This is becoming quite the subject.

@manoweb I think it’s awesome that you went as far as to call the manufacturer.

I’m going to post a couple things that leads me to believe that clockwise is the correct direction in most cases.

Start with a quote from @jimcolt . This was from the hypertherm website.

"The very early systems from the 1960’s created a plasma arc using something

called laminar gas flow. The gas flowed straight down through the torch so

cut direction didn’t matter. The torch would produce an equally bad cut, with a

severe bevel, on both sides.

Plasma process engineers were obviously aware of this limitation and spent

years trying to overcome it. Eventually, engineers discovered they could reduce

the angle of the cut by swirling the gas flow through the consumable stack.

There was one constraint however: you could only improve cut quality on one

side of the kerf. Swirl the gas clockwise while the torch was moving away from

you, and you’d get a rather severe bevel on the left side of the torch and a slight

bevel on the right. Swirl the gas counterclockwise, and the opposite cut issue

would occur. The left side would have the slight bevel and the right side would

be severe.

Engineers have continued to refine gas swirl through the years and though the

bevel is much less pronounced on both sides of the kerf, there is still a good

side and a bad side which is why cut direction matters.

On some plasma systems there are available swirl rings that can swirl both

clockwise and counterclockwise. If, as an example, you are using two torches

simultaneously to cut strips from a plate, you could use a clockwise swirl in the

left torch to provide a square kerf on the right and a counterclockwise swirl on

the right torch to obtain a square kerf on the left.

That said, nearly all (99.9 percent) plasma cutting is done using a clockwise

swirl. A good way to remember the proper cut direction is to think of cutting a

ring. The inside diameter is always cut in a counterclockwise direction, while the

outside diameter is cut in a clockwise direction. This keeps the squarest edge

on the inside diameter and outside diameter of the ring, and the more beveled

edge stays in the scrap.

Most CAM software for plasma cutting (the key word here is “most” since

software designed for milling or routing often allows the programmer to set

direction) will automatically choose the correct direction. As the standard swirl

rings for plasma cutting are always clockwise swirl, counterclockwise swirl rings

are rarely used and in fact, are not even available for many plasma torches."

Here’s a graphic that illustrates the above text very well

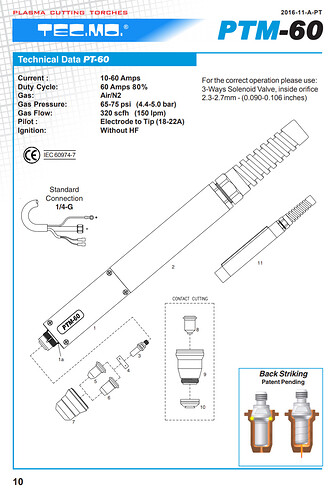

And I want to dive into some TEC.MO documentation

http://www.tecmo.it/upld/repository/File/2016-11-A-PT.pdf

When I look at these spec sheets and breakdowns of all these tecmo torches.

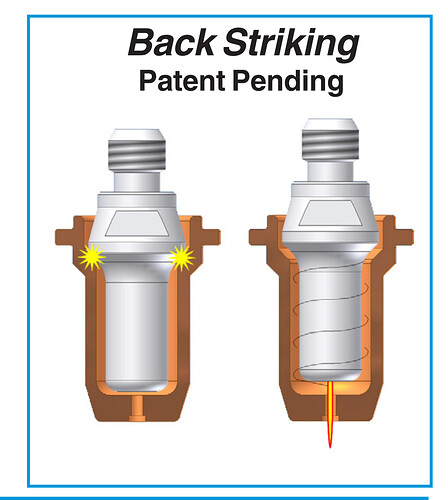

Each one has this graphic for the back striking which does clearly show the swirl moving down the electrode clockwise.

All this leaves me with this question.

Why create a swirl ring with directional holes if it does not matter which direction it is installed?

![]() which one is it, A or B?

which one is it, A or B?