Ok, let’s add what occurred today.

Speaking to Hypertherm, Brian was impressed with the level of information provided but was able to add something. He did request that I perform a specific test cut and record a video of it.

The test is a 3" x 3" square, with no rules implemented, running book speed which is 85ipm, and 0.5 pierce delay at 45 amps.

He asked that I also do a pressure check on my 45XP; this is done by holding the mode button on the front of the machine, and letting it go when “PC” appears on the display.

The number that flashed was “66”. After which, the torch began to push air as if the torch was “on” and the front display fluctuated between 65 and 66.

Brian had stated that as much as 2psi is within range whereas my own machine varies by as little as 1psi.

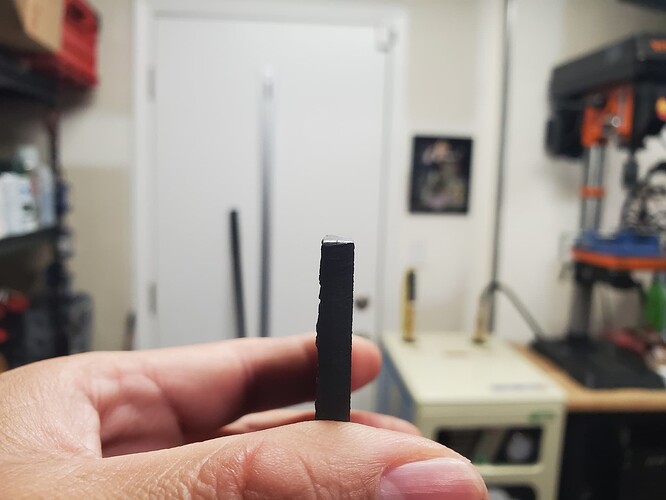

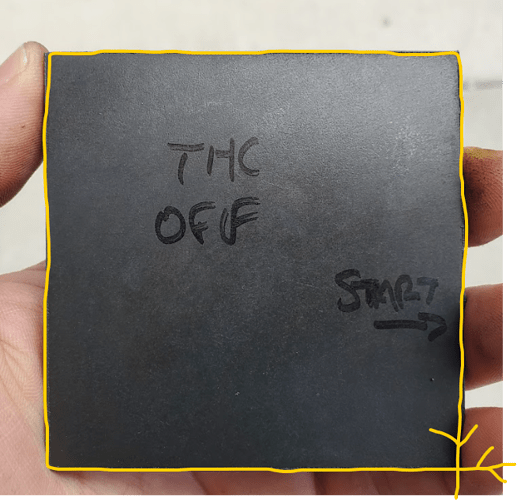

Now the results of the 3" x 3" square are interesting -

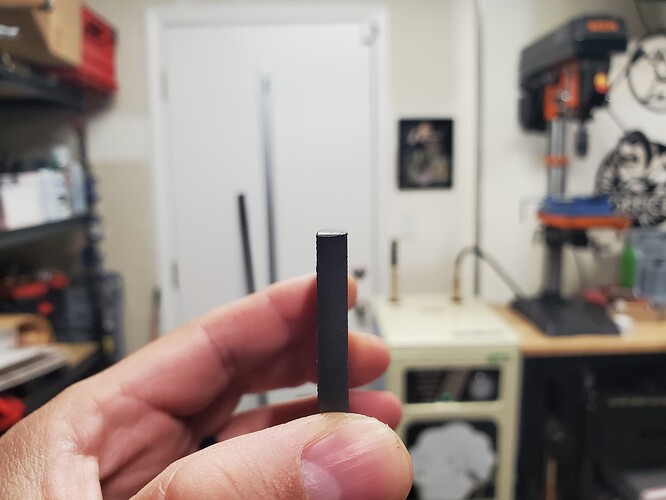

Top edge

Bottom edge

Left edge

Right edge

The test piece here is what I would call more than acceptable, and what I would or should expect my cutouts to look like.

