out of steel this last summer. I have swag off-road finger setup and this is solid backup for any odd ball dies you might need in future if you have 3d printer.

what did you use for Filament?

I just had a friend make a couple of dies for a very specialized press I have and he used PETG.

It was between that and PLA. I have yet to try them.

I will post pics and post how they work once I get them.

PETG and make sure he did 100% infill. You’ll know because they’ll feel solid.

quick video -

It was 100% infill, I will see if it will work, these are totally different than Press brake dies, so who knows

There is a good YouTube video where a guy tests 3d printed dies in his brake. It’s very promising. Was always gonna have a buddy print me dies but then I started hunting auctions. We’ve got a pretty good auction company in the area that just does welding and machine shop auctions. I’ve bought regular dies, punches, gooseneck punches, and a big section of 4 way dies. Was bidding on a nice set of 3.5" dies but they cancelled the auction part way through. Those would have worked with both 3/8 and 1/2 steel.

Wondering what material these dies and punches are made from and are they hardned in any way, and if so what has been done?

I’m sure they are tool steel. Probably 63 Rockwell hardness. I would assume…

One question that I’d want to know if there are any plans for flattening dies for hemming? I make a lot of parts and need the combination of an acute die and flattening to make doors and draws for cabinets.

This is the tooling we are looking to purchasing with our Titan order.

Standard Punch #2 8" @ $74.95 x 4 + 1" @$9.95

Gooseneck Punch #4 8" @ $69.95 x 4 + 1" @$9.95

=$599.50

Standard 4-Way Die #6 8" @ 74.95 x 2 16" @ 149.95 +1"@$14.95

Acute Die #3 8" @ 84.95 x 2 16" @ 169.95 +1"@$14.95

=$669.70

What are you all considering for a starter tooling set with your order?

One of the best things I did with my homemade brake was to buy long chunks of die and then cut them down as needed. I do a lot of bent 14g so I picked up an 8’ chunk of .625 opening used die in perfect condition for $106 bucks. Watch your local auctions because there are definitely deals to be had for used tooling. My press isn’t that big but I just cut off chunks as I needed it.

Thanks for posting this. SUPER helpful article for a noob to tooling. I have a 48" manual finger brake, but tool selection is still hurting my brain!

Have you posted these files anywhere? I just got a 3D printer and have a lot to learn!

Donp does not come in here anymore he has moved on to laser engraving and 3d printing

I am unprepared for this. I put my order in recently for a 25T and based on the production thread I expected to get an email sometime this summer but I got the email today. I backburnered this so I have done no research.

I am self taught on almost everything and press brakes are no different so I’m kind of jumping in feet first here only knowing that a press brake will serve me well but I have no idea what punches and dies I need. please help.

For context I cut a lot of flat parts and weld them back together and I am hoping to replace a lot of welding with bending. I use everything from 14 ga to 1/4" but mostly 1/8" and 3/16" plate. sheet metal work is much more rare for me. I don’t have the budget right now to just order the whole menu so I need guidance on maximizing my productivity with the right punches and dies.

It seems like the 4 way die will handle 95% of my work and the 88deg gooseneck punch seems like an obvious choice as well but not sure if it will handle the thicker plate?

I also don’t know if I need smaller sections of dies? the smaller segments of punches makes sense to me but I don’t see why I cant just buy 2 16" dies. Is there something I’m missing here?

CNC backguage?

4 way die holder?

Thanks for any help.

I would start by checking out this thread.

The gooseneck will definitely handle thicker plate.

Thank you. I thought I had thoroughly reviewed that thread having looked at the punch and die guide and all the posts but I overlooked that buyers guide.

