Alright, I’ve been slacking on actually posting, mainly due to, idk why. So, long update.

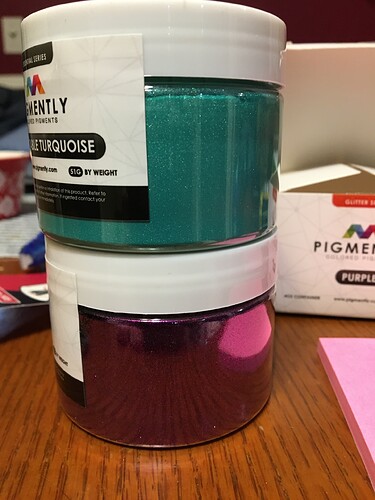

Last I had posted, I just got some glitter and the mica coloring. I started experimenting with those and timing of when to add the second set of epoxy in. It needed to be around the 2 hour mark otherwise the second color would “sink” into the first and pretty much disappear. This will change based on temps and whatnot, but basically, it needs to be super thick before adding a second color. The purple glitter I got was just that, purple glitter. I thought it was purple mixed with glitter so it didn’t quite come out how I wanted when I did the first test coaster (we’ve got lots of epoxy coasters now).

I went ahead and bought some actual purple and found that a mix ratio of .6g/oz of mica to epoxy and .3g/oz of glitter came out to a nice ratio of color and sparkle in it.

I had some stainless all thread that I mentioned I was going to use as rebar. I picked up a couple more 3’ sticks of it and made some sort of pattern with it that somewhat tensioned itself. It was still a bit too close to the anchors on the left side, so I used some safety wire to tie it all together and pull it down closer to the bottom.

My buddy came over with his mixer and we got the concrete poured. If I were to do it again, I would add some more water, but I think it went in alright. Used a touch more than the recommended starting amount, and it would hold together well when squeezed, but I think workability could have been increased a little bit still. Putting in the plate and stiffeners seemed to be a bit more challenging than it was for the Langmuir folks in the videos. The surface was a little on the rough side in a couple areas, so I scraped it pretty well before the epoxy and made sure to brush, vacuum, and blast it with air a ton before.

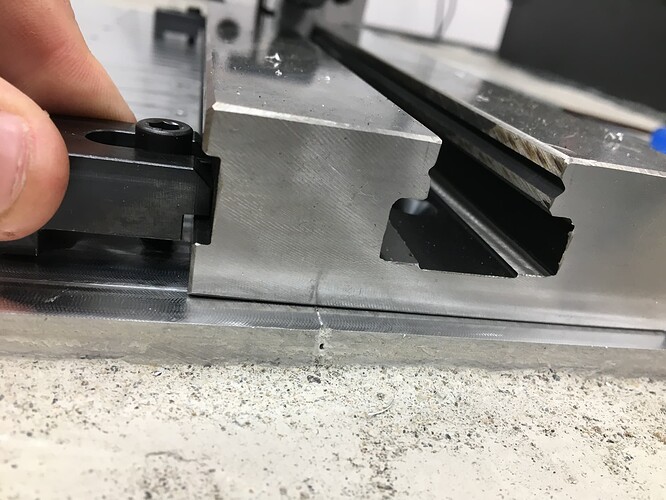

However, I knew we weren’t going to have time to epoxy stuff right away and I wanted to get a t-nut machined to make my small lathe more functional with a quick change toolpost I had gotten. I was also a bit worried about how much we were going to have to mill off because one side seemed to be pretty low on the plates and I didn’t want to over-epoxy it and then be milling a bunch of epoxy while surfacing. So we did a rough surface of the baseplate and I threw the vice on it. Unfortunately, it looks like the guys at the factory lost their bottoming tap on the day my plates were machined  The vice wouldn’t bolt down due to that, so I went and picked up a new decent quality 1/4-20 bottoming tap. However, I wanted to get it done that night, so I put a washer on the bolts, tried not to crank them down too hard, and ran them above the slots they’re supposed to sit in with fewer threads than I’d ideally like to engage. But it worked fine!

The vice wouldn’t bolt down due to that, so I went and picked up a new decent quality 1/4-20 bottoming tap. However, I wanted to get it done that night, so I put a washer on the bolts, tried not to crank them down too hard, and ran them above the slots they’re supposed to sit in with fewer threads than I’d ideally like to engage. But it worked fine!

Being the first part I had actually cut, I have to say, it was a bit nerve-racking to cut steel of an unknown hardness. On one hand, it was just a big blank with threads put in it, so good chance it was on the softer end. But due to having threads, it also could have been on the higher end of hardness. No real way to know without actual testing, so I went for a “medium hardness” and was prepared to slam the stop button. In the end, I had to modify f/s a little, but it honestly cut great. I cut it dry since I didn’t want to run coolant on the bare cement. I think it had cured a full week at that point but still didn’t want to mess with it.

