@brownfox Your reply came in as I was typing, so I am adding this as a response to you, then you can continue reading below.

After the last cut posted there was done, I proceeded to run the same exact file again, and see if I achieve the same results.

I ran the next test piece within 2.25" away from the last cut piece shown above meaning, in the same spot on the same piece of steel and every other variable being the same, just a good two inches over.

This resulted in a test piece with a perfect bottom edge, great squared edges on the left and right side, and beveling up top.

This was not an issue with my CUT60 and UPM-105 combination.

The torch mount itself is square, eccentric bearings tightened correctly, and running as it’s supposed to which you would know if it wasn’t because the Easyscriber would easily point out those flaws.

Anyway, moving forward.

Removing the CUT60 and UPM-105 was as simple as cutting the zip ties holding the torch cable, and unbolting the clamps on the torch mount; everything else remained untouched.

After installing the 45XP (new) with Duramax machine torch (new), I performed many test cuts all dating back to Friday or Saturday as shown above in this thread.

The common reoccurring issue as of yesterday is the pronounced bevel on the top edge of a cut out. It occurs in the X axis, and only on the top edge. Meaning, if you cut out a square, the opposing edge (bottom) is square even if the top edge is beveled.

This lead me to believe my torch and/or mount was canted in some way.

Torch was dismounted and remounted over 15-20 times, going as far as undoing the bearings (multiple times), and following the order of operations for tramming the Z axis and ensuring it is completely square. Even after having done so, I would proceed to run a test cut, dismount everything, loosen the bearings, undo the set screws a bit, and redo it all over again.

After troubleshooting various methods yesterday, I called it a day.

This morning, I removed the freshly used (and genuine) Hypertherm consumables, put in new Hypertherm consumables, and decided to start from zero once again.

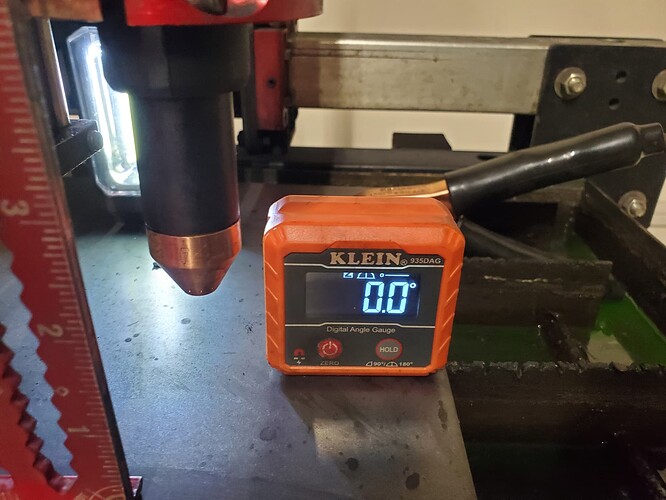

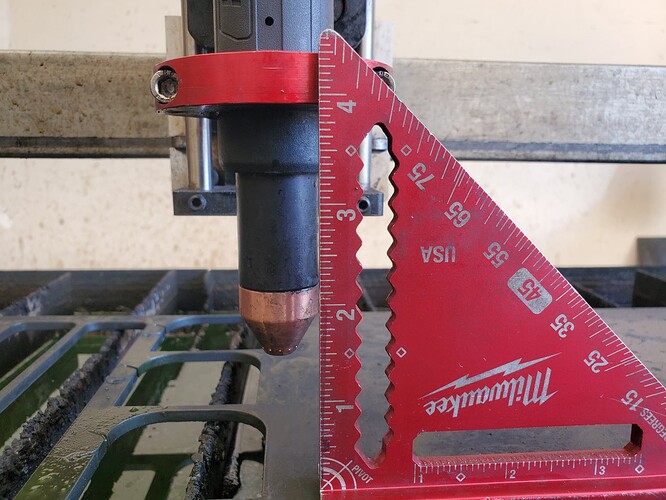

So back to torch squaring (this is after having redone the bearings AGAIN)

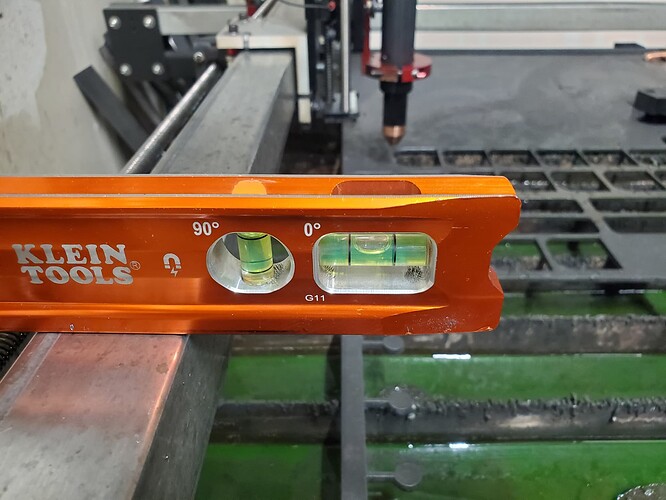

Ensuring the gantry was level both ways as well.