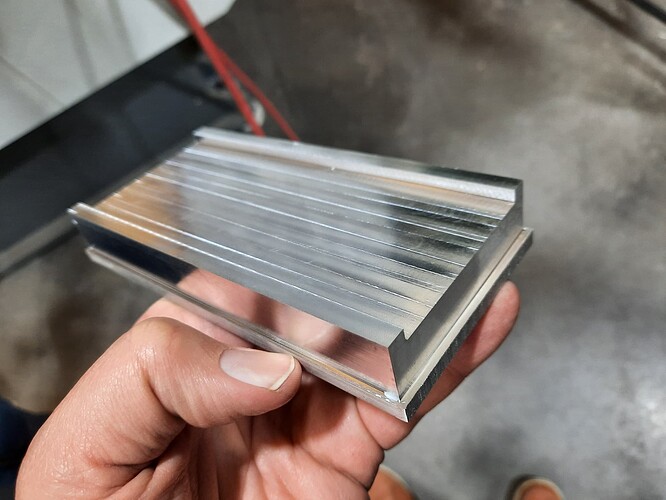

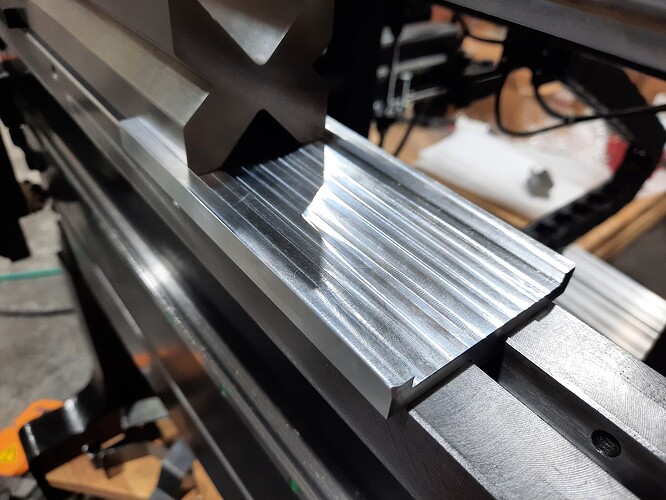

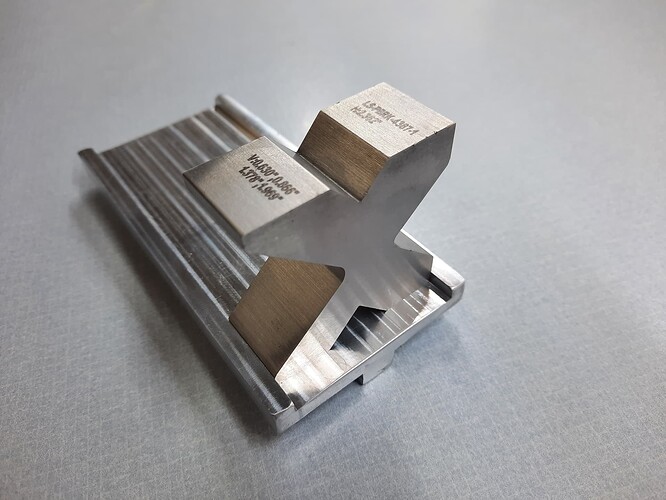

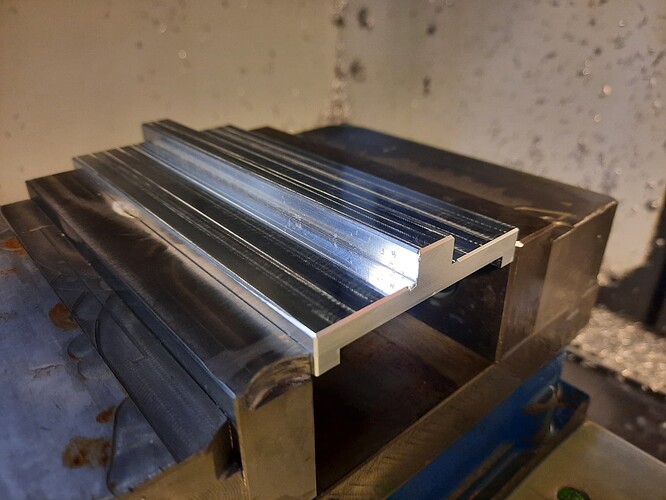

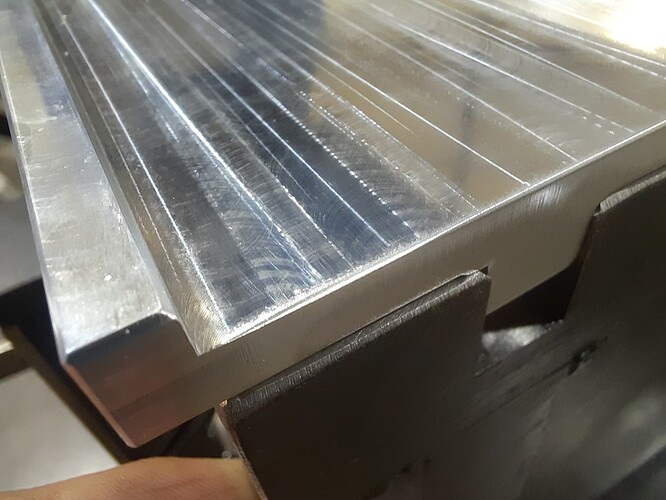

Our die risers are on backorder, we started making some today. I bought a 1x3x48" aluminum bar stock. Thanks to @Bigdaddy2166 's loaner does, took accurate measurements and milled one today.

OP1 done - Top side

We flipped it over and milled the tang.

Fit like a glove, a very tight glove.

The edges and corners are very sharp! For the remaining 4, we’re adding slight chamfers.

Levi kept an eye on us all afternoon.

I’m flying solo on our shop’s big milling machine this afternoon, HAAS DT2.

This DT2 makes beautiful chips.

We know have a full 33" of risers for our 25T thanks to the @Bigdaddy2166 loaner