Man I just used the numbers that Langmuir showed in the demonstration. It has worked for me just fine. I have done tons of cutting on my pro table already without a single issue using those settings

Awesome. That is exactly where I started my settings in post. Thanks.

So my question is…and it may sound simple…I have the Everlast 60i and it has the CNC port in the back as shown at the top of this thread…

The connector Everlast supplies has tiny pin connectors / solder pins to fasten wire to inside the connector.

Langmuir provides a 1000v rated wire that is too big for the Everlast connector pins.

Did you connect to the pins or did you connect to another location within the Everlast?

If I remember, I got some 16g wire and soldered it to the plug, then connected the Langmuir pig tails to the 16g wire

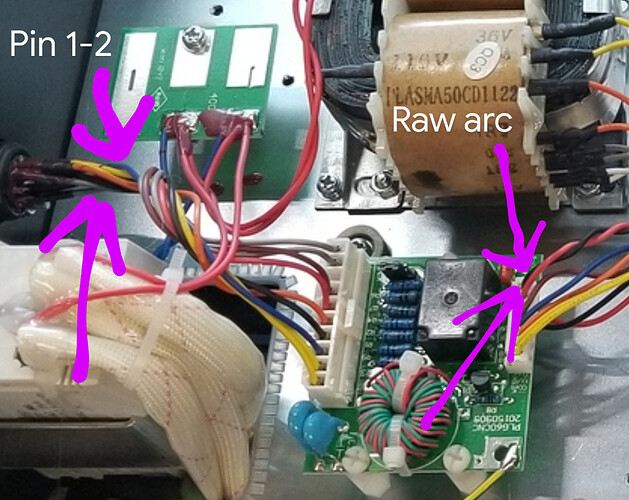

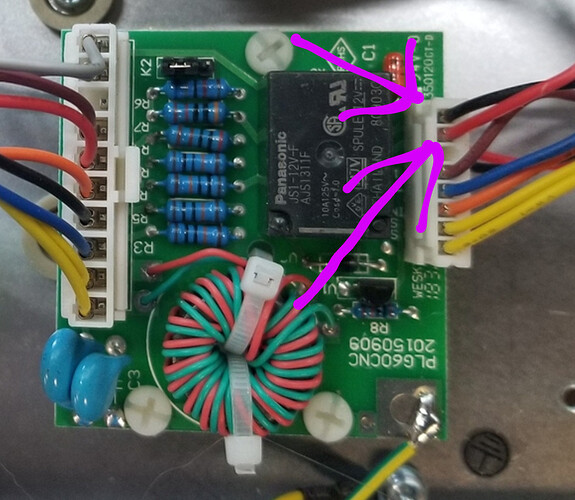

Here is what i did on that small socket pin. I opened up my 62i and tapped on the wires inside behind the socket for pin 1 and 2. Really wish Everlast had made a better socket with a adapter with wires already coming out of it. I also tapped on to raw arc inside the 62i before it goes thru the resister board and it works great, no jumpers to mess with. I never got a true reading for the other pins on the plug for raw arc. I called them and the rep told me which wires they were and he even told me to tap on to them there.

Any chance of a picture the points where you tapped in for the raw arc

No, I should have took pictures before I closed it up. But if you open yours up and send or post a picture I can tell you which ones. Or message me for my cel and I’ll walk you through it

I managed to use the connector and soldered my raw voltage lines to the pins

Are you saying that the raw voltage through the cnc board on the 62i might not work?

Yes, I never got a true reading like I did tapping into the raw inside the unit. The pin 1 and 2 work fine, the rest ain’t worth a damn imo.

well…back to the workbench and open the box again and tap into the raw voltage lines…

do you have a picture of how you came out the back/side of your Everlast with the cables supplied by LS with the banana clips on them?

jus curious if I need tro cut a new hole with a strain relief grommet or if I just come out the air vents on the front side.

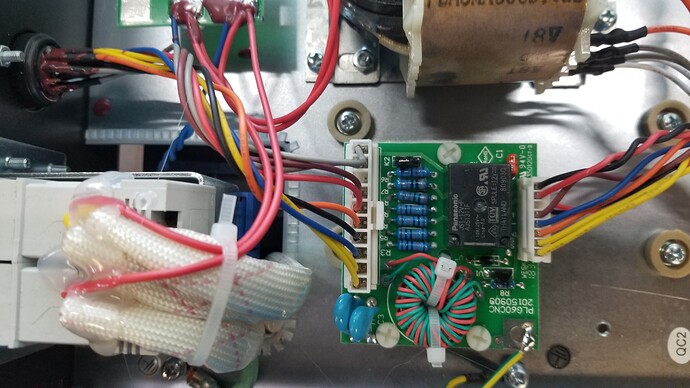

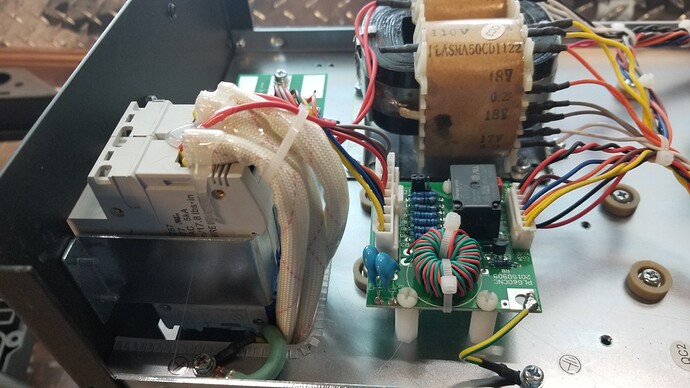

Here are the pictures inside my Everlast 80s and I’m hoping someone can detail me out where is the best place to tap the raw voltage for the THC/ LS-Pro. Lot’s of different schools of thought out there and just looking for a working solution.

thanks

jr

damn…I just screwed shut my case…note to self…take pictures all the time…but that being said…I went right to the actual terminals from the work clamp and the torch connection inside the front panel.

At the torch connection there is a great spot to actually solder your wire to,and at the clamp point I crimped a connector in the wire lead and unscrewed the work clamp screw and put on my other wire .

Then fed them out the front ofd the panel vents…and will wire tie them to the exterior.

Thanks for the pictures. For pin 1-2 trigger fire this is where I connected behind the CNC port. I just followed the wires from the pins. For the raw I tapped on them just before they went into the board. That is what Everlast recommend to do also. Hope that helps.

Also I unscrewed the CNC socket and zip tied it inside the unit and put on my own socket in the spot it was and ran the raw arc and trigger wires out the back.

Thank you for your help on this it couldn’t any easier with the edited pictures.

jr

You are welcome. I really didn’t want to open it back up. Here are the pictures from the back of my 62i. I put the wires in a cord and fed them into a box and then one set to raw box and langmuir cable to torch on/off.

Hey man, just curious what voltages you are seeing in firecontrol when your cutting?

I’ll cut something today and give you the numbers I’m getting.

Thank you. I’m using the pins on the CNC plug and am seeing 57ish volts, so I’m curious as to what the reading is where you have the wires tapped