As well as the other tubes.

Even the work material matches that of the table.

And even though I didn’t take pictures (hard to), I had also checked for square on the front and rear portion of the torch assembly (with torch removed).

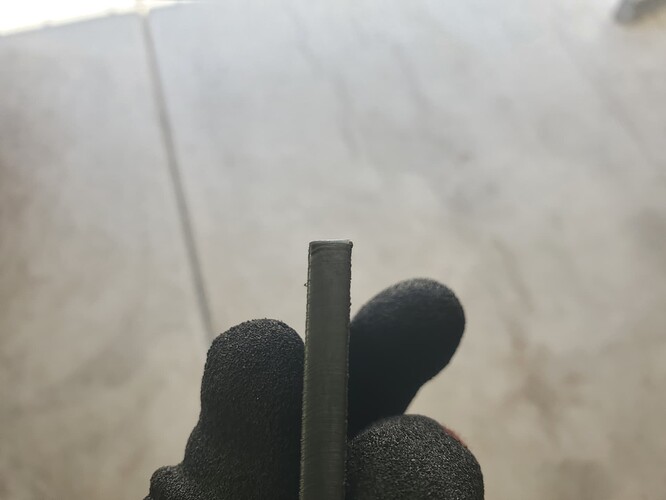

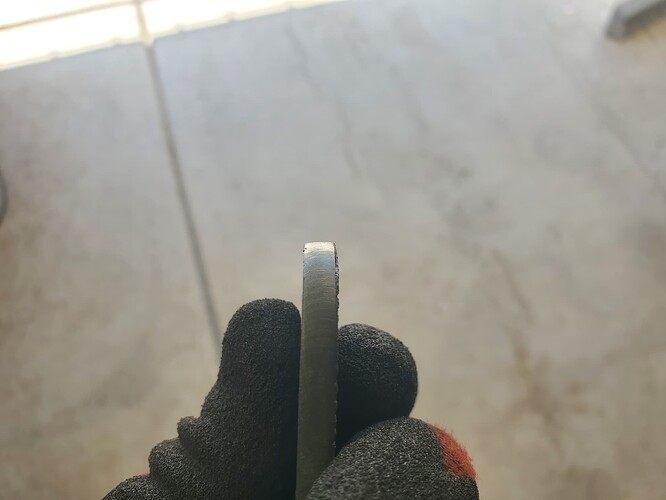

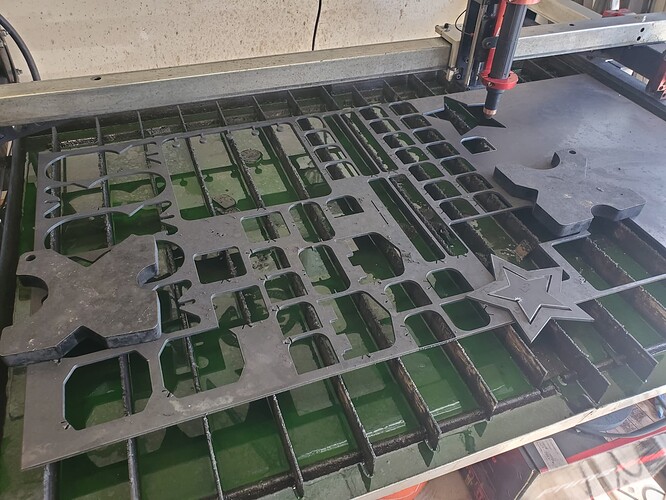

In this picture shows the top edge of many different pieces which include -

*THC having been turned off

*Machine torch having been rotated (ensuring the torch itself wasn’t causing the bevel)

*The CAD design having been rotated (that’s the 3rd piece from left to right, the bottom edge was perfect, top edge still beveled even though it’s now a different geometry)

