How do I resume cutting a partially fininshed program? Like scroll down through the program and start somewhere other than the begining?

Click on the spot where you want to start in the visualizer. That should bring up a menu to run from line or start from loop. If you want to start at the beginning of a cut loop, select run from loop. Run from line will not start exactly where you click, but it will go back to the last line of code in that loop

Clicking that will generate a new program from that point forward. Click start.

Thank you!

unfortunately when i generate from a loop it does generate it but it’ll “dry run” it wont strike an arc… very frustrating on larger pieces since it gets 80% of the way done and i cant get it to finish im just losing my butt in materials at the moment

That is another glitch in the Fire Control that we hope they will fix.

Best way is to find the line (not code line) of where it failed and cut it again this will be a "Run From Line (code) command. Not the best since re cutting tends to remove more material from the part. Sometimes it will be after the failed cut and you will have to go back with a hand torch or cut off tool to finish it.

When I run into this, I have to reload the original program, do any rotation or origin changes that I did the first time, then find the cut line I need to start over on and then run from loop or line.

ya ive had success doing that in the past but at the moment im just re loading it and trying, ive gone from loop, from line, ive tried all sorts of stuff and cannot get this thing to do anything other than dry run from selected line.

There might be a way to tweak the file from FireControl (upload button) then open in a text document and insert the torch start commands. I have not played with that option yet, I just know that uploading the file from FireControl, then trying to load it and run it will create a “Use correct post processor” error.

Are you hitting duty cycle on your plasma?

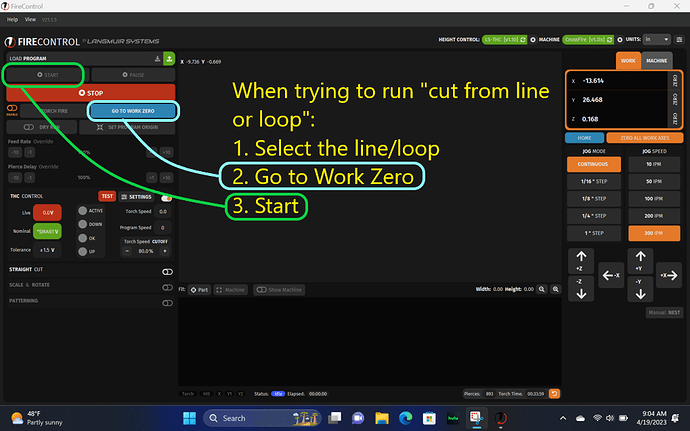

I have heard others say that before you hit [START], go back to [Work Zero]. Perhaps this adds that extra delay that helps with the start of the arc. I am not sure. But, I have always followed this practice and it seems to work. If you try it, let me know if this instruction was not helpful.

I’ll have to look at that when I get my trailer back. In transit.

I still think there is a glitch in FC that when you generate the “Run From” it is not producing the torch commands.

i dont believe it was duty cycle, what i find is when my compressor kicks on it loses arc, then it is a struggle sometimes to get it to initiate its ark again, other times it just starts and runs like normal from any loop and line seems like a glitch or just finicky, i read on here others having the same problem with the compressor/arc so i took their advice and just pause the program when the compressor kick on and i havent really had to worry about it to much anymore

nex time i encounter this ill definetly try that, that could be a very good possibility.

no it was mainly when the comperssor would kick on the table would lose arc. even if it was the first section of the first cut of the day. i just pause the program till the compressor is good and run it.

I would check for voltage drop then.

Power to the plasma is being pulled when the compressor starts.

the table and compressor are each on their own 50 amp breaker, as well as voltage drop would directly show in the torches live readings i would assume. this is kicking the compressor on and losing a split second of air and shutting down.

and i think a voltage drop would show in the torch live readings as well, i sat there and stared at everything and the only change is the lack of air for a split second. we own/operate a welding business i can crank the welders up while cutting and not lose any voltage and the compressor is the “smallest” of the lineup, to be putting a strain or drawing power.

Then it is a air pressure drop causing you to lose arc?

What size compressor are you running?

ya i believe its a fraction of a second of air prressure drop, im running a kobalt 5hp 80 gallon two stage compressor. 17.1 scfm @ 90psi

I would check for air flow restrictions. You should never see enough pressure drop with that big of a compressor unless you have the kick in real low. What is your pressure coming into the plasma?

so i have the compressor kick on @120, its flowing to the machine around 75