I recently disassembled mine because I accidently loosened the wire. Now that I took the roller bearing guides loose I realized a much simpler approach is to loosen and removed one of the guide rods. I am not 100% sure that you can pull it all the way out but I would try that. Don’t scar or bend those rods and especially don’t scar where the rollers run.

I will try to find the two areas of this forum that I described the process for two other people just recently. Give me a few minutes.

Edit: Still looking for it. But basically here is how I approached it:

-

Since the roller bearings on the right are the adjustable ones, leave them alone.

-

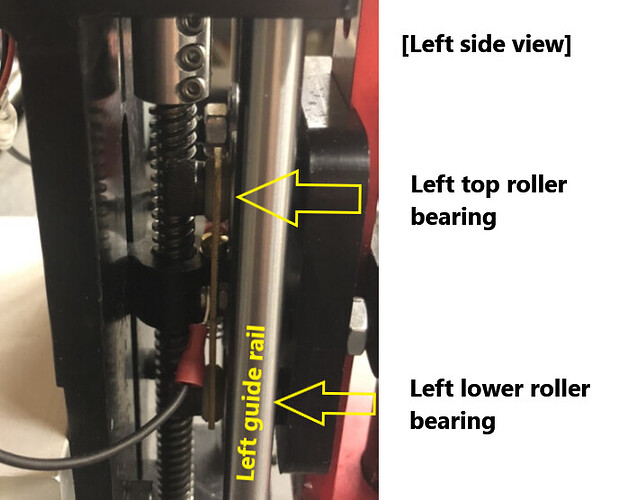

I then removed the left top bolt holding the left top roller bearing.

-

Now I loosened the bolt holding the left lower bearing to the point that is was about to fall out.

-

To really remove the z-axis carriage there is still not enough room so I loosened that rod on the left so there was some give. Be careful because this is when you will lose the spring that is part of the IHS system. Move the torch holder plate up and down and you will see the spring and how it is positioned. The upper part goes up in a hole on the bracket and the lower part rests on the nub of metal.

-

As you jiggle the carriage it will fall free, so will that spring.

-

Now you have full access to the wire connection.

-

Putting it back together…have no idea. Haven’t used it since

Just kidding.

Just kidding. -

Putting it back together is obviously the reverse but something that would have helped is to have an extra hand to stabilze the carriage while you get that left top roller guide attached again and not lose the spring 6 or 8 times in a row, like I did (might be an exaggeration…I do that sometimes).

Technically that is the the wire for the IHS (Initial height sensing). It is used to judge where the plate surface is.

Edit: I forgot to mention…all of that loosening and tightening has to be done from the backside so you need to use pliers on those machine bolt/screws. Very small movements!!!