After that, the lathe was 10x better to use and about 100x more repeatable. Awesome success for the first part and it was awesome to see the machine work so well on steel. My gripe with lower-priced hobbyist-level machines has always been the lack of ability to cut steel, the MR1 chomped right through it without even blinking. Nice job folks, seriously.

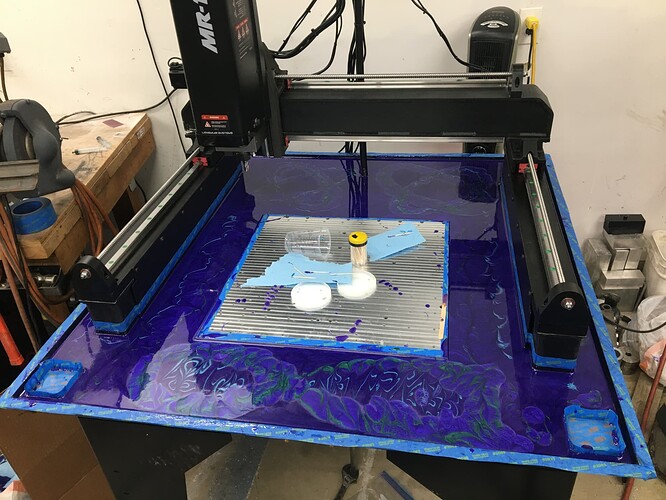

Next up was epoxy! Had a good time with this one and was decently happy with how it came out. The wife had some fun with the blue/green colors and designs and I think it ended up being pretty fun colors. Very groovy. Put a tarp and blankets over it with a couple of space heaters and walked away for a few days. I think by the time we actually put epoxy on it, it had been almost two weeks for the concrete to cure, so should have cured well! The only thing I wish I had done was put epoxy under the y-axis rails. I may try to blast some in there with a syringe like we used for the additional colors, but for right now, I sealed up the edges with some rtv.

We finished up assembly this weekend. I was gonna send an email to the Langmuir folks to get their opinion, but I had like…a lot of nod. It took two of the thick y-axis shims and an x-axis shim on the bottom to get the nod ironed out. I did get it down to about 5 tenths in the end, but that was pretty far off what the calculator was saying to do (2 x-axis shims). I did make sure that the top of the 1-2-3 blocks was completely flat in that area before measuring and it was. I had a small amount of tram as well, and I got that mostly ironed out. It was a touch under .001" when I called it there.

The little green caps didn’t fit very well on my y-axis (they fit perfectly on my x though) so I turned about 35 plugs out of acetal so I had some extras. I used the updated toolpost that the MR1 had machined the t-nut for to make plugs for the MR1 rails. Some sort of weird machining cycle of life going on there.

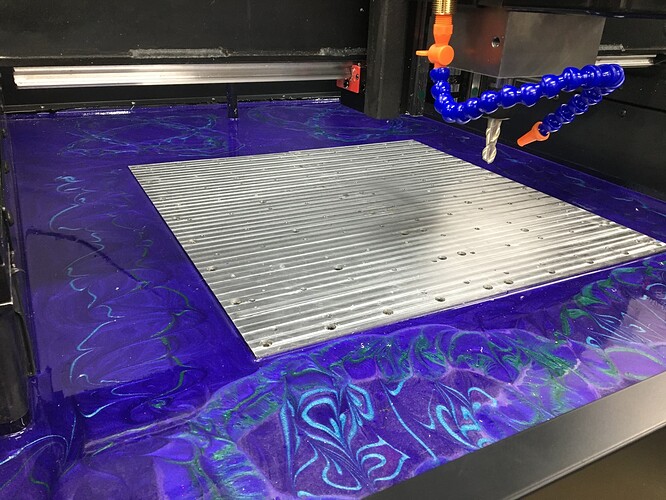

Finished getting the coolant set up, chucked up a new endmill, and did the final surface on the baseplate! Having the enclosure on sure helps with the mess lol.

Did the travel compensations, set up the tool setter, and then went to do the probe. Seemed they missed that one in QC at the factory too lol. Had somewhere around .030"+ of runout. Unless I missed it in the video (completely possible), they didn’t mention loosening the bolts on top before using the set screws. Because of that, I didn’t get much movement out of them. After messing around with it for a while, I finally tried that, and then I was able to make all the adjustments needed to get it right. Wrench is a 3/16 for those btw, luckily I did have one! Got that dialed into about 3 tenths of runout and was happy with that.

Picture limit seems to be hit, continuing in next post.