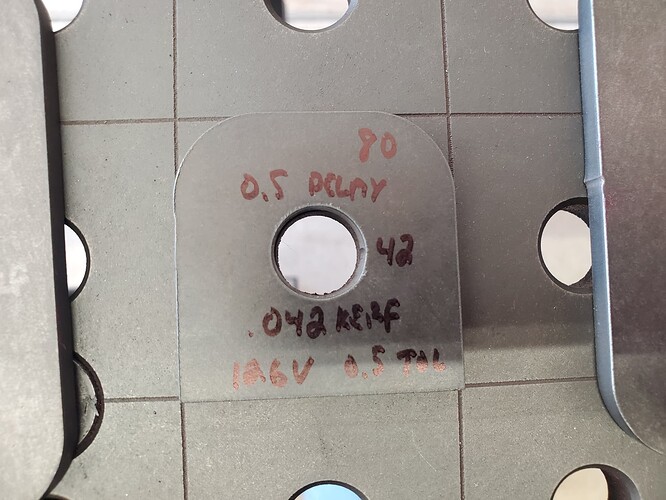

*As well as a few runs in nominal voltage ranging from 123.5, 124.5, 125.5, 126, and 129, as well as speeds from 60, 80, and 90ipm

*As well as Langmuir themselves taking the DXF of this same item and performing post processing for me to run which I did - the unique thing to add is that in MY post processing, the top edge is the second edge being cut out in a clockwise direction however, Langmuir did post processing ensuring the top edge was the last edge being cut in a clockwise direction

*Oh and also including having run smartvoltage as well for a confirmed height of .06"

Not all the pieces I described being cut in that manner are the pieces in my hands, just a handful but they all experience the same pronounced bevel up top

I also intentionally ADDED some cant to my torch by shimming the torch itself once, then a bit more a second time

Here you can see that I’m cutting in different areas of the table with the same issue.

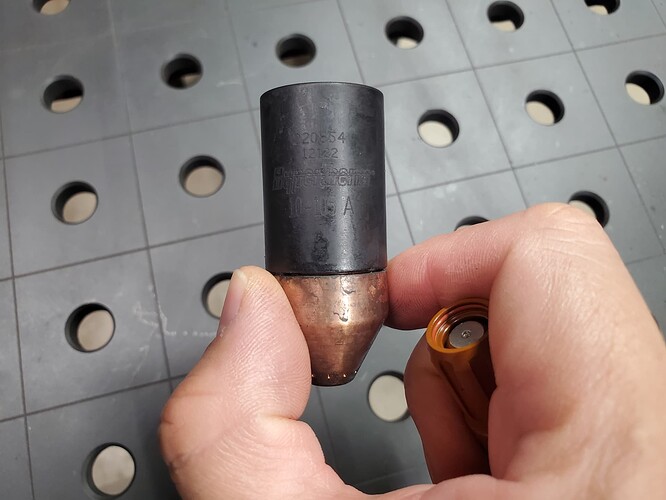

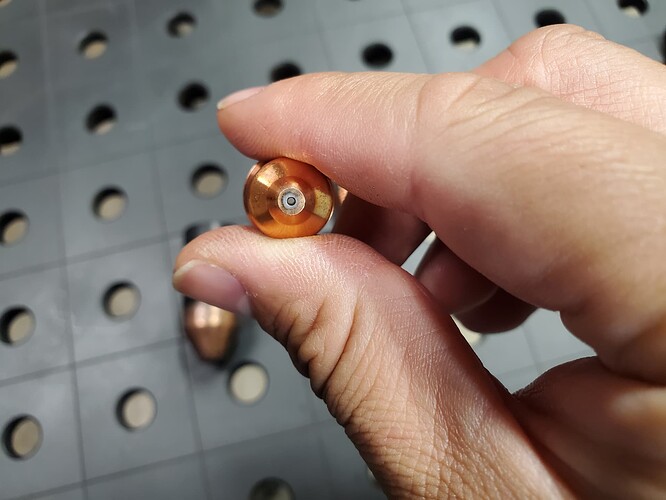

As well as pictures of my genuine consumables with part numbers shown - these are new as of today and all pierces are just for today’s test cuts.

And lastly, I’ve tried 100psi, 110psi, and 120psi to my Hypertherm and still had the same results.

I run a refrigerated air dryer, desiccant filter, coalescing filter, and a motorguard filter all before it reaches the water separator on the Hypertherm (which is dry to the bone).

So to summarize, cheap plasma cutter with cheap torch gave me square cuts all around. Install expensive plasma cutter with expensive torch and expensive consumables, lots of beveling on the top edge even after altering many variables and confirming everything is good.

PS The square cuts done on the CUT60 were as recent as a day before the Hypertherm was put to work.