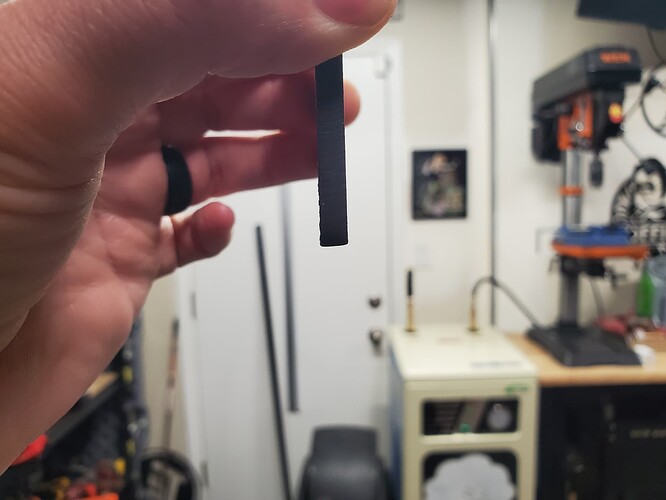

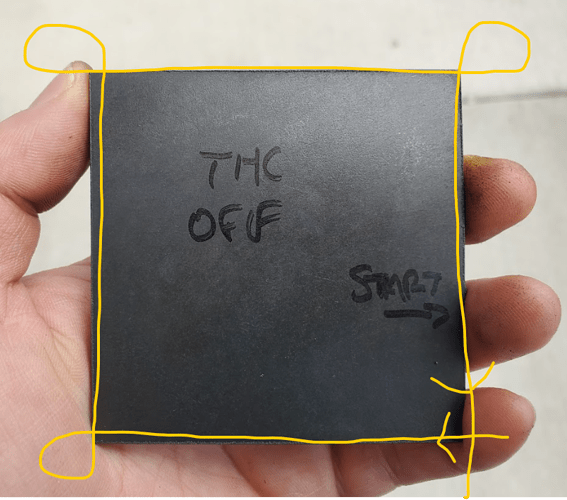

Performing the same test but beginning with the lead in on the left side provided identical results -

