Thank you, I believe that I’ve seen that before just wasn’t sure which one you were using.

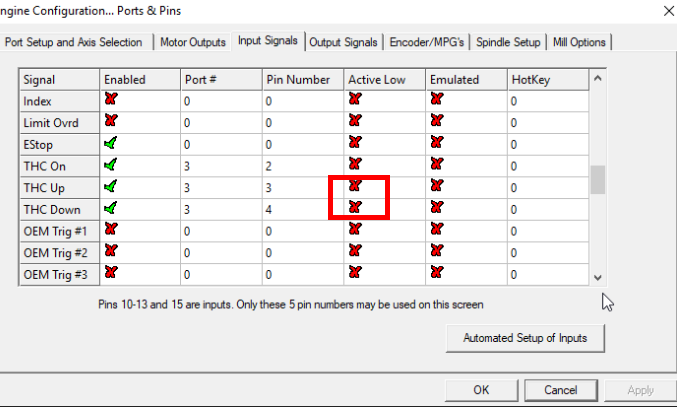

That’s my write up… If it’s from Vietnam, it’s most likely the one I used… FYI, you don’t want the up/down model on any other THC… But that one can be used both ways, up/down or step/dir, it just depends on how you wire it. up/down will not work with the langmuir bob, you have to use step/dir. I found out from someone else on this forum, after I had already wired it for up/down. Mach3 recognizes it, but it just doesn’t do anything else… I was told that it was because the langmuir board doesn’t support it… The comments are in my thread in this forum: THC step by step

This is the one I ordered, and reference, if you got something different, I don’t know…

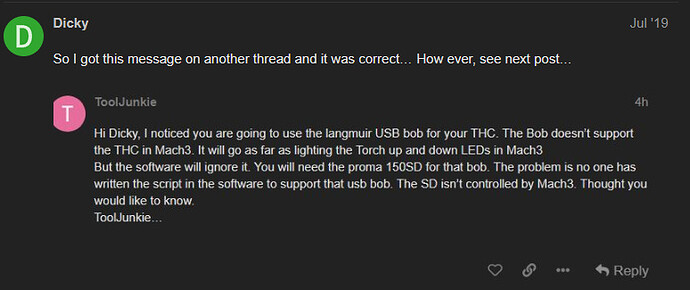

So this is what was on that thread…

That lead me down the path to finding out that this THC could be wired both ways…

Now looking at it, and just wondering… I wonder if I would have changed these to active low, would it have worked??? I found out later after all of this that I had to change some other setting to active low for my Z to work at all… Eh, maybe when I build my next box… LOL

In any event, it works just fine in the step/dir mode… I did use the arc ok from the thc, and I can use the thc on/off in mach3. I sometimes do that on smaller circles, it will wait for the arc ok signal before moving x,y so sometimes the holes come out cleaner…

Thank you for the explination, I have everything to do the z axis upgrade except for the THC unit itself, that’s why I was wondering which unit is the best, I will probable just follow tooljunkie and get the 150sd.

Thank you

Thats the one I ordered, except I ordered the one with the Voltage divider… After I ordered it I realized I did not need the voltage divider, but it was only $30 more… just a extra part that I will not be using.

So if I understand what I think that I know, your way lets Mach3 control the movement of the z axis and tooljunkie way is a stand alone unit that controls the z axis without using Mach3?

I guess it is dependent on my plasma cutter weather or not I need the divider?

Primeweld cut60 is the one that I have if you happen to know if I need the divider or not?

Thanks

I like the way it looks. You could make a working sample, it reminds me of a listener, you know, these used to be revolvers, if you can call them that. It’d be great how the exhibit looks interesting, but I’d still work on the handle.

Thank you for showing me your work!

The up/down method is “supposed” to let mach 3 control the Z axis, but it doesn’t work, at least no one has been successful at it. Everyone is using the step/dir method which controls the Z axis independent of mach3

Well, my impression is that the motion controller in the Crossfire is a smart controller, not a dumb ‘BOB’ that simply passes through the step pulses generated by Mach 3. So, in this case, the motion instructions are passed down from Mach 3 and the step/dir signals are generated by the Crossfire controller. This includes the two ‘spare’ axis in the controller (A & Z) so, in Mach 3, you may have controls that set the mode of the output signals, but, in reality, they probably have no affect (other than possibly polarity, etc) on the actual output pins. Hence, you can have Mach 3 ‘move’ so many units in Z, but the pulses are generated in the controller. This is why you can have Mach 3 run on a dumb/slow laptop over a USB connection that emulates a 9600 baud serial port and it still works. Most of the processing takes place in the controller.

@TomWS I’m not sure what you just said, but if you get mach3 to run an up/down THC with the Langmuir breakout board, then by all means post your wiring schematic, settings, and some videos. We are all waiting!

Well, I guess I didn’t make myself clear. I didn’t say that I could get Mach3 to run up/down THC, it can’t on a CrossFire precisely because the controller in the CrossFire generates the step pulses, not Mach3, and the only kind of pulses the controller knows how to generate are Step/Dir pulses (with the current SW). I also don’t have THC.

My “production volume” is approximately one cutout every week or so ![]() so I can take the time to clamp down my workpieces. Maybe someday as the technology interests me, but I don’t have a legitimate need…

so I can take the time to clamp down my workpieces. Maybe someday as the technology interests me, but I don’t have a legitimate need…

I am, however, enjoying the work you and others are doing in this area. Thanks!

Ah, I get it now, thanks for the clarification… i’m an electronics illiterate! I’m actually surprised I pulled that off with no magic smoke!

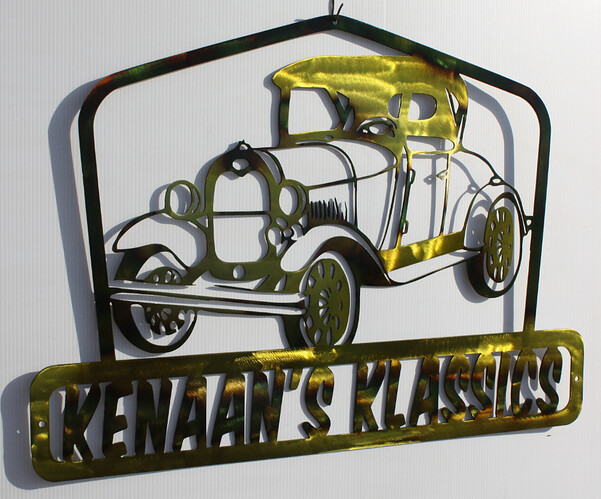

Well, another productive night in the garage… My Uncle’s birthday, and he has 7 perfectly restored Model A’s that he and my dad did frame off resto’s on…

And another Trump Flag… tried changing it up with the flap disk, instead of just one direction, put some squiggles in it… Not bad, working on the technique. Saw a guy on another thread that can make it look like flames! It’s pretty awesome!

Nice looking projects, is that paint or powder coating?

Metal cast paints, and I put them in an oven to dry

Had nothing to do with the Langmuir table but even with 84 hours at my regular job last week with an hour drive each way and 73 hours this week I managed to squeeze in a lowering project to help out a friend. My wife asked my why I would do it and I told her that I had a few extra hours with nothing going on, she said I was crazy, she’s probably right.

2020 GMC Sierra lowered 4 inches in the front and 6 in the back.

Before

After

Sure made it look alot nicer I think.

Where I come from and go, you’re supposed to RAISE them 4 inches!

Man Dicky I’m glad I haven’t been on here in awhile my wife would’ve killed me if she saw this.

(post withdrawn by author, will be automatically deleted in 24 hours unless flagged)