Hey guys I’m finally getting around to cutting stainless steel 304 on my Razorweld. I do want to get everything right on my first cuts. What would be good cut settings that you would recommend to me? Thank You!

Johnny, good to see you on here!

Watching the thread to catch some recommendations here from others.

This is on the Hypertherm 45XP yes?

YOOOO man how are you?! The plasma cutter is going to be a Razorweld 45

Ah cool got it.

I’ll try to tag one member I think that has the Razorweld 45.

And everything is great; hope you got the memo from Jake. I told people in the other thread how you specifically stuck it out to try and help me in my issue with the Hypertherm.

So thanks again.

@Knick think you said you have the RW?

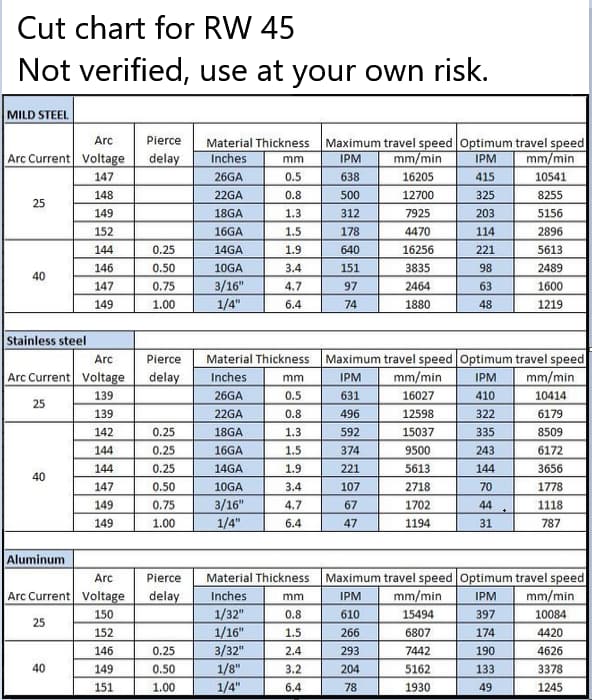

Here is a chart that I have seen a few times referred to but I do not have your cutter so I can’t confirm or deny that it is helpful.

Tin says you’ve got to keep it cool so fill the bed up with water and have a bucket to splash on while cutting. If you have fine cut consumables (not listed on this chart) but certainly worth trying.

I do have the RW 45 but I have never cut stainless. I have cut 16 ga hot roll and it would have 45 anmps and maybe 160ipm. I am not aware of any fine cut consumables for the RW

While you are trying to dial in your settings, this article has some good common sense ideas of issues if the speed is too slow or too fast.

How to troubleshoot cut quality problems – too much dross (slag).pdf (309.8 KB)

Here is a previous post that compiles a bunch of ideas for better cuts but not specifically for stainless. The part I wanted to point you to is what George said about tip size. “It’s not the size that matters, it is how…” Never mind. Wrong thread ![]()

George talked about the different size tips and the amperage range of each tip. That might be helpful as we have found that a smaller tip will give better results with stainless.

What happened to the 52i you were asking for settings for?

Here are a few things I do when cutting stainless.

-Peel the plastic film from material.

-cut height .02" pierce height .08"

-short as possible pierce delay

-cut as fast as possible while maintaining geometry

(start with 35 amps at 200ipm,I have a powermax 85 so I am taking a guess here)

-Pour water on sheet during cut if geometry is complex and could build up heat.

-(with the Powermax I use Finecuts unshielded)

This is my rough approach when cutting stainless with my power max you will need tweak these for the Razerweld.

All of those tips in one post!!! That one is bookmarked.

Now BigDaddy gets excellent results with F5 gas vs compressed air. What settings do you use @Bigdaddy2166 ?

Never cut 18 ga Stainless steel. The Everlast cut chart is dead nuts on, though. I don’t know about the razorweld. The F5 gas just keeps the edges from oxidizing. Almost all my Stainless steel is 10 ga and above.

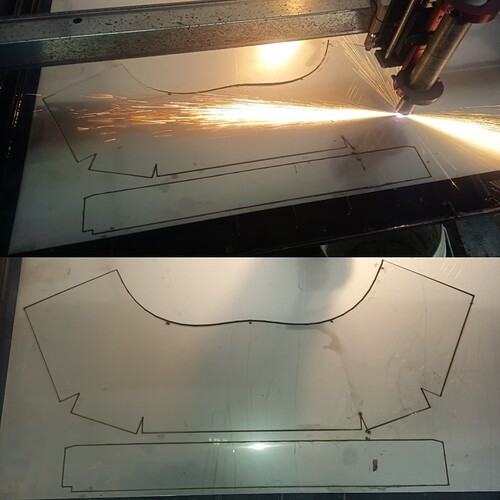

Hello Sir, I recently cut a bunch of 10ga. stainless using compressed air and results were impressive. Of course a little clean up is required especially due to the sugaring edges on the back side, but nothing unbearable as SS cuts are not requested often. I also use the Razor cut 45 on the Crossfire XR. I will share my settings when I get home this afternoon.

Sorry for the delay, just back in town. My settings for 10ga stainless are:

Regular nozzle

Feed Rate: 100 ipm

Pierce Delay: 1.2 s

Pierce Height: 0.15

Plunge Rate: 50 ipm

Cut Height: 0.0625

AMPS: 40 Razor Cut 45