Top edge

Bottom edge

Left edge

Right edge

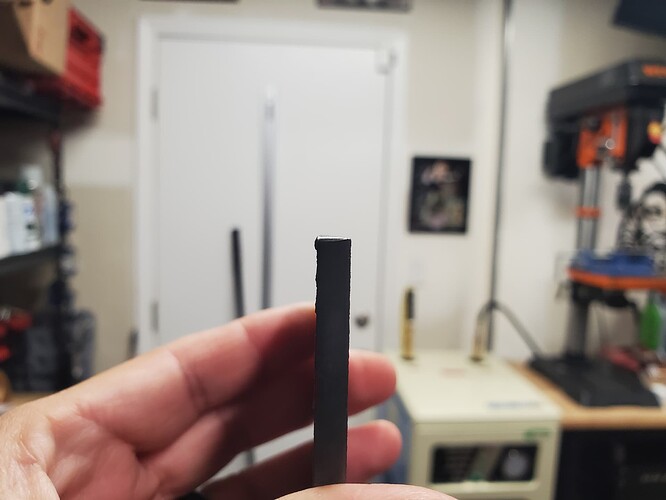

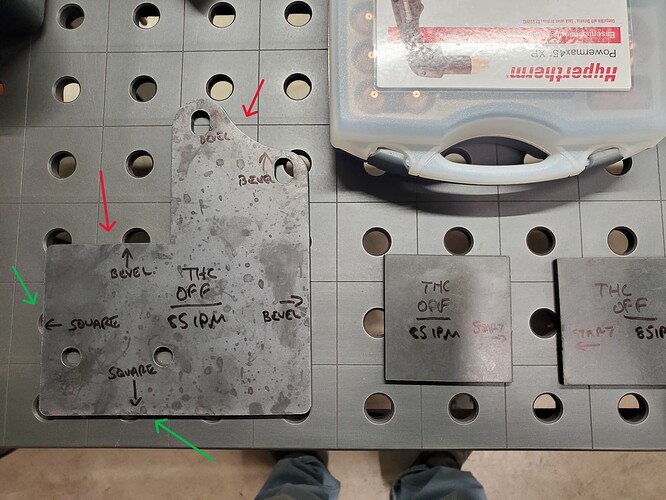

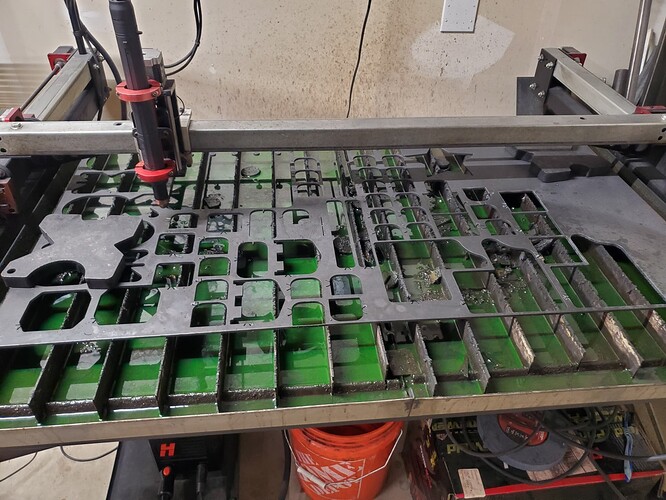

In the same area of my steel sheet, I opted to cut one of my vehicle parts using no THC, with the same 85ipm cut speed and cut height as the above 3" x 3" pieces.

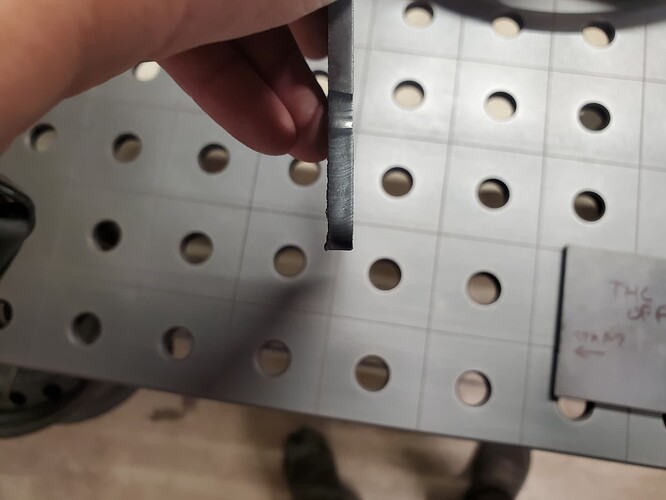

Results were the same as every piece yesterday, day before, and day before that with a bevel up top, and square bottom and oddly enough even, now a beveled right side but square left side

Top edge

Bottom edge

What strikes me as odd is how the top edge, being a 3 1/4" straight edge, can have such beveling while the 3" x 3" square, on the same axis, does not even with the same parameters. And yes, before you ask, the bevel is not just at the radius but extends through the entire length of the top edge.

Since I was able to perform a great 3" x 3" cut out, I want to chalk this up to a user-end issue (ME).

But, I’m not sure where to start considering I’ve ran with and without THC in my testing, I’ve tried everything from 123.5v to as high as 130v nominal, as well as having smartvoltage running for a programmed cut height of .025" (which measures to .06" with feeler gauges).

I have run speeds as low as 60ipm to as high as 90ipm, including Langmuir’s test file that ran at about 72ipm or something like that.

Here’s the test file if anyone wants it, as the processing was done on their end

Test Cut RTC.nc (1.1 KB)

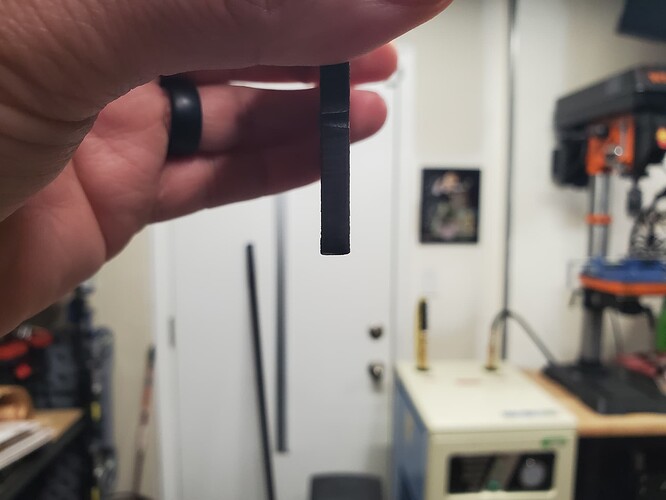

Running their file, also resulted in a square bottom edge and top beveled edge like my truck part